Overview

Choosing the right technology for your design validation testing, automated system testing, and mechanical test pays off in time to market and total cost of test. Here are seven reasons CompactDAQ should be one of those technologies.

Flexible Hardware

Your products change. Even when they don’t, customers are going to ask you to test something “off the menu.” How easy is it to add a power measurement to validate battery life, add more thermocouples to track component heat production, or upgrade to high-speed inputs to catch operating state transitions? Build your test system on CompactDAQ and use any of the more than 100 measurement modules to meet your test requirements now and in the future.

FIGURE 1. Use the over 100 modules for CompactDAQ to meet your sensor and signal requirements now, and in the future when they change.

Flexible Software

The best software in the world doesn’t matter if your team can’t use it. NI has one of the best selections of software support on the market. Choose to develop with LabVIEW, Python, MathWorks MATLAB® software, C, C+, C#, VB 6.0, .NET, or choose not to program at all and use NI’s FlexLogger configuration-based data acquisition software. Want more choice? Call DLLs or scripts from LabVIEW. Use Python scripts to automate FlexLogger projects. Reuse your existing code and adjust the software to your team, instead of having to adjust your team to the software.

FIGURE 2. Choosing the right software tool becomes less of an issue because you can integrate your existing code for analysis, communication, or data formatting into LabVIEW.

Synchronization

Things happen fast on complex designs. What is the pressure difference as the valve opens to 50 percent? What is the flow rate when the pump is at 60 RPM? What is the current draw on the motor at maximum torque? You need synchronized measurements. CompactDAQ chassis with Time Sensitive Networking (TSN) technology synchronize all measurement modules in the chassis and between connected chassis, so test and design teams can link cause to effect, faster.

FIGURE 3. CompactDAQ chassis with TSN synchronization use the Ethernet cable for communication and synchronization. Run test software from a connected PC, or from a CompactRIO system with DAQmx compatibility (as seen in image)

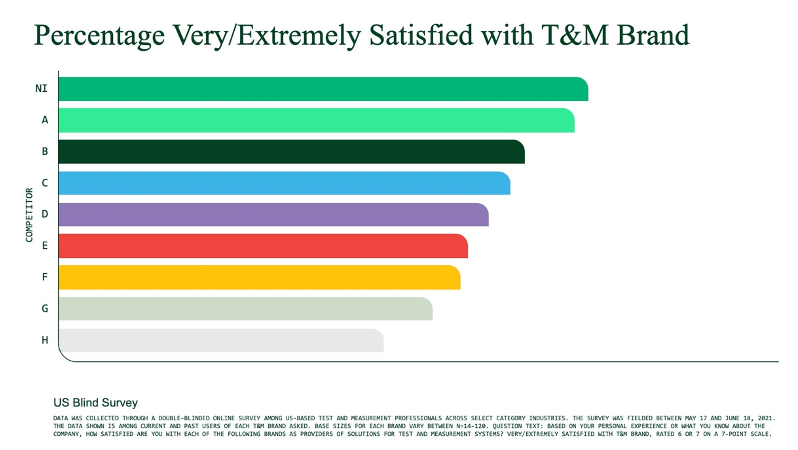

A Brand Known for Reliability

Datasheets don’t mean much without brand quality. Have confidence you’ll get the data you need when you need it. NI instrumentation is built with more than 40 years of experience in test and measurement so you can Engineer Ambitiously.

FIGURE 4. NI has worked with test engineers for decades and blind surveys show our brand is associated with overall satisfaction.

Automation for System Testing

Life-cycle tests, battery drain tests, repetitive system tests: these should happen while you’re at lunch or overnight while you’re sleeping. Automate them! Use analog and digital output modules to modify controller setpoints or simply turn things off and on. Using a PLC for some of this today? Pick a chassis with a built-in controller that runs a Linux-based RTOS so you can add an extra layer of reliability.

FIGURE 5. Use CompactDAQ’ s flexible software options and hardware output channels to build a fully automated test system for tests such as temperature ramp-and-soak in thermal chambers as seen in the image above.

Ruggedness

Functional testing environments aren’t always clean, air-conditioned spaces. Be confident your test system will survive real-world conditions with -40 to 70 ºC, 50 g shock, and 5 g vibration operating specifications.

FIGURE 6. Rugged shock, vibration, and temperature specs let you install CompactDAQ close to your DUT for shorter signal wires and a faster setup experience.

Size/Portability

Take CompactDAQ hardware with you so you have the data you need to make decisions. Use the 1-slot USB-powered chassis with a laptop for walk-around measurements and test your designs on the proving grounds or your real-life test bed. Build a Pelican-case style system and take it to a customer installation to see what they see—or just ship it to them. Either way, shorten the back-and-forth and focus on engineering a fix. This is portability without sacrificing capability: a 256-channel system fits into a space the size of a small suitcase.

FIGURE 7. Build CompactDAQ into a portable case to validate systems on site with customers or in real-world testbeds.

Next Steps

Save time building your next test system with the Design Validation Test System Build Guide for CompactDAQ

MATLAB® is a registered trademark of The MathWorks, Inc. Other product and company names listed are trademarks or trade names of their respective companies.