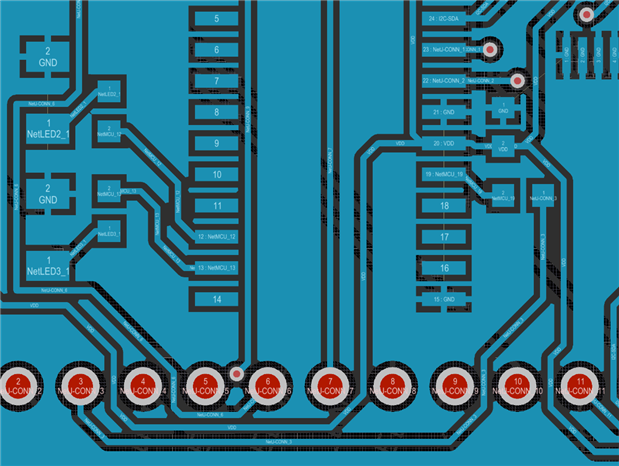

In my PCB layout, part of which is shown below, I have a copper pour serving as a ground plane. A problem that I didn't catch with this design before having it fabricated is that a couple of regions of copper pour are not actually connected to the GND net at all. Below, the pour that pads 15 and 21 are connected to, both GND pads for an MCU, is not at all connected to the GND net. Same for the region that includes the GND pad above the 1 "NetLED3_1" pad on the far right. I use the Autoroute tool to do pretty much all of the routing. Once the auto-routing is done, the polygon/copper pour gets re-poured.

So, my question is: how can I ensure that GND plane regions, which may not be contiguous with the GND plane region that is in the GND net, does get connected to the GND net with a via or something else?

I taught myself PCB layout and still have a lot to learn, so any education is welcome. Thanks!