This blog first appeared on the Tektronix website

Introduction

In PCB validation and manufacturing workflows there is an increasing need for cost reduction, effectual defect detection, repeatability, improved throughput and minimized touch time. Many of Tektronix’ customers are utilizing, or planning to utilize, an automated testing solution to address these needs.

The costs of capturing defects and addressing manufacturing or design gaps downstream of final assembly are substantial. Flying probe automated test equipment (ATE) technologies have become a global front-runner in PCB test for their flexibility, speed, accuracy and automation capability.

At Tektronix we are committed in assisting our customers along their test and validation journeys. To this end, we’re excited to announce the release of our TAP1500L; a 1.5 GHz single-ended, low-capacitance active probe that was designed with a 7 meter cable – aimed directly at our ATE development customers, end-users, or any engineer who desires greater distance between their test stations and DUTs. With the industry’s longest cable length for an active oscilloscope probe, the TAP1500L does not compromise performance and provides one additional meter versus other single-ended active probes in the market.

The TAP1500L requires no external power supply, is compatible with all the accessories within Tektronix’ single-ended active probe catalogue and performs equivalently with our best-selling TAP1500 oscilloscope probe.

Flying Probe Test vs. In-Circuit Test

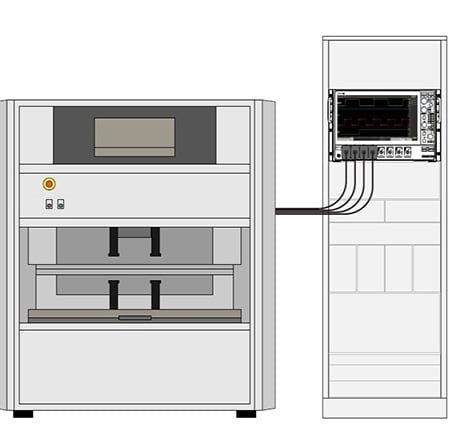

Flying Probe Test (FPT) is an automated process utilizing flying probe testers to assess PCBs in design, validation and manufacturing workflows. Probes, typically attached to robotic arms and aided by high-resolution cameras, swiftly glide over and below the PCB surface automatically making electrical contact at specific test points on the PCB to provide real-time data to engineers. This probing process quickly identifies defects such as open circuits or component placement issues without the need for custom test setups, or bed-of-nails fixtures. FPT can also be used for functional testing, in which a populated board is powered up and running. In this application, single-ended, active oscilloscope probes and an accompanying oscilloscope can be integrated into the system to perform go/no-go testing on critical signals. A key benefit to FPT is changes to PCB layout or design do not require any new fixturing to conduct quality or validation tests. A change in the FPT test program to accommodate the PCB design changes allows for a nimbler approach to PCB testing and increases throughput at this process step.

Tektronix has solved a critical pain point by extending our standard cable length by more than 5 times.

In-Circuit Test (ICT) is a more traditional method of testing PCBs, typically utilizing a bed-of-nails test fixture. Bed-of-Nails relies on a customized fixture unique to the PCB under test and involves some amount of spring-loaded electrical connections to measure circuit behavior during quality control, manufacturing or functional testing procedures. ICT is a valid and effectual method for testing PCBs at various stages in the development and manufacturing process. However, as form factors shrink, PCB designs increase in complexity and aggressive cost savings are pursued, more customers are exploring and implementing FPTs to meet their performance goals.

With FPT, testing with multiple probes moving along 3-axes at high speed requires careful planning and design to minimize damage to the DUT or to the probes themselves. Tektronix has solved a critical pain point by extending our standard cable length by more than 5 times - providing engineers greater flexibility in how they design these ATE systems and how these systems interface with their oscilloscopes and other measurement hardware.

Performance Characteristics

Using our best-selling TAP1500 single-ended active probe as a backbone, Tektronix was successful in increasing the probe cable length with no impact to probe performance. Increasing cable length presents some performance challenges, specifically increased impedance and impacts to rise time and step response. Tektronix was able to solve these performance deltas with a customized DSP (Digital Signal Processor) that accompanies every TAP1500L. A simple installation of this DSP to the appropriate math channel level-sets the TAP1500L performance with the TAP1500 upon which it was developed. No additional power supply is required to utilize the TAP1500L. The TAP1500L is compatible with 4 Series, 5 Series and 6 Series MSO midrange oscilloscopes and utilizes the TekVPITM probe to oscilloscope interface. This enables the engineer to see results and adjust key parameters in real-time from the front panel of the oscilloscope.

| Specification | TAP1500L w/DSP | TAP1500 |

|---|---|---|

|

Cable Length |

7m |

1.3m |

|

Bandwidth |

1.5 GHz |

1.5 GHz |

|

Rise Time |

<267ps |

<267ps |

|

Input Capacitance |

≤1pF |

≤1pF |

|

Input Resistance |

1MΩ |

1MΩ |

|

Input Dynamic Range |

-8V to +8V |

-8V to +8V |

|

DC Input Offset Range |

-10V to +10V |

-10V to +10V |

Table 1: Performance specifications of the TAP1500L vs TAP1500. Even though the cable on the TAP1500L is 7m long, the rise time and input loading are unchanged from the original TAP1500.

Conclusion

The ATE and Flying Probe market spend is expected to increase nearly 3x by 2030, per a 2024 study by Research Reports World, with primary adoption centers forecasted in the Americas, European and Asian regions. Flying probe testing (FPT)is becoming more commonplace in PCB development and probing needs have and will continue to evolve alongside this technology.

Providing probing solutions that address customer pain points is going to be critical as this ATE technology scales to meet global demand. The TAP1500L represents the first step that Tektronix is taking to better partner in this market and empower our customers to make the most out of their FPT investments.