Hi all, in this post i am going to upload my final project. I have been able to design a doctor assistant kit using LabVIEW but with few shortcomings.

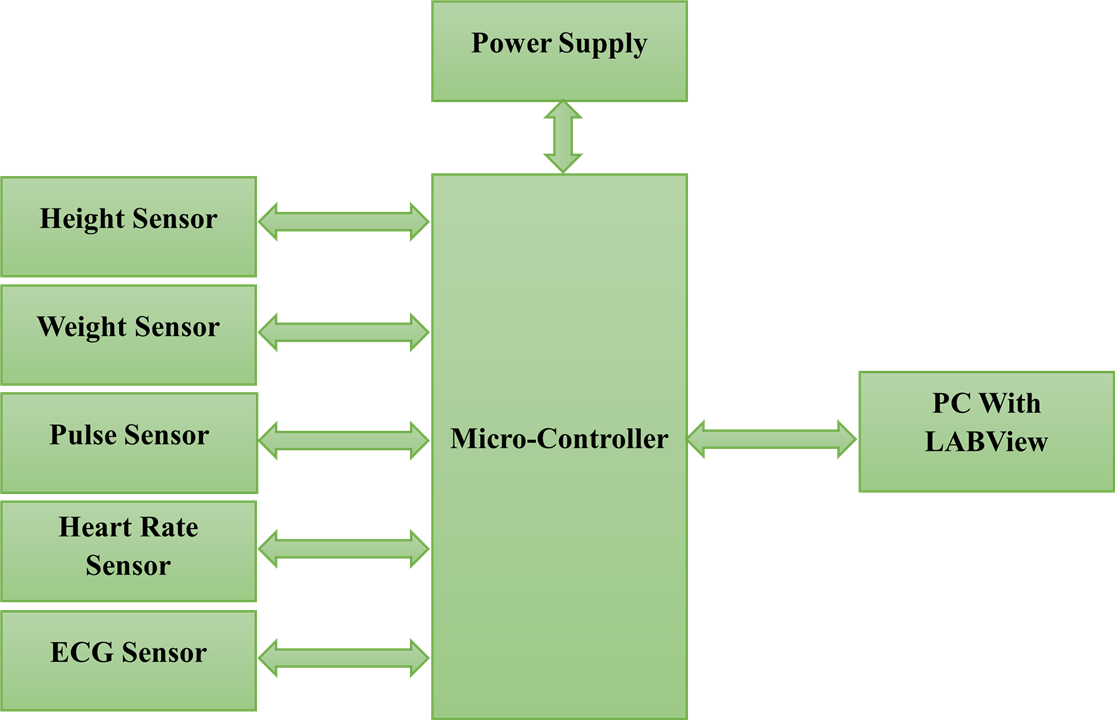

Fig below shows the block diagram of my project.

As shown in the block diagram above, various sensors have been used for detecting various bioelectric signals which are acquired using microcontroller(ARDUINO/PICO PI) and integrated using LabVIEW.

Ultrasound sensor has been used for measuring height which was successfully displayed on LabView front panel. 50 KG x 4 load cells have been used in differential manner to measure body weight.

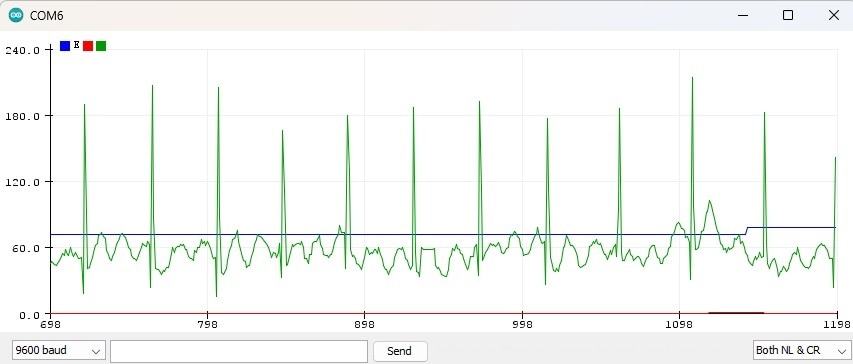

MLX90614 non contact infrared sensor has been used for measuring human body temperature and results were obtained on LabVIEW GUI. AD8232 Heart rate monitoring sensor has been used for measuring ECG and heart rate variability( RR interval). ECG waveform was observed on serial plotter but i was unable to display the same on GUI in LabVIEW. I am working on rectifying the issues which may possibly be because of the baud rate as i am trying to acquire data from multiple sensors simultaneously.

MAX30102 PULSE OXIMETER sensor has been used for measuring SpO2 levels. I2C protocol has been used while acquiring data . Results were successfully obtained on the LabVIEW GUI.

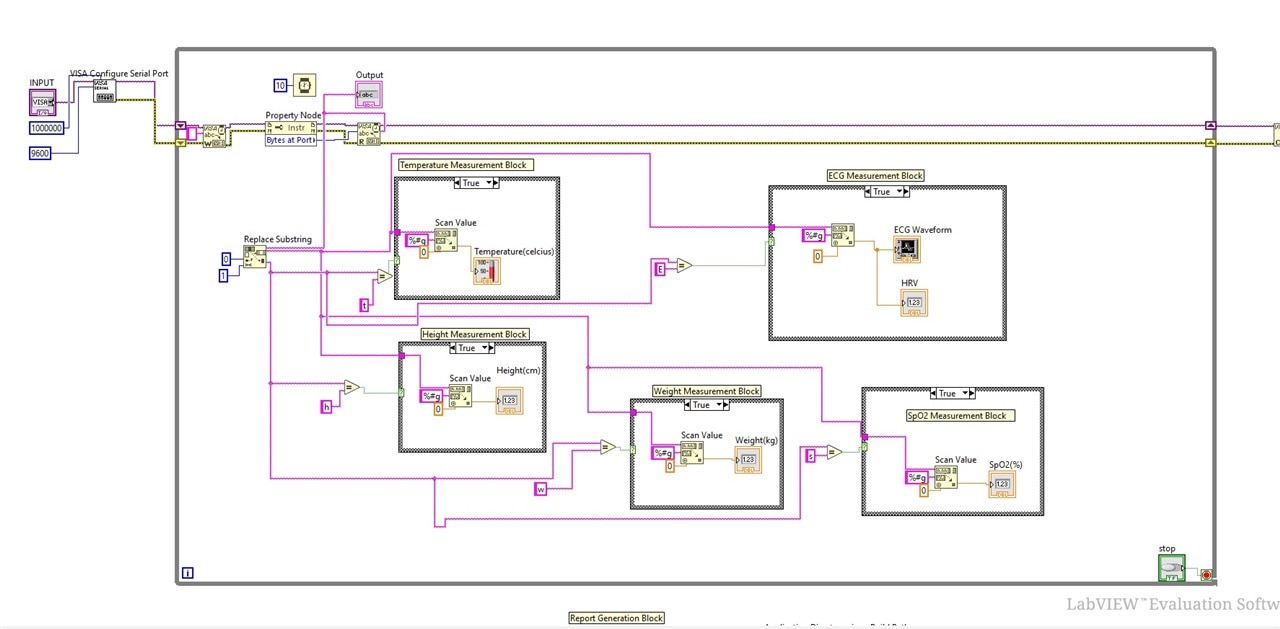

Front Panel and Block diagram of the project designed in LabVIEW are shown below:

The block diagram shown above highlights various sections for different sensor data acquisition. Temperature measurement unit, Height measurement unit, ECG Measurement unit, Report generation section, weight measurement unit and SpO2 unit work simultaneously based on string append against their values. Various blocks and icons used in the block diagram are kept with their labels for easy understanding.

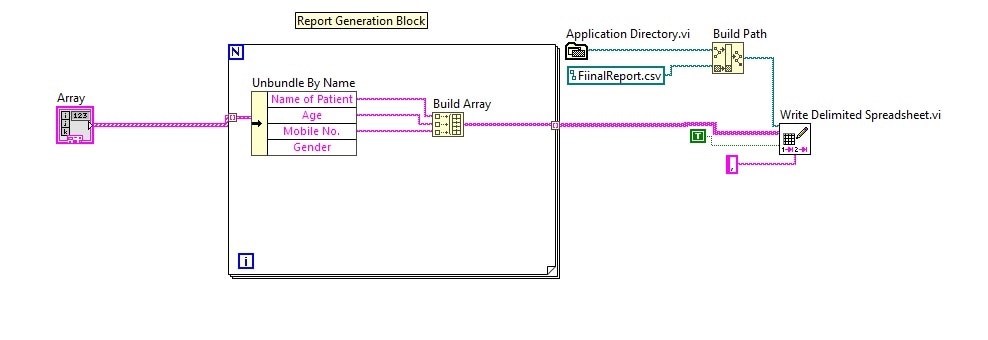

Report generation section consisting of Name, Age, Gender, etc. in the block diagram is shown below

The report generation block thus far includes direct entry parameters such as name, age, gender, mobile number. Various sensor data values are yet to be incorporated in the final report.

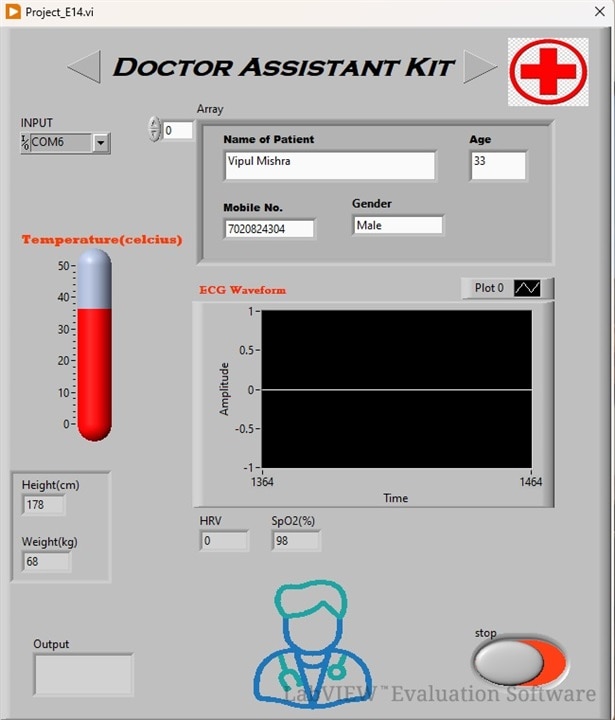

Front Panel of designed Doctor Assistant Kit is shown below:

As discussed earlier, ECG waveform was not obtained on the front panel for the said reasons, though it is observed on serial plotter as shown below:

The complete experimental unit is yet to be assembled in a proper kit though certain images taken during experimentation are attached below.

As observed from the post, final packaged assembly with a fixed setup is yet to be designed. I am working on further reducing the vulnerabilities of the Block Diagram designed in LabVIEW. It has been a learning journey thus far and i am expecting to finish this sooner than later.

Thanks and cheers to Element 14 and National Instruments for giving me an opportunity to learn various insights of LabVIEW.