Earlier this holiday, I repaired my turntable. It's an odd-one-out model from the earlier 60's and uses a particular mechanism to regulate speed: an eddy current break.

The whole setup is out of the usual: the turntable platter is very heavy - 3.63 Kg (8 lb). It acts as a flywheel. It's powered by a weak motor that spins a little too fast. Then there's a magnetic break that wicks the speed a little down until the desired speed.

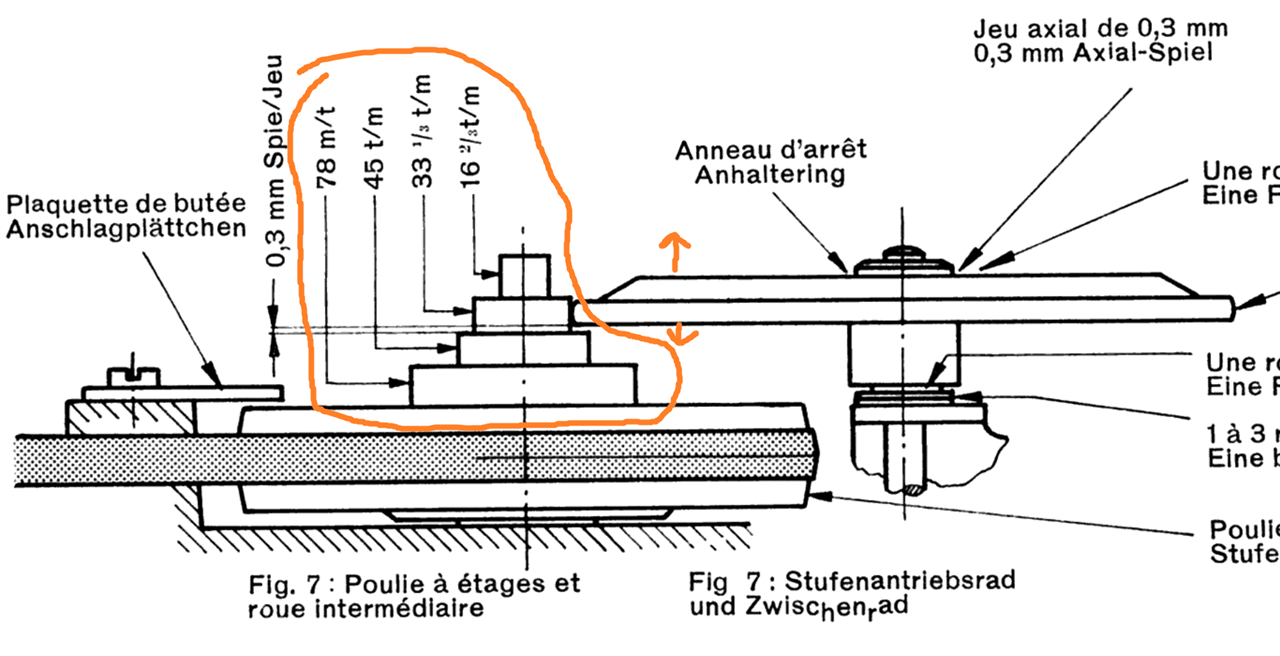

image source: vinylengine.com - although it's a scan of a Thorens manual, edited by me. fair use.

On the left side, you see the motor pully. That runs a little too fast. A rubber belt transfers the rotation to a tapered speed wheel.

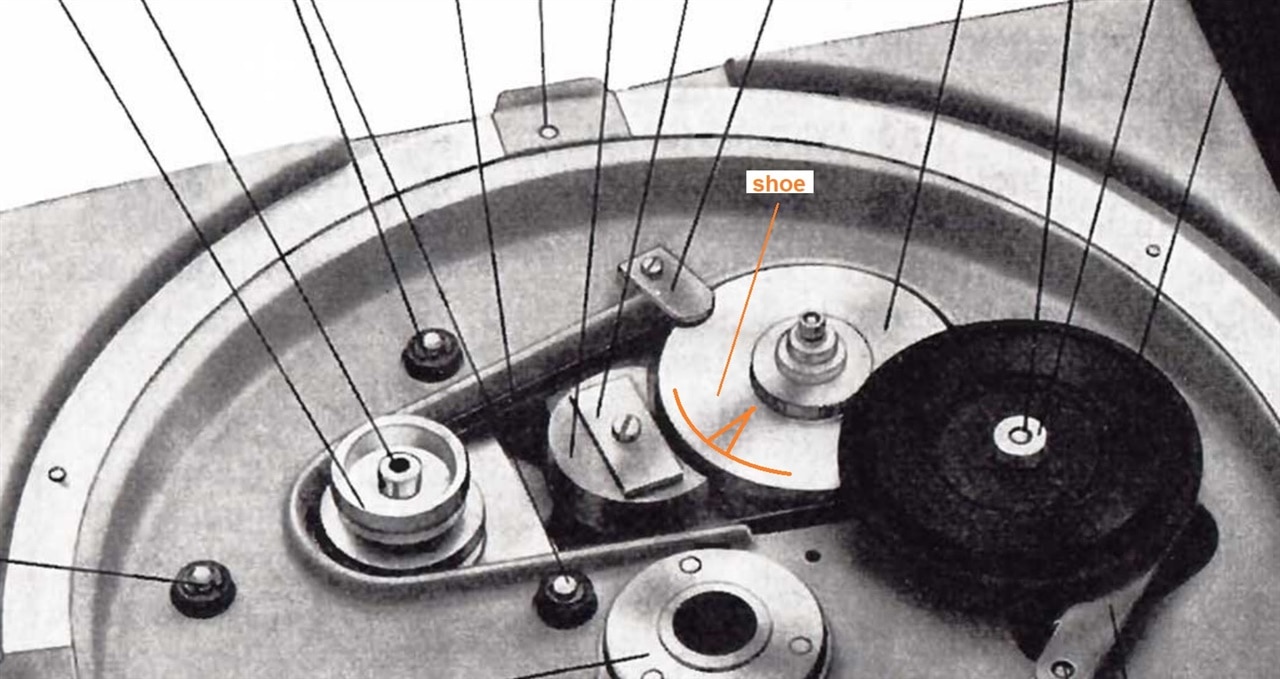

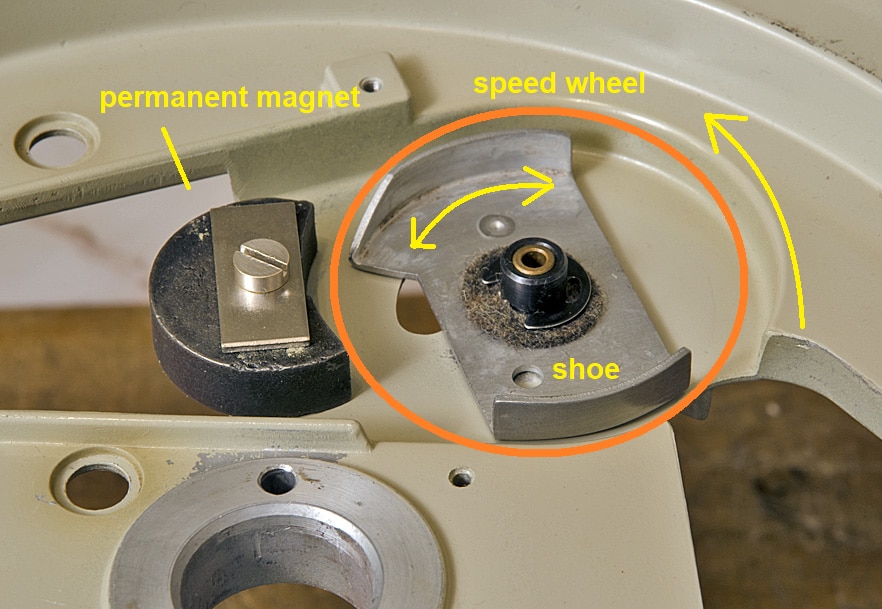

That wheel is controlled by the eddy break. On the left side of that wheel, a permanent magnet is attached. By itself, it has little effect on the rotation of the speed wheel. Inside that wheel (it's hollow), sits a shoe that can be turned in front of the magnet or away from it. You can't see that part on the photo above, because the speed wheel sits on top of it. I drew it in orange. By moving more of the shoe in front of the magnet, you increase the breaking effect. The eddy current that's created by the speed wheel rotating in between, causes that. The photo below shows the mechanism with the speed wheel removed.

image source: diyAudio annotated by me - fair use

The result is that when you move the shoe out of the way, the table will run too fast. You then move the shoe in bit-by-bit by turning a knob, until the speed is correct.