Hi Andy -

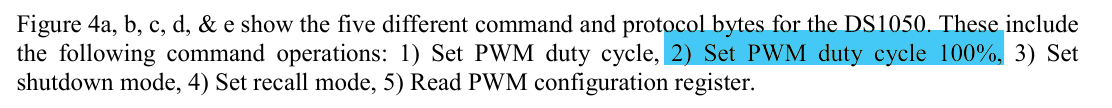

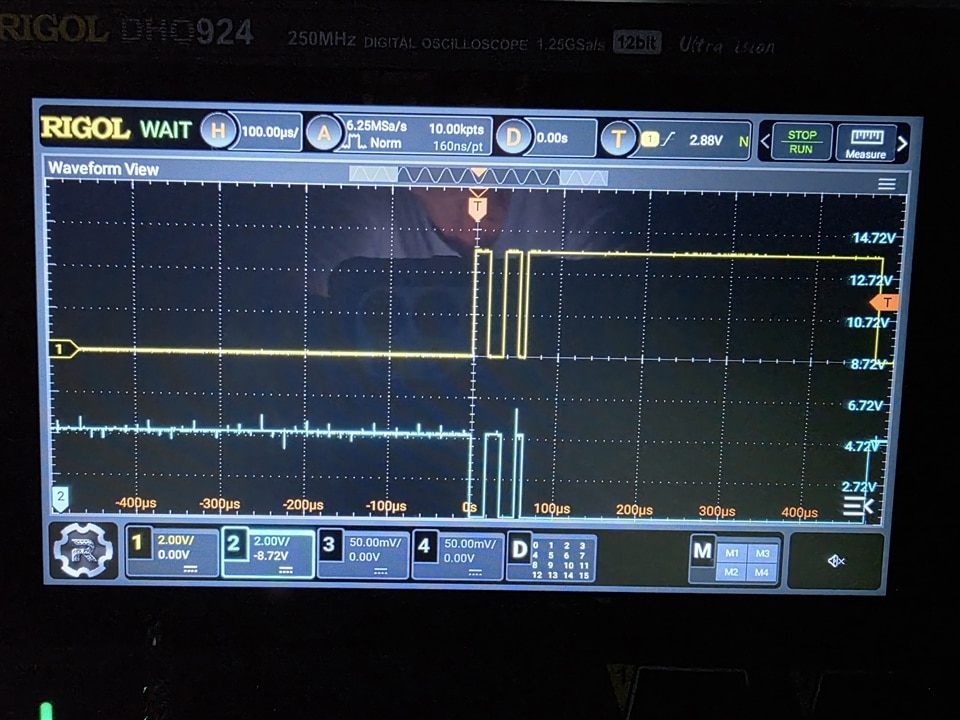

I had my DS1050-025 running, for a while, but now I can only get about 3 to 10 cycles out it. I have gone back over changes I have made, but nothing seems to help. Here is the test code I am currently trying. I open the DS1050 i2c, using address 0x28 ( as shown by i2cdetect on my Raspberry Pi, which this hardware is on). Then I write 0x50 (set PMW command) followed by the data (shown as 0x10h - which should be 50% PWM).

I close the file descriptor, call the second function, where I open the DS1050 in i2c again, writing 0x50 (set PWM command) followed by the data 0x20 as shown on the DS1050 data sheet. Then again close the file descriptor. I have tried combining the two functions and write 0x50, 0x10, 0x50, 0x20 and the close i2c with the same results.

#include <stdio.h>

#include <stdlib.h>

#include <math.h>

#include "/home/dvf/glg/include/GlgApi.h"

#include <sys/types.h>

#include <sys/stat.h>

#include <fcntl.h>

#include <unistd.h> // read/write usleep

#include <inttypes.h> // uint8_t, etc

#include <linux/i2c-dev.h> // I2C bus definitions

#include <sys/ioctl.h> //Needed for I2C port

#include "/home/dvf/glg/include/GlgApi.h"

#include <sys/socket.h>

#include <netinet/in.h>

#include <string.h>

#include <arpa/inet.h>

#include <termios.h>

#include <stdio.h>

#include <sys/types.h> // open

#include <sys/stat.h> // open

#include <fcntl.h> // open

#include <unistd.h> // read/write usleep

#include <stdlib.h> // exit

#include <inttypes.h> // uint8_t, etc

#include <linux/i2c-dev.h> // I2C bus definitions

#include <sys/ioctl.h>

#include "PWM.h"

int PWM_Write2(void);

int fd_pwm, fd;

int16_t val;

uint8_t writeBuf[5], readBuf[2];

void main(void)

{

// open device on /dev/i2c-1

if ((fd_pwm = open("/dev/i2c-1", O_RDWR)) < 0)

{

printf("Error: Couldn't open I2C device\n");

return;

}

// connect to ads1115 as i2c slave

if (ioctl(fd_pwm, I2C_SLAVE, PWM_Addrs) < 0)

{

printf("Error: Couldn't find device on address!\n");

return;

}

// set config register and start conversion

writeBuf[0] = SetPWM; // config register is 1

writeBuf[1] = 0x10;

// Set newm PWM duty

if (write(fd_pwm, writeBuf, 4) != 4)

{

printf("Can't write to register 1\n");

return;

}

close(fd_pwm);

PWM_Write2();

while(1)

{

;

}

}

int PWM_Write2(void)

{

// open device on /dev/i2c-1

if ((fd = open("/dev/i2c-1", O_RDWR)) < 0) {

printf("Error: Couldn't open I2C device\n");

return 1;

}

printf("fd = %d\n",fd);

// connect to ads1115 as i2c slave

if (ioctl(fd, I2C_SLAVE, PWM_Addrs) < 0) {

printf("Error: Couldn't find device on address!\n");

return 1;

}

// set config register and start conversion

writeBuf[0] = SetPWM; // config register is 1

writeBuf[1] = 0x20;

// Set newm PWM duty

if (write(fd, writeBuf, 2) != 2)

{

printf("Can't write to register 1\n");

return 1;

}

close(fd);

}

Hope you can help,

David

YouTube "Sailing Solo at 70"