Static Control I: Electrostatic Discharge and Prevention

Sponsored byDESCO INDUSTRIES INC.

In a technologically integrated environment, static electricity can be damaging, expensive, and in some cases, lethal. Most people know static electricity as the minor shocks encountered in everyday life when touching metals like door knobs, after walking over lushly carpeted floors, or even when sliding over a car seat. These shocks are static discharge events known as electrostatic discharge (ESD). While a shock from a door knob is seemingly harmless, in the industrial setting ESD can be a severe problem, potentially causing damage to electronic components. The use of ESD products such as wrist straps, foot grounders, grounded work surfaces, ESD shielding packaging, ionization products and other measures can help in preventing ESD events. This learning module discusses the main causes of ESD, its damages, and prevention techniques with a few application examples.

2. Objectives

Upon completion of this module, you will be able to:

Explain static electricity and electrostatic discharge (ESD)

Explain static electricity and electrostatic discharge (ESD)

Describe the leading causes of electrostatic discharge and damages due to ESD

Describe the leading causes of electrostatic discharge and damages due to ESD

Discuss the prevention of ESD using protection devices

Discuss the prevention of ESD using protection devices

Understand control programs to avoid electrostatic discharge

Understand control programs to avoid electrostatic discharge

Electrostatic discharge (ESD) is an unsolicited electrostatic charge transfer when imbalanced electrical charges induce a high electrostatic field on or within a material surface. Visible sparks are created when individually charged objects touch or are brought into close proximity. One familiar example is lightning, a massive-scale ESD event. Even in its less dramatic form, an ESD can be sufficiently large to damage sensitive electronic devices, and because of this ESD influences product reliability and productivity in every industry. The electronics industry uses a variety of ESD-safe antistatic products to prevent damage from ESDs.

At its most basic level, ESD occurs when imbalanced and opposite electrostatic charges accumulate due to two surfaces coming into close contact. These charges may accumulate on or within both surfaces to generate an electrostatic field. These accumulated charges are at rest and are termed static electricity.

Static electricity may also be caused by electrostatic induction or tribocharging. Electrostatic induction is the dispersal of an electric charge on a material caused by a charged object nearby. The presence of electric force between charged material particles causes a negatively charged object brought in proximity to an electrically neutral object to induce a positive charge on the neutral object's near side, and a corresponding negative charge on the far side. Additionally, the neutral object may become positively charged via induction if its negative side is briefly grounded to permit the negative charge to escape. Electrostatic induction is unavoidable if an object is put within an electric field.

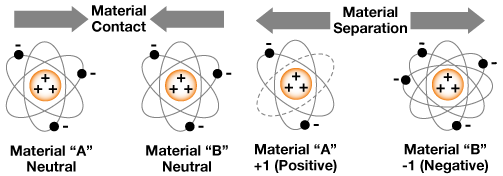

Triboelectric charging occurs when an electrostatic charge is formed due to contact followed by separation of two or more materials. For example, walking over a carpet involves multiple contacts and separations between shoes and carpet. The atoms of a zero static charge material contain an equal number of positive  protons inside the nucleus and negative

protons inside the nucleus and negative  electrons in orbit outside the nucleus. Figure 2 shows the triboelectric charging process between two materials, "A" and "B." Both materials consist of atoms with equal numbers of protons and electrons, and thus they are electrically neutral.

electrons in orbit outside the nucleus. Figure 2 shows the triboelectric charging process between two materials, "A" and "B." Both materials consist of atoms with equal numbers of protons and electrons, and thus they are electrically neutral.

Figure 2: Triboelectric Charging (Contact & Separation). Image Source: EOS/ESD Association, Inc.

Positive Positive |

Negative Negative |

|---|---|

| Fur | Sealing Wax |

| Glass | Nickel, Copper, Brass, Silver |

| Mica | Gold, Platinum |

| Human Hair | Sulfur |

| Nylon | Acetate Rayon |

| Wool | Polyester |

| Lead | Silicon |

| Silk | Teflon |

Table 1: Triboelectric series table

When both materials are touched and then parted, negatively charged electrons are transferred between the two material surfaces. The nature of these two materials determines which material loses electrons and which one gains electrons. Positively charged materials lose electrons, while negatively charged materials gain electrons. The amount of triboelectric-generated charge depends on the contact area, separation speed, surface work function, relative humidity, material chemistry, and other factors. The newly produced electrostatic-charged object transfers this charge and generates an electrostatic discharge event.

Charges of any magnitude or polarity will seek to balance that charge. Conductive objects will do this very readily. When two conductive objects with different charges come into contact, they will balance their charges. This is an Electrostatic Discharge.

The material’s characteristics affect the magnitude and polarity of the charge generated by the triboelectric charging process. Table 1 illustrates the triboelectric series and how different materials create charges.

- 3.1 ESD Types

Generally, three types of ESD events cause damage: direct ESD to the device, ESD from the device, or field-induced discharges. The device's endurance determines the harm suffered by an ESD-susceptible item (ESDS) against abnormal voltage levels. A device's ESD susceptibility or ESD sensitivity refers to its failure threshold.

Direct ESD to the device occurs when a charged material directly transfers an electrostatic charge to an ESDS. An individual walking over a floor may accumulate electrostatic charge on their body. ESD damage is possible when this individual physically touches or even comes close to an ESDS or an assembly lead with a different electrical potential. The body may discharge and cause ESD to harm the ESDS. The model employed to simulate such an event is termed the Human Body Model (HBM). The other model is known as the Charged Device Model (CDM), which describes the metal-to-metal contact that was formerly associated with the Machine Model (See Glossary). The CDM voltage level as used in this document is based on managing process essential insulators to mitigate field induced voltages on devices that could lead to damage.

Direct ESD to the device occurs when a charged material directly transfers an electrostatic charge to an ESDS. An individual walking over a floor may accumulate electrostatic charge on their body. ESD damage is possible when this individual physically touches or even comes close to an ESDS or an assembly lead with a different electrical potential. The body may discharge and cause ESD to harm the ESDS. The model employed to simulate such an event is termed the Human Body Model (HBM). The other model is known as the Charged Device Model (CDM), which describes the metal-to-metal contact that was formerly associated with the Machine Model (See Glossary). The CDM voltage level as used in this document is based on managing process essential insulators to mitigate field induced voltages on devices that could lead to damage.

ESD from the device occurs when an ESDS transfers the charge to a conductor. The ESDS may accumulate static charge by coming into contact or rubbing against packaging materials, machine surfaces, or work surfaces. This frequently happens when a device vibrates inside a package or moves over a surface. The model employed to simulate such an event is termed the Charged-Device Model (CDM). Automated assemblies may suffer from CDM.

ESD from the device occurs when an ESDS transfers the charge to a conductor. The ESDS may accumulate static charge by coming into contact or rubbing against packaging materials, machine surfaces, or work surfaces. This frequently happens when a device vibrates inside a package or moves over a surface. The model employed to simulate such an event is termed the Charged-Device Model (CDM). Automated assemblies may suffer from CDM.

Field-Induced Discharges: Field induction is yet another electrostatic charging process that may directly or indirectly harm devices. Any electrostatically charged object produces an electrostatic field, and when a grounded ESDS is placed inside this field, a CDM event occurs. A second CDM event may happen if the item is removed from the electrostatic field and then grounded again.

Field-Induced Discharges: Field induction is yet another electrostatic charging process that may directly or indirectly harm devices. Any electrostatically charged object produces an electrostatic field, and when a grounded ESDS is placed inside this field, a CDM event occurs. A second CDM event may happen if the item is removed from the electrostatic field and then grounded again.

- 3.2 Harmful Effects of ESD and Failure Types

ESD damages electronic components in multiple ways. Large static voltages may burn the internal circuitry of a device. Extremely high voltages may wreak havoc in the compact conductor and insulating barrier. Because of miniaturization, the miniscule sizes of integrated circuits and other components has made devices more vulnerable to static electricity damage. High input impedances enabled by metal oxide semiconductor (MOS) technology hamper voltage dissipation and have only amplified the ESD effects.

ESD damage can occur at any point, from manufacture to field service. The damage is usually classified as either a latent defect or a catastrophic failure. ESD-related catastrophic failures include metal melt, junction breakdown, or oxide failure within the device. The terminally damaged device circuitry can cripple the equipment. In a latent failure, the ESD may cause partial device degradation, even as it executes its desired function. Latent defects are difficult to detect and special attention should be paid to identifying them; as such, ESD damage may culminate in equipment failures down the line, thus reducing reliability.

- 3.3 ESD Standards and Testing

The ESD Association approves and publishes the Electrostatic Discharge Control Program (ANSI/ESD S20.20), an ANSI standard. The ANSI/ESD 20.20 includes both technical and administrative provisions customized to specific applications or requirements. The administrative sections cover the progress of an ESD Control Program Plan, Training Plan, and Compliance Verification Plan with routine audits. The technical requirements cover grounding, personal grounding, protected areas, packaging, labeling, equipment, and handling. ESD testing refers to the process in which a device is tested for its resistance to ESD. It is classified into three main categories: human body model (HBM), machine model (MM), and charged device model (CDM). The EN/IEC 61000-4-2 is the most common standard for ESD testing.

We will now analyze how to protect a device from ESD, discuss various ESD protective devices, and describe control programs in the electronics manufacturing environment.

- 4.1 Basic Principles of ESD Prevention

It is a challenge to control electrostatic discharge (ESD) in electronics. However, there are four basic principles for ESD control:

Ground all conductors, including people and work surfaces.

Ground all conductors, including people and work surfaces.

Use ionization when using process essential insulators or un-grounded conductors.

Use ionization when using process essential insulators or un-grounded conductors.

Shield ESDS when they are removed from an ESD-controlled area (EPA).

Shield ESDS when they are removed from an ESD-controlled area (EPA).

Manage a compliance verification program to ensure that the controls measures used are working.

Manage a compliance verification program to ensure that the controls measures used are working.

In the EPA, electrostatic discharges should be safely dissipated or neutralized, as it is impossible to eliminate electrostatic charge generation. Proper grounding and conductive materials should achieve this objective. Because nonconductive parts, such as common plastics and other insulators, cannot be grounded to reduce the charge in a reasonable time, an ionization process that generates negative and positive ions (Figure 3) can be employed.

ESD protection products should be used to shield susceptible parts and assemblies from inevitable random discharges. Various ESD control packaging and material handling products are available for extensive EPA use. These materials reduce in-container movement of products and, consequently, accidental charge production.

- 4.2 ESD Control Programs

Most environments require a judicious mix of ESD control programs. A single procedure is not a cure-all. Although each company is unique concerning its ESD control needs, at least six crucial elements are necessary to successfully develop, implement, and maintain an effective ESD control program.

Establish ESD teams and Appoint an ESD Coordinator

Establish ESD teams and Appoint an ESD Coordinator

A team approach is particularly applicable to ESD, as problems and solutions involve different functions, suppliers, departments, and divisions. The ESD team composition should include a wide variety of personnel from the company, including people with responsibilities overseeing incoming inspection, automation, packaging quality, and training. The ESD coordinator leads the ESD team efforts.

Assess Organization, Facility, Processes, and Losses

Assess Organization, Facility, Processes, and Losses

The next step is to gain a thorough understanding of the environment and its impact on ESD. Facilities and procedures should be evaluated, paying special attention to ESD sensitivity data, in order to find areas that may cause ESD problems. The focus should include static generating materials, personnel handling procedures for ESDS components, and the presence of conductors which could come into contact with ESDS components.

Establish and Document an ESD Control Program Plan

Establish and Document an ESD Control Program Plan

After completing the assessment, a plan should be created, documenting all tasks, activities, and procedures necessary to protect ESDS items. Specifications and procedures should be written and distributed to all departments.

Justify Your Activity for Top Management Support

Justify Your Activity for Top Management Support

Given the severity of ESD risk, ESD programs are typically supported by management. Quality and reliability must be highlighted in reports, and the costs and pitfalls of ESD damage clearly demonstrated, including the potential effect of ESD on customer service and product performance.

Develop and Implement a Training Plan

Develop and Implement a Training Plan

All affected personnel must be properly trained to support the organization's ESD control strategies and programs. A written training plan is required for ANSI/ESD S20.20 documented procedures; however, companies have the flexibility of designing plans as they see fit.

Develop a Proper Compliance Verification Plan and Implement It

Develop a Proper Compliance Verification Plan and Implement It

An ESD Control Program must be constantly reviewed, audited, and developed, with adjustments made based on feedback or changes in environment or procedures.

- 4.3 Related Components: ESD Protective DevicesBack to Top

The potential for ESD events can be mitigated by using ESD protection solutions, such as those provided by Desco Industries. ESD solutions include personnel grounding, grounded mats, testing equipment, ionization products, shielding bags/packaging, and coating and laminating with specialty products.

Personnel Grounding

Products include wrist straps, foot grounders, and ground cords with multiple variations, designed to attach the body to ground.

Has silver impregnated polypropylene knitted on inside for superior conductivity

Has silver impregnated polypropylene knitted on inside for superior conductivity

Reliably removes generated static charges. Additionally, silver fibers are antibacterial to help keep the band and operator clean.

Reliably removes generated static charges. Additionally, silver fibers are antibacterial to help keep the band and operator clean.

Date coded: providing lot traceability to ensure quality control.

Date coded: providing lot traceability to ensure quality control.

UL listed: meets UL & OSHA requirements to ensure operator safety.

UL listed: meets UL & OSHA requirements to ensure operator safety.

For more available products Shop Desco

Packaging Products

Products include static shielding, moisture-vapor-barrier, clear dissipative, unique bag-in-bag, bags on a roll, and vacuum sealers.

Metal-in film laminate 0.0028" thick (2.8 mil) protects ESD sensitive contents from electrostatic fields and electrostatic discharges (ESD).

Metal-in film laminate 0.0028" thick (2.8 mil) protects ESD sensitive contents from electrostatic fields and electrostatic discharges (ESD).

<10 nJ discharge shielding energy limit test per ANSI/ESD STM11.31. Meets ANSI/ESD S20.20 and ANSI/ESD S541 requirements for ESD shielding packaging inside and outside an ESD Protected Area (EPA).

<10 nJ discharge shielding energy limit test per ANSI/ESD STM11.31. Meets ANSI/ESD S20.20 and ANSI/ESD S541 requirements for ESD shielding packaging inside and outside an ESD Protected Area (EPA).

Dissipative inner and outer surfaces Rs 1 x 104 to 11 ohms per ANSI/ESD STM11.11 and static control bag ANSI/ESD S11.4 Level 3. Allows bag to be used throughout an ESD protected area and grounded when placed on a grounded surface or handled by a grounded operator

Dissipative inner and outer surfaces Rs 1 x 104 to 11 ohms per ANSI/ESD STM11.11 and static control bag ANSI/ESD S11.4 Level 3. Allows bag to be used throughout an ESD protected area and grounded when placed on a grounded surface or handled by a grounded operator

OpenTop and ZipTop styles are available

OpenTop and ZipTop styles are available

Lead-free RoHS 2, REACH and conflict minerals compliant

Lead-free RoHS 2, REACH and conflict minerals compliant

For more available products Shop SCS

Economical and efficient method of shipping or storing circuit boards and other static sensitive electronic devices

Economical and efficient method of shipping or storing circuit boards and other static sensitive electronic devices

Constructed from conductive (1 x 102 to < 1 x 105 ohms) extruded high impact polypropylene plastic; provides superior strength and durability

Constructed from conductive (1 x 102 to < 1 x 105 ohms) extruded high impact polypropylene plastic; provides superior strength and durability

Chemical and moisture resistant

Chemical and moisture resistant

Economical alternative to injection molded products

Economical alternative to injection molded products

Meets ANSI/ESD S20.20 and packaging standard ANSI/ESD S541

Meets ANSI/ESD S20.20 and packaging standard ANSI/ESD S541

For more available products Protektive Pak

Dissipative Work Surfaces

These surfaces are designed to provide a surface that does not generate a static charge and will control the discharge rate from all conductors (including ESD susceptible items) that are placed on the surface. They include work surfaces such as 2-layer rubber, homogeneous vinyl, 3-layer, and field service kits.

Dissipative dual layer ESD worksurface: provides a worksurface that does not generate a static charge and will control the discharge rate from all conductors (including ESD susceptible items) that are placed on the surface. (worksurfaces mats must be properly grounded to remove ESD charges.)

Dissipative dual layer ESD worksurface: provides a worksurface that does not generate a static charge and will control the discharge rate from all conductors (including ESD susceptible items) that are placed on the surface. (worksurfaces mats must be properly grounded to remove ESD charges.)

NEW Nitrile rubber oil resistant compound: improved material compound limits oil absorption to improve electrical and physical properties through the lifespan of the material. May be used in soldering applications with flux and other chemicals.

NEW Nitrile rubber oil resistant compound: improved material compound limits oil absorption to improve electrical and physical properties through the lifespan of the material. May be used in soldering applications with flux and other chemicals.

Dissipative (1 x 106 to <1 x 109 ohms Rtt) top layer - limited lifetime warranty: meets ANSI/ESD S20.20 worksurface required limit and recommendation of ANSI/ESD S4.1 for contact with ESD susceptible items.

Dissipative (1 x 106 to <1 x 109 ohms Rtt) top layer - limited lifetime warranty: meets ANSI/ESD S20.20 worksurface required limit and recommendation of ANSI/ESD S4.1 for contact with ESD susceptible items.

Conductive (<1 x 106 Rtt) bottom layer - limited lifetime warranty: reduces the resistance to ground (Rtg) from the top of the surface to the groundable point ground and allows the material to be used with ESD workstation monitors.

Conductive (<1 x 106 Rtt) bottom layer - limited lifetime warranty: reduces the resistance to ground (Rtg) from the top of the surface to the groundable point ground and allows the material to be used with ESD workstation monitors.

Ultraviolet (UV) stabilizer additives

Ultraviolet (UV) stabilizer additives

For more available products Shop Desco

ESD Flooring

Products are designed to prevent static electricity from building up as people that are wearing foot grounders work and move about the environment. They include flooring products such as rolled matting, floor finish, cleaners, and rubber tiles.

Cleans conductive/dissipative floor tile, paint, latex, floor finish and other ESD flooring substrates.

Cleans conductive/dissipative floor tile, paint, latex, floor finish and other ESD flooring substrates.

Does not contain silicone or other insulative substances: standard cleaners with silicone or other insulative substances may leave residue which inhibits the performance of ESD flooring.

Does not contain silicone or other insulative substances: standard cleaners with silicone or other insulative substances may leave residue which inhibits the performance of ESD flooring.

Bag-in-box packaging available

Bag-in-box packaging available

For more available products Statguard Flooring

ESD Test Equipment

ESD test equipment is used to verify that the ESD control devices in use are functioning correctly. These devices include ESD event meters, data acquisition systems, continuous monitors, personnel grounding testers, static field meter, ionization test kit, and surface resistance meters.

Single workstation continuous monitor: meets ANSI/ESD S20.20 in accordance with ESD TR1.0-01-01

Single workstation continuous monitor: meets ANSI/ESD S20.20 in accordance with ESD TR1.0-01-01

Continuously monitors 2 operator dual-wire wrist straps and 1 work surface mat. Visible and audible alarms indicate improper grounding of the operator and work surface.

Continuously monitors 2 operator dual-wire wrist straps and 1 work surface mat. Visible and audible alarms indicate improper grounding of the operator and work surface.

Adjustable operator test voltage and upper limit. Test voltage can be set to 9 or 16 volts; test limit can be set to 10 or 35 megohms.

Adjustable operator test voltage and upper limit. Test voltage can be set to 9 or 16 volts; test limit can be set to 10 or 35 megohms.

Adjustable audible alarm, buzzer volume may be disabled or set to loud or soft.

Adjustable audible alarm, buzzer volume may be disabled or set to loud or soft.

UL safety certified. Complies UL category code number NYOK

UL safety certified. Complies UL category code number NYOK

NIST calibrated with certificate included

NIST calibrated with certificate included

For more available products Shop SCS

ESD Brushes

ESD brushes are used to remove dust, dirt, and other leftover materials from PCBs and other static sensitive components. The brushes are designed to minimize charge generation and remove electrostatic charges when held by a grounded user.

Allows thorough cleaning of ESD sensitive assemblies without the danger of high charges generated by conventional brushes when held by grounded personnel

Allows thorough cleaning of ESD sensitive assemblies without the danger of high charges generated by conventional brushes when held by grounded personnel

Conductive carbon loaded polypropylene handle

Conductive carbon loaded polypropylene handle

ESD properties of conductive handles are not affected by humidity as are wooden handle brushes

ESD properties of conductive handles are not affected by humidity as are wooden handle brushes

Conductive bristles made of black soft carbon nylon

Conductive bristles made of black soft carbon nylon

Firm bristles are mainly for electronics, especially on circuit boards used for removing solder and/or rework debris

Firm bristles are mainly for electronics, especially on circuit boards used for removing solder and/or rework debris

Rtt resistance: 1 x103 to <1 x105 ohms

Rtt resistance: 1 x103 to <1 x105 ohms

For more available products Shop Menda

Ionization Products

Ionization products neutralize charges on insulators preventing induction and charged device model defects to static sensitive devices. Ionizers come in several designs, such as overhead, benchtop, and compressed air.

Point-of-use compressed air ionizer. Neutralize electrostatic charges to eliminate Electrostatic Attraction (ESA), visual imperfections, and contamination by dislodging charged dust and debris

Point-of-use compressed air ionizer. Neutralize electrostatic charges to eliminate Electrostatic Attraction (ESA), visual imperfections, and contamination by dislodging charged dust and debris

Fast < 1 second discharge times with ±30 volt offset voltage balance tested per ANSI/ESD STM 3.1 and ESD TR53. Meets ANSI/ESD S20.20 ionizer required limits

Fast < 1 second discharge times with ±30 volt offset voltage balance tested per ANSI/ESD STM 3.1 and ESD TR53. Meets ANSI/ESD S20.20 ionizer required limits

Modular design with 7 foot ESD protective hose with trigger switch. Allows operators freedom of motion and minimizes awkward or unsupported positions

Modular design with 7 foot ESD protective hose with trigger switch. Allows operators freedom of motion and minimizes awkward or unsupported positions

Use filtered air or nitrogen – no adjustment required. Allows for quick change between compressed gas supply

Use filtered air or nitrogen – no adjustment required. Allows for quick change between compressed gas supply

NIST calibrated with certificate included

NIST calibrated with certificate included

For more available products Shop SCS

Garments

Garments are designed to shield static sensitive devices from static electricity that may build up on a person’s clothing.

Groundable static control garment system tested per ANSI/ESD S20.20-2014 (Rtg < 3.5 X 107 ohms) requirements, per ANSI/ESD STM2.1. Allows operators and smock to be bonded or electrically connected to ground to prevent ESD events in ESD protected areas.

Groundable static control garment system tested per ANSI/ESD S20.20-2014 (Rtg < 3.5 X 107 ohms) requirements, per ANSI/ESD STM2.1. Allows operators and smock to be bonded or electrically connected to ground to prevent ESD events in ESD protected areas.

Minimum of 9% carbon conductive nylon fibers woven in Chain-Link Design. Provides continuous and consistent charge dissipation throughout lifetime of smock.

Minimum of 9% carbon conductive nylon fibers woven in Chain-Link Design. Provides continuous and consistent charge dissipation throughout lifetime of smock.

Creates Faraday Cage Effect around torso and arms of operator. Shields ESD charges on operators' clothing from damaging ESD sensitive items.

Creates Faraday Cage Effect around torso and arms of operator. Shields ESD charges on operators' clothing from damaging ESD sensitive items.

Panel-to-panel conductivity. Prevents isolated charged conductor in ESD protected area.

Panel-to-panel conductivity. Prevents isolated charged conductor in ESD protected area.

Hip-to-cuff grounding. Grounds operator with no need for a cord to be attached to the operator's wrist.

Hip-to-cuff grounding. Grounds operator with no need for a cord to be attached to the operator's wrist.

For more available products Shop Desco

American National Standards Institute (ANSI): a non-profit organization that coordinates the development of voluntary standards for several industries in the U.S.

American National Standards Institute (ANSI): a non-profit organization that coordinates the development of voluntary standards for several industries in the U.S.

Charged Device Model (CDM): a test model that simulates an ESD when a component comes into contact with a conductive material or electric field, such as in a manufacturing environment, and is charged either directly or indirectly.

Charged Device Model (CDM): a test model that simulates an ESD when a component comes into contact with a conductive material or electric field, such as in a manufacturing environment, and is charged either directly or indirectly.

Electrostatic Discharge (ESD): the rapid, sudden flow of electrostatic charge that occurs when two objects come into contact or close proximity with each other.

Electrostatic Discharge (ESD): the rapid, sudden flow of electrostatic charge that occurs when two objects come into contact or close proximity with each other.

Electrostatic Induction: the induction of an electrical charge in a material when brought into proximity with another charged object.

Electrostatic Induction: the induction of an electrical charge in a material when brought into proximity with another charged object.

Electrostatic Protected Area (EPA): a designated area where all surfaces, people, objects, and ESDS devices are kept at the same electrical potential.

Electrostatic Protected Area (EPA): a designated area where all surfaces, people, objects, and ESDS devices are kept at the same electrical potential.

ESD Susceptible or Sensitive (ESDS): components or devices that are easily affected or damaged by even small amounts of ESD.

ESD Susceptible or Sensitive (ESDS): components or devices that are easily affected or damaged by even small amounts of ESD.

Human Body Model (HBM): a test model that simulates how a component might be affected when an ESD generated by a human contact occurs.

Human Body Model (HBM): a test model that simulates how a component might be affected when an ESD generated by a human contact occurs.

Machine Model (MM): a test model designed to simulate an ESD from equipment, such as electrical devices, components, or empty sockets, to the component being tested.

Machine Model (MM): a test model designed to simulate an ESD from equipment, such as electrical devices, components, or empty sockets, to the component being tested.

Metal Oxide Semiconductor (MOS): a structure for creating electronic components, like transistors, where the insulator layer is typically an oxide of the substrate layer.

Metal Oxide Semiconductor (MOS): a structure for creating electronic components, like transistors, where the insulator layer is typically an oxide of the substrate layer.

Static Electricity: a charge caused by the imbalance between negative and positive charges on the surface of or within an object.

Static Electricity: a charge caused by the imbalance between negative and positive charges on the surface of or within an object.

Triboelectric Charging: a type of electrical charging where materials become charged after coming into contact and then being separated from a different material.

Triboelectric Charging: a type of electrical charging where materials become charged after coming into contact and then being separated from a different material.

*Trademark. Desco Industries is a trademark of Desco Industries Inc. Other logos, product and/or company names may be trademarks of their respective owners.

Test Your KnowledgeBack to Top

Are you ready to demonstrate your knowledge of Electrostatic Discharge and Prevention? Then take a quick 10-question quiz to see how much you've learned. To earn the Static Control I Badge, read through the learning module, attain 100% on the Quiz, leave us some feedback in the comments section, and give the learning module a star rating.

Top Comments