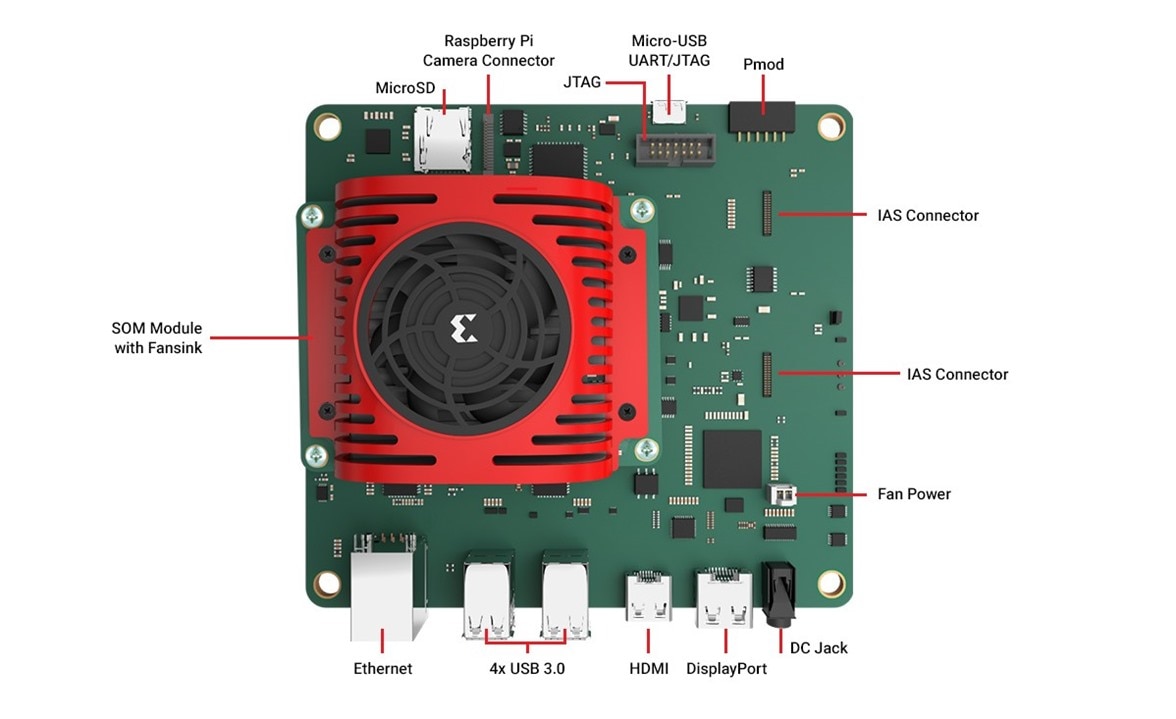

AMD-Xilinx (gonna take me a while to get used to that name) released their own system on module (SOM) solution with the introduction of the Kria K26 family. These were originally released along with vision AI starter kit to help developers get started with designs around this product. https://www.newark.com/xilinx/sm-k26-xcl2gc/system-on-module-zynq-ultrascale/dp/50AJ6081

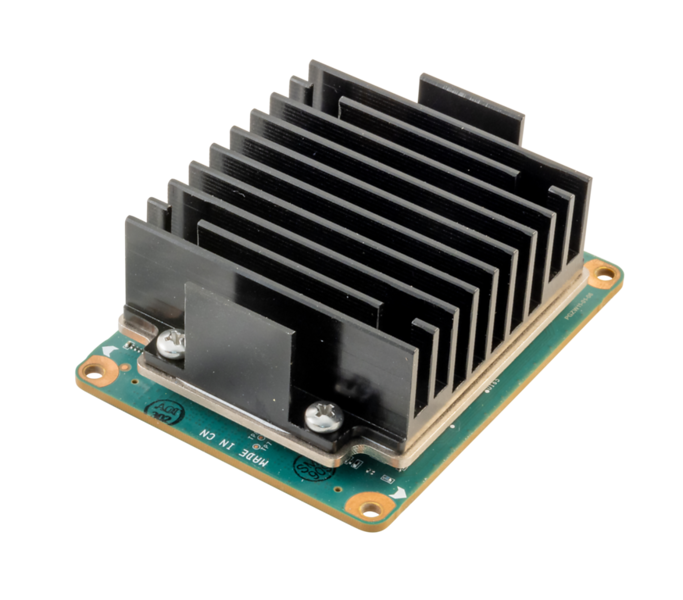

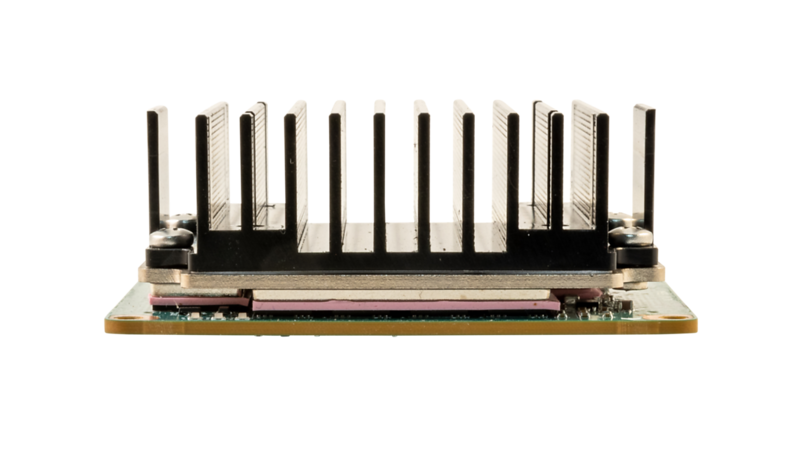

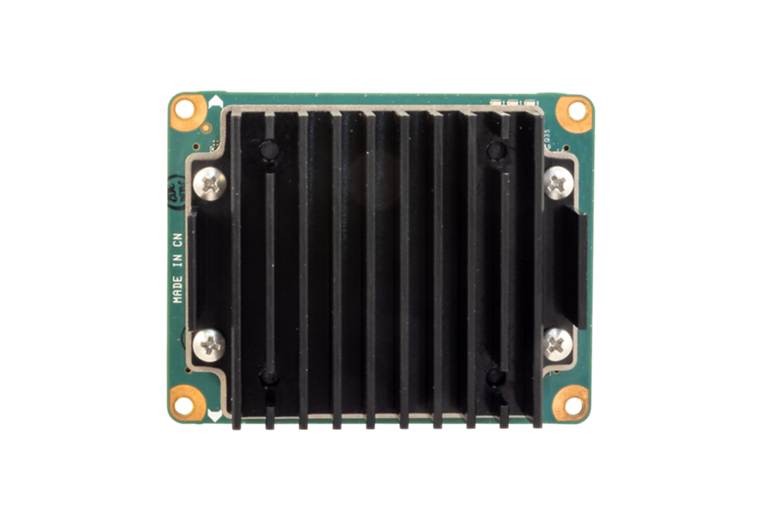

Below are pictures of the starter kit SOM and carrier, along with the production SOM... notice any glaring differences?

While the starter kit includes a carrier and integrated fansink, the stand alone SOM ships with no thermal solution outside of a dedicated heat spreader plate. Customers must design their own thermal solution for cooling the SOM in their own product environments. While this gives customers design freedom, it also introduces an imperative design responsibility. The SOM is not designed to operate without a thermal relief solution, doing so will most likely result in failure. Knowing these things I worked directly with AMD-Xilinx to design a thermal solution optimized for the Kria K26 platform.

https://www.avnet.com/wps/portal/us/products/avnet-boards/related-parts/avnet-heat-sink-for-kria-26/

This design was created for specific purposes. One was the ability to run low power (8.5W or less) designs in a room temperature environment without the need for a fan. Ask any of your software developers or even hardware guys working on your product how much they love that constant fan noise on their desk. Beyond just the audible annoyance, mechanical fans obviously introduce more power consumption as well as physical wear components. Don't get me wrong, in many applications fans are a necessary evil, but if you are working on a 5W design in your lab, do you REALLY need to listen to that turbine nonstop? Not with this solution you don't.

Again the idea here is a modular solution. So while this heat sink has been designed to provide passive relief at room temperature up to 8.5W, I also included mounting holes to attach a standard 50x50mm fan to the top of the solution. Adding this fan dramatically lowers the thermal impedance allowing for much higher power designs as well as a much higher operating environment.

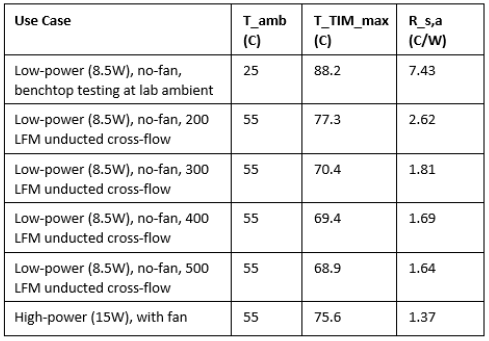

This table is included in the datasheet for the heat sink and gives some thermal impedance numbers passively as well as with various levels of airflow:

Now to be clear, to get final numbers analysis must be done in your system. The point this table makes though is that you have avenues using the base passive solution to dramatically reduce the thermal impedance by adding a fan. By not design limiting your options on the fan, you are free to use whatever fan you choose. That flexibility allows you to use whatever voltage, speed and control method you choose. Using a standard footprint gives you a ton of freedom on your fan selection.

Avnet has the ability to offer assistance in designing custom thermal solutions for your products as well. Reach out today if you have an application that could use some assistance. We can recommend off the shelf, semi-custom or full custom options. - https://engage.avnet.com/thermal