Can you have enough stepper motors? Maybe.

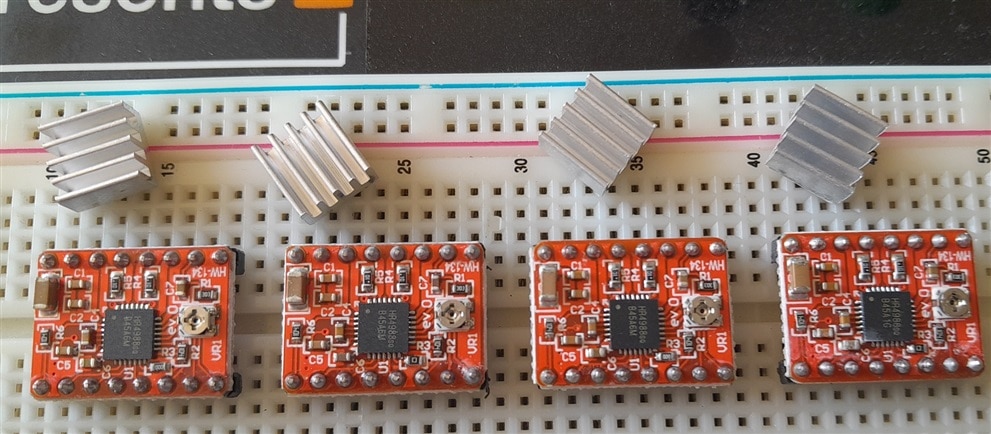

I did an investment. I had one driver IC and a good motor. I added 4 somewhat heavier motors, and 4 Allegro A4988 drivers.

(for my own documentation)

- Motor Type: Bipolar Stepper

- Step Angle: 1.8 deg.

- Holding Torque: 40N.cm (56oz.in)

- Rated Current/phase: 1.7A

- Phase Resistance: 1.5Ohm±10%

- Insulation Resistance: 100MΩ¸ Min, 500VDC

- Insulation Strength: 500VAC for one minute

- Physical Specification:

- Frame Size: 42 x 42mm (1.7 inch x 1.7 inch)

- Body Length: 40mm

- Shaft Diameter: 5mm

- Number of Wire Leads: 4

- Wire Length: 400mm

- Weight: 280g

- Temperature rise: 80deg Max(rated current, 2 phase on)

Rood B+

Groen A-

Zwart A+

Blauw B-

One more strange stepper is on its way from China: ,

,

Goal is to control them with a single Pico.