The title says it all. I have a Weller solder station. They have IC reflow gizmos that work together with its hot air gun.

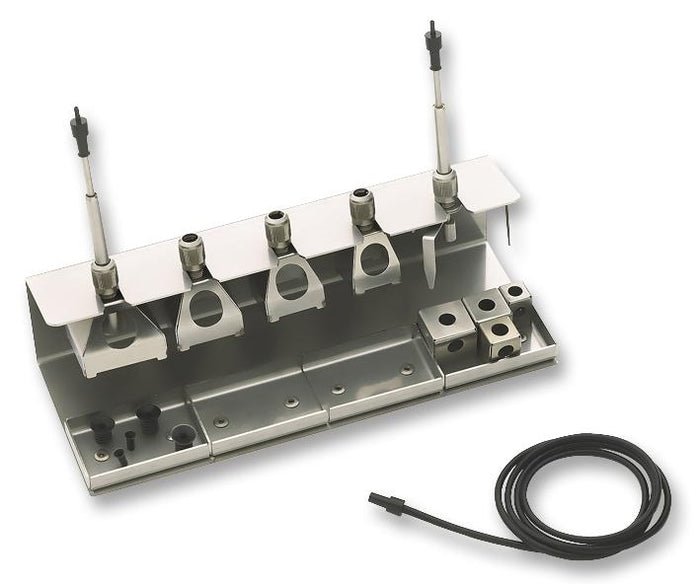

image source: sinuss.nl, the element14 retailer in Belgium and the Netherlands

These are little ovens, that you put on top of the IC you want to rework. Then you put the hot air pencil inside, to flow the solder.

There's a chip lifter (think: coal mine headframe) that can then lift the IC.

It can also be used to place ICs. Should help me with BGA designs.

It may be over-fancy. Paul Daniels and Louis Rossmann do all of this with just a heat gun. But I'm not that skilled - don't do it enough to be repeatedly successful.

My kit is also expensive. The one I bought, with support for 10x10 mm to 33x33 mm (with 6 steps in between), costs 500 €. An amount that I do not easily give away for tools.

Here's a video from Weller:

I have now burned my budget for the next two years (three years actually, but last year I didn't buy anything). It 'd better work as promised.

Send me your old PCBs, so that I can practice.