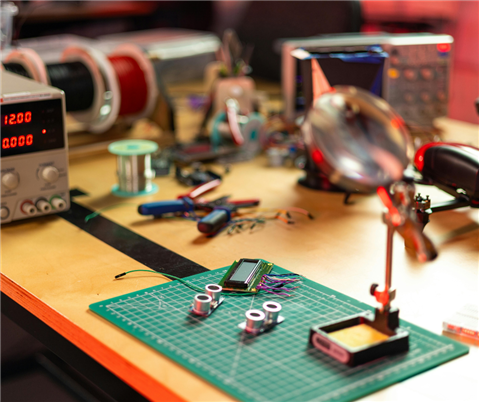

Shout out to all engineers, makers, and design enthusiasts!

Last month, we asked you about your project disaster What was your biggest project Disaster? We are asking e14 in our Join, Share & Win Competition

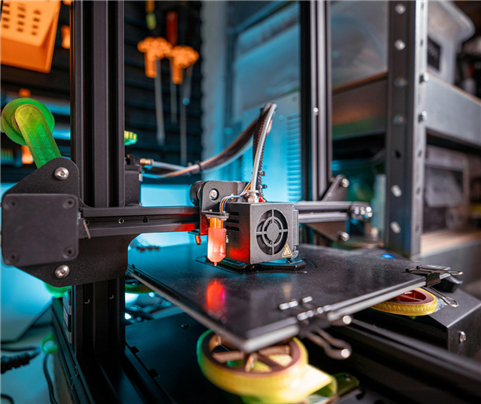

This month, we want to know if you could automate one part of your design workflow. What would it be?

Competition

Join the element14 Community today and take part in our latest “Join, Share & Win” challenge.

It’s simple:

1. Register (or Login) for FREE

2. Answer this question by adding a reply / commenting:

If you could automate one part of your design workflow, what would it be?

3. Be in with a chance to WIN!

Share with us your best (hopefully lighthearted) watercooler story of a design workflow that, if automated, would genuinely change your game.

The Community Judge team will select our 3 favourite answers to win one of the prizes below.

Here’s what you could win:

Please congratulate:

E14Alice will be reaching out to you all to get your prizes sorted via direct message

General Terms

What: Win 1 of 3 of the RPI5-4GB-SINGLE Raspberry Pi5

How: Sign up or Sign in and Comment your answer to If you could automate one part of your design workflow, what would it be?

When: Before November 30th 2025

Anything else: Full terms are below, but we must be able to ship to the address in your account.

Entries close November 30th, 2025, so don’t wait!

Terms & Conditions