APPLICATION NOTE

Disinfection with UV-C LEDs

ANO008 BY DOMINIK KOECK

1 Introduction

This application note gives you an overview how disinfection with UV-C light works, the benefits of UV-C LEDs and safety issues that need to be considered when using UV-C LEDs in applications.

Due to the recent COVID-19 pandemic the need for disinfection technologies has skyrocketed. One of these technologies is disinfection using UV-C LEDs. Ultraviolet (UV) light radiation is more energetic than visible light. It is classified by its wavelength into three subgroups:

- UV-A (315-400 nm) Mainly used for material curing applications and horticulture WL-SUMW

- UV-B (280-315 nm) Mainly used for phototherapy and horticulture

- UV-C (100-280 nm) Used for disinfection purposes WL-SUMW

The disinfection capability of UV light has been known since 1877 [1] and already gained great interest in the fight against diseases such as preventing the spread of tuberculosis [4, 5]. In the past, low-pressure mercury-vapor discharge lamps were used for disinfection as they emit at the germicidal wavelength of 254 nm and have relatively large radiant powers. To date, they are often the most economic solution for large scale disinfection.

Figure 1: Würth Elektronik eiSos WL-SUMW UV-C LED with 275 nm wavelength.

The 15335327BA250 LED is suitable for small disinfection targets while the 15335327BA252 product has a higher power for disinfection on a larger scale.

However, UV-C LEDs do have significant advantages. They do not contain hazardous materials such as Mercury (Hg), they do not need long warm up times i.e. they turn on immediately and are suited for frequent on/off switching. Additionally they are not vibration/shock sensitive and are relatively small compared to gas discharge lamps which makes them suitable for a variety of applications.

In recent years, research developed commercially available UV-C emitting LEDs. Even though, the initial UV-C LEDs had lower output, the year 2020 - boosted by the COVID-19 pandemic - has seen a huge increase in radiant power and drop of production price making them a more viable solution for widespread disinfection application.

The following will show the working mechanism of disinfection by UV-C LEDs, discuss the disinfection efficacy at different wavelengths, show an example of disinfection and give a few hints on safety aspects.

2 Work mechanism of UV-C disinfection

2.1 Principle of UV disinfection

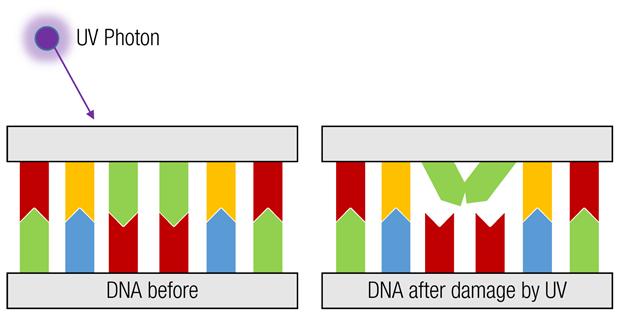

Desinfection with UV-C is based on the fact that UV-C radiation can damage the DNA or RNA. This high energetic UV light can induce formation of pyrimidine dimers [2] and other damages to the DNA which can inhibit multiplication of cells such as bacterial, fungal, plant and animal cells. Similarily the UV light can damage the RNA of viruses leading to their inactivation.

Figure 2: Schematics of DNA damage induced by UV light

2.2 Germicidal wavelengths

Figure 3: Wavelength dependence of RNA damage and radiant flux of Würth Elektronik eiSos LEDs.

In Figure 3, the wavelength dependent RNA damage [3] is shown. The more damage that is done to the RNA, the less capable is the virus of infecting other organisms. It is important to note that for a good sterilization result, a combination of the correct wavelength and a high amount of radiation is required. For the best sterilization result, the wavelength as well as the radiant power need to be considered. As the ratio of the optical power over the electrical power, the Wall-Plug-Efficiency (WPE) is a parameter showing how efficiently the LED can convert electrical power to optical power. The WPE of our standard 275 nm LEDs (PN 15335327BA252), is higher than other UV-C emitting LEDs with shorter wavelength. The optimal wavelength with the best sterilization efficiency will be an LED solution where both the WPE and the wavelength are as ideal as possible. An overview of the combinded sterilization efficiency of some LED solutions available on the market is shown in Figure 4. Here the combined sterilization efficiency is calculated as the product of the corresponding LEDs’ WPE as well as the wavelength-dependent RNA damage. For the investigated LED wavelengths the most efficient solution for disinfection is in fact the 275 nm wavelength LED.

Figure 4: Sterilization efficiency (grey) as the product of RNA Damage (black) and WPE (crosses) is shown in dependence of the wavelength. Compared to other UV-C LED wavelengths available on the market,

a good sterilization efficiency can be achieved with our 275 nm LED.

2.3 Dose

To quantify how well disinfection works, the terminology of log reduction is used. A log reduction of n implies that only 10-n of the previous germs survived. For example, 1 log reduction means that only 10-1 = 10 % of germs survived, i.e. 90 % of germs were inactivated. For 4 log reduction, 10-4 = 0.01 % survive, i.e. 99.99 % were inactivated. To achieve this amount of germ inactivation, a certain amount of UV-C light has to be absorbed by the germs. This amount is called the dose (Irradiance x Exposure time) and is measured in J/m2. For 1 log reduction, the dose D90 is the amount of UV-C light needed to inactivate 90 % of the germs. For 4 log reduction, the dose D99.99 is needed to inactivate 99.99 % of the germs. To estimate the value for the D99.99 dose the D90 dose can simply be multiplied by 4.

| Log reduction | Percentage of germs inactivated | Corresponding dose required |

|---|---|---|

| 1 | 90% | D90 |

| 2 | 99% | D99 |

| 3 | 99.9% | D99.9 |

| 4 | 99.99% | D99.99 |

Table 1: Relation between log reduction, germ inactivation and dose

A number of studies have investigated the D90 dose for viruses, other germs [4] and specifically for the corona virus [5] [6] [7] [8]. Due to different experimental setup this dosage varies widely among the different research groups. To get a usable value, it is possible to get a median value of 37 J/m2 [8], excluding the outliers. Even though these studies where performed with UV-C low pressure lamps we may assume a similar D90 dose for our 275 nm LED. Figure 3 shows that the damage done to the RNA is similar for 275 nm emitted by Würth Elektronik eiSos LEDs and the 254 nm mainly emitted by UV-C low pressure lamps. Additionally some publications, such as [9] show the D90 dose to be quite similar for low-pressure (LP) lamps as for 275 nm LEDs (see following table). An overview of the D90 doses for a few germs is shown in the following table:

| Germ type |

Information on the germ |

D90 Dose ( J / m2 ) |

Lamp type |

|---|---|---|---|

| Virus | |||

| Corona virus [8] |

Corona viruses such as SARS-CoV-2 |

6-117540 Median: 37 |

LP |

| Hepatitis virus [10] | Causes Hepatitis | 40 | LP |

| Influenca [11] |

Responsible for “The Flu” |

20 | LP |

| Adenovirus [12] |

Causes the “Common Cold” |

390 | LP |

| Bacteria | |||

| Salmonella typhimurium [13] |

Can cause food poisoning |

39 | LP |

| Escherichia coli [9] |

Can cause food poisoning |

43 (275nm) -------------- 41 (254nm) |

LED ------------- LP |

| Legionella pneumophila [14] |

Can form in water supplies |

17 | LP |

| Fungi | |||

| Aspergillus niger |

Can form “black mold” |

1160 | LP |

Table 2: D90 doses for some common germs.

In a German water disinfection guideline [16] the required value for water disinfection is 400 J/m2 for disinfection with UV-C pressure lamps. This value is higher than the D90 dose for most typical germs and can be considered as a guideline for designing disinfection systems. As the disinfection result is depending on many conditions such as surface properties or UV-C absorbtion, studies have to be performed for each system to prove the reliable disinfection!

When designing disinfection applications it is important to understand how to achieve a certain dose. For this, a few figures need to be understood:

- Radiant flux: The radiant flux is the total optical power output of the LED and is measured in units of [W]. This is a value that can be read from the datasheet.

- Irradiance: The irradiance is the amount of radiant flux received by a surface per irradiated area and is given in units of [W/m2]. This irradiance can be simulated (see Section 2.4) or measured for different configurations of LEDs.

- Exposure time: The time that a surface is exposed to radiation.

- Radiant exposure: The radiant exposure or fluence is the amount of energy received by a surface. It is calculated from Irradiance x Exposure time.

- Dose DXX: The dose is the amount of energy per surface required to achieve a certain percentage of disinfection (XX% inactivation). To achive a certain amount of disinfection, the surface needs to be exposed until it received a radiant exposure that equals the desired dose.

This implies that the time needed for a desired disinfection results can be estimated knowing the desired dose and the irradiation of your system. An example is shown in the following.

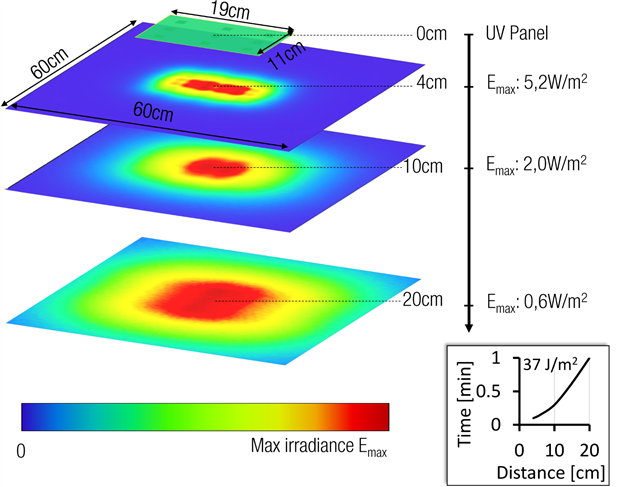

2.4 Example simulation

In Figure 5 the irradiation distribution for different heigths of a PCB with 9 WL-SUMW 15335327BA252 LEDs is shown.

Figure 5: Examples simulation of irradiation distribution

When the height increases, the irradiated area gets larger, but also the maximal irradiance decreases. As the irradiance decreases, the required exposure time for a certain dose increases with the square of the distance (Required exposure time ∝ Distance2) as shown in the inset for a dose of 37 J/m2 and in the following table:

| Distance | Irradiance |

Exposure time required for: Dose 37 ( J / m2 ) Dose 400( J / m2 ) |

|

|---|---|---|---|

| 4 cm | 5.2 W/m2 | 0.1 min | 1.3 min |

| 10 cm | 2.0 W/m2 | 0.3 min | 3.3 min |

| 20 cm | 0.6 W/m2 | 1.0 min | 11.1 min |

Table 3: Required exposure times for the example UV panel to achieve a certain dose, depending on the distance

This gives an indication of the required disinfection times and their dependence on the distance to the LEDs. Please note that this is just an estimation and the result depends on the LEDs and specific application. The performance in the application needs to be tested for each product separately.

3 Material degradation

UV light is known to lead to degradation in polymers [17], namely showing change of color, reduction of elasticity and strength that might result in cracks under stress. When using UVC LEDs the user has to consider using UV persistent materials such as metals and UV persitstent polymers in their applications. The UV resistance of materials may be checked by official labs [18].

According to BIFMA [19] the materials are tested with a dose of 288 kJ/m2 which would relate to ~720 disinfection cycles with using 400 J/m2 per disinfection cycle, or ~15 h of constant irradiation with the example UV panel from Section 2.4 at 4 cm distance. When testing the materials with this dose, some damage can be observed, whereas the amount of damage is depending on the type of material [20].

When sterilizing with UV-C light, there might be some concern regarding the generation of ozone. However this is not relevant for Würth Elektronik eiSos 275 nm LED as they emit well above the threshold for ozone generation. The generation of ozone becomes only relevant for wavelengths below 240 nm. When disinfecting water with 275 nm LEDs the light is aborbed by germs or escapes the water. The UV-C light is not stored in the water, meaning it can not do any damage after the disinfection process. This implies that the UV-C disinfected water is not harmful for consumption, but also has the disadvantage that there can be some reinfection of the water after the disinfection process.

4 Safety

UV-C light is especially potent of damaging the DNA of all cells, including human, animals and plants. Furthermore, UV-C radiation is naturally blocked by the ozone layer and does not reach the earth’s surface. This is why organsims on earth did not develop any repair mechanisms for the damage caused by the UV-C light. Because of this reason, UV-C is so potent for killing germs.

Figure 6: UV Warning symbol according to IEC 60417-6040.

However this also implies, that it is especially dangerous for our eyes and skin, causing long term damage such as skin cancer even long time after the exposure [21]. Great caution must be exercised when implementing UV-C light in applications. According to the maximum allowed dose per 8 h work day must not be higher than 30 J/m2. For continuous exposure this implies that the irradiation should not be more than 0.001 W/m2.

Appropriate personal protection equipment and shielding have to be applied to ensure product safety. The following example gives an idea of what the requirements for the shielding look like.

4.1 Example calculation of shielding material:

For the example UV panel shown above at a distance of 20 cm the maximum irradiation is 0.6 W/m2. To get below the maximum allowed irradiance of 0.001 W/m2 assuming a long time exposure, the shielding must have a transmission smaller than ~10-3. However, it is highly recommended to reduce the transmission of the shielding material even further, as the damage done by UV-C radiation is cumulative over a long time scale [21]. It has to be noted, that the irradiance is highly dependent on the distance to the UV-C source. In our example, if the distance between UV panel and skin/eyes is 4 cm, the transmission of a shielding material should already be smaller than ~10-4. For 1 cm distance the transmission should be below ~10-5.

4.2 Safety considerations

Several documents cope with the safety relating to UV-C radiation such as [22], [23], [24], [25] and [26]. To give a brief overview and tips for working with UV-C LEDs, some key points are summarized here:

- The exposure of the end user (eyes and skin) must be kept to a minimum. The limit is less than 30 J/m2 per 8 h work day.

- Products using UV-C must be marked with appropriate warning signs and an appropriate instructional safeguard and user manual must be included.

- Degradation of materials exposed to UV-C light needs to be considered.

- If too much UV-C light is leaving the application, such as in handheld lamps, all people that are potentially exposed need appropriate training and sufficient personal protection equipment such as face shields, gloves and protective clothing.

5 Summary

UV-C LEDs are an exciting new technology for disinfection purposes such as corona virus inactivation. But they will continue to play a big role in preventing future pandemics and coping with healthcare issues such as multiresistant germs. For general reduction of germs in many consumer applications, in air filtration systems, in water supplies and in food industry, the UV-C LEDs will continue to be in high demand long after the pandemic is over.

This application note explained the working mechanism of disinfection with UV-C and gives hints for the required radiation doses for different germs found from various publications. Furthermore it gives a calculation example using Würth Elektronik eiSos UV-C LEDs and also some tips and references on UV-C safety in your application.

A. Appendix

A.1. Literature

[1] "Researches on the Effect of Light upon Bacteria and other Organisms.," in Researches on the Effect of Light upon Bacteria and other Organisms., Proceedings of the Royal Society of London, 1877, p. 488.

[2] R. P. Rastogi, Richa, A. Kumar, M. B. Tyagi and R. P. Sinha, "Molecular Mechanisms of Ultraviolet Radiation-Induced DNA Damage and Repair," Journal of Nucleic Acids, 2010.

[3] S. E. Beck, R. A. Rodriguez, M. A. Hawkins, T. M. Hargy, T. C. Larason and K. G. Linden, "Comparison of UV-Induced Inactivation and RNA Damage in MS2 Phage across the Germicidal UV Spectrum," Applied and Environmental Microbiology, 16 02 2016.

[4] A. H. Malayeri, M. Mohseni, B. Cairns, J. R. Bolton, G. Chevrefils and E. Caron, "Fluence (UV Dose) Required to Achieve Incremental Log Inactivation of Bacteria, Protozoa, Viruses and Algae," IUVA News, pp. 4-6, 2016.

[5] W. J. Kowalski, V. Petraitis and T. J. W. Walsh, "2020 COVID-19 Coronavirus Ultraviolet Susceptibility," purplesun, 2020.

[6] N. Storm, L. G. McKay, G. Cennini and A. Griffiths, "Rapid and complete inactivation of SARS-CoV-2 by ultraviolet-C irradiation," Nature, 2020.

[7] C. S. H. e. al., "Susceptibility of SARS-CoV-2 to UV irradiation," American Journal of Infection Control, p. 1273−1275, 2020.

[8] M. Heßling, K. Hönes, P. Vatter and C. Lingenfelder, "Ultraviolet irradiation doses for coronavirus inactivation – review and analysis of coronavirus photoinactivation," GMS Hyg Infect Control., 2020.

[9] C. Bowker, A. Sain, M. Shatalov and J. and Ducoste, "Microbial UV fluence-response assessment using a novel UV-LED collimated beam system," Water Research, pp. 2011-2019, 2011.

[10] D. Battigelli, M. Sobsey and Lobe, "The inactivation of hepatitis A virus and other model viruses by UV irradiation," Water Sci. Technol., p. 339–342, 1993.

[11] G. Abraham, "The effect of ultraviolet radiation on the primary transcription of Influenza virus messenger RNAs," Virology, 1979.

[12] R. Rodríguez, S. Bounty and K. Linden, "Long-range quantitative PCR for determining inactivation of adenovirus 2 by ultraviolet light," Journal of Applied Microbiology, p. 1854–1865, 2013.

[13] X. Hu, S. Geng, X. Wang and C. and Hu, "Inactivation and photorepair of enteric pathogenic microorganisms with ultraviolet irradiation,," Environmental Engineering Science, p. 549–553, 2012.

[14] S. Cervero-Aragó, R. Sommer and R. and Araujo, "Effect of UV irradiation (253.7 nm) on free Legionella and Legionella associated with its amoebae hosts," Water Research, p. 299–309, 2014.

[15] M. Clauß, "Higher effectiveness of photoinactivation of bacterial spores, UV resistant vegetative bacteria and mold spores with 222 nm compared to 254 nm wavelength," Acta hydrochimica et hydrobiologica, p. 525–532, 2006.

[16] "Zur Sicherung eines regelkonformen Betriebs von UV-Desinfektionsgeräten nach DVGW-Arbeitsblatt W 294," DVGW Deutscher Verein des Gas- und Wasserfaches e.V., 2012.

[17] S. Lampman, Characterization and Failure Analysis of Plastics, ASM International, 2003.

[18] "VDE Prüfung + Zertifizierung - UV-C Beständigkeitsprüfung beim VDE-Institut," VDE, [Online]. Available: https://www.vde.com/tic-de/news/2019-1/uvc-bestaendigkeitspruefung. [Accessed 03 05 2021].

[19] "HEALTH CARE FURNITURE DESIGN - GUIDELINES FOR CLEANABILITY," BIFMA, 06 10 2014.

[20] P. Teska, R. Dayton, X. Li, J. Lamb and P. Strader, "Damage to Common Healthcare Polymer Surfaces from UV Exposure," Nano LIFE, 2020.

[21] "UVM RISK MANAGEMENT AND SAFETY - Hazards of Ultraviolet Radiation," The University of Vermont, [Online]. Available: https://www.uvm.edu/riskmanagement/hazards-ultraviolet-radiation. [Accessed 03 05 2021].

[22] "DIRECTIVE 2006/25/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL," Official Journal of the European Union, 05 04 2006.

[23] "DIN EN 62471 Photobiological safety of lamps and lamp systems," 2009.

[24] "Position Statement on Germicidal UV-C Irradiation - UV-C SAFETY GUIDELINES," Global Lighting Association 2020, 2020.

[25] "IEC 60335-1:2010/AMD2:2016 Sicherheit elektrischer Geräte für den Hausgebrauch und ähnliche Zwecke," 2016.

[26] "ISO 15858:2016: UV-C Devices — Safety information — Permissible human exposure," 2016.

IMPORTANT NOTICE

The Application Note is based on our knowledge and experience of typical requirements concerning these areas. It serves as general guidance and should not be construed as a commitment for the suitability for customer applications by Würth Elektronik eiSos GmbH & Co. KG. The information in the Application Note is subject to change without notice. This document and parts thereof must not be reproduced or copied without written permission, and contents thereof must not be imparted to a third party nor be used for any unauthorized purpose.

Würth Elektronik eiSos GmbH & Co. KG and its subsidiaries and affiliates (WE) are not liable for application assistance of any kind. Customers may use WE’s assistance and product recommendations for their applications and design. The responsibility for the applicability and use of WE Products in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate and investigate, where appropriate, and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not.

The technical specifications are stated in the current data sheet of the products. Therefore the customers shall use the data sheets and are cautioned to verify that data sheets are current. The current data sheets can be downloaded at www.we-online.com. Customers shall strictly observe any product-specific notes, cautions and warnings. WE reserves the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services.

WE DOES NOT WARRANT OR REPRESENT THAT ANY LICENSE, EITHER EXPRESS OR IMPLIED, IS GRANTED UNDER ANY PATENT RIGHT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL PROPERTY RIGHT RELATING TO ANY COMBINATION, MACHINE, OR PROCESS IN WHICH WE PRODUCTS OR SERVICES ARE USED. INFORMATION PUBLISHED BY WE REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE A LICENSE FROM WE TO USE SUCH PRODUCTS OR SERVICES OR A WARRANTY OR ENDORSEMENT THEREOF.

WE products are not authorized for use in safety-critical applications, or where a failure of the product is reasonably expected to cause severe personal injury or death. Moreover, WE products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. Customers shall inform WE about the intent of such usage before design-in stage. In certain customer applications requiring a very high level of safety and in which the malfunction or failure of an electronic component could endanger human life or health, customers must ensure that they have all necessary expertise in the safety and regulatory ramifications of their applications. Customers acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use of WE products in such safety-critical applications, notwithstanding any applications-related information or support that may be provided by WE.

CUSTOMERS SHALL INDEMNIFY WE AGAINST ANY DAMAGES ARISING OUT OF THE USE OF WE PRODUCTS IN SUCH SAFETY-CRITICAL APPLICATIONS.

USEFUL LINKS

Application Notes: http://www.we-online.com/app-notes

REDEXPERT Design Tool: http://www.we-online.com/redexpert

Component Selector: http://www.we-online.com/component-selector

Toolbox: http://www.we-online.com/toolbox

Product Catalog: http://katalog.we-online.de/en

DIRECT LINK

ANO008: Disinfection with UV-C LEDs

CONTACT INFORMATION

Würth Elektronik eiSos GmbH & Co. KG

Max-Eyth-Str. 1, 74638 Waldenburg, Germany

Tel.: +49 (0) 7942 / 945 – 0

Email: appnotes@we-online.de