LEDs – The Future of Horticultural Lighting

ANO002 BY DR. RICHARD BLAKEY

1. Introduction

Greenhouse farms may not be a new technology but with an every growing world population and the move towards sustainability, intensive yet highly efficient and standardized food production will increasingly become the norm in future years opening a potentially huge new agricultural sector that incorporates the latest technologies from the bioscience and engineering fields. But how can researchers and personnel from these separate fields understand the mutually dependent requirements of indoor greenhouses?

Greenhouses have a long history, purportedly from the roman era but were not used for viable intensive cultivation until the 20th century. Nowadays, there are millions of controlled protected plant enclosures all over the world, most of which use natural light. However, advancements in lighting, heating, watering and control systems have allowed the construction of vast, artificially lit, indoor greenhouses (Figure 1). These installations can produce significantly larger yields, than conventional agriculture and low-tech greenhouses.

Figure 1: Example of indoor greenhouse plant bed with LED light source

There are also several other advantages. The different stages and cycles of plant development can be controlled by providing different wavelengths of light to gain greater yields or reduce growing times. Water usage is greatly reduced due to reduced evaporation and the control of humidity and temperature in the installation. The control or elimination of insectile, fungal or bacterial pests is also more effective because of the closed system. In addition, the carbon footprint of food production and supply can also be significantly reduced by building the installations close to population centers, reducing transport requirements.

One of the most significant future advancements in the viability of indoor greenhouses has been the maturation of LED technology. Originally, LEDs were expensive and extremely limited in the wavelengths of light they could generate. However, as advancements in their fabrication have progressed, LEDs have become the preferred solution for indoor cultivation. LEDs can now be made to emit very specific bandwidths of light while being extremely rugged and relatively small when compared to other lighting technologies. In addition, LEDs have a long life, have low voltage requirements and do not generate as much excessive heat making them exceptionally efficient. This will greatly reduce the operating costs of indoor greenhouses.

2. Spectral requirements of plants

Photosynthesis is the process that converts water and carbon dioxide into complex carbohydrates (i.e. sugars) and oxygen using energy from light. However, although the energy radiated by the sun that reaches the earth’s surface consists of the entire spectrum of visible light (and more), plants only utilize specific frequencies of light for photosynthesis. These frequencies are related to the absorption characteristics of different pigments that are present within organelles called chloroplasts that are responsible for different functions of photosynthesis. The majority of these pigments absorb light in the wavelengths that correspond to the colors blue and red. This is why most leaves appear green as these wavelengths are not absorbed, and carrots appear orange as they contain very little chlorophyll. The most common pigments are chlorophyll A, chlorophyll B and the carotenoids.

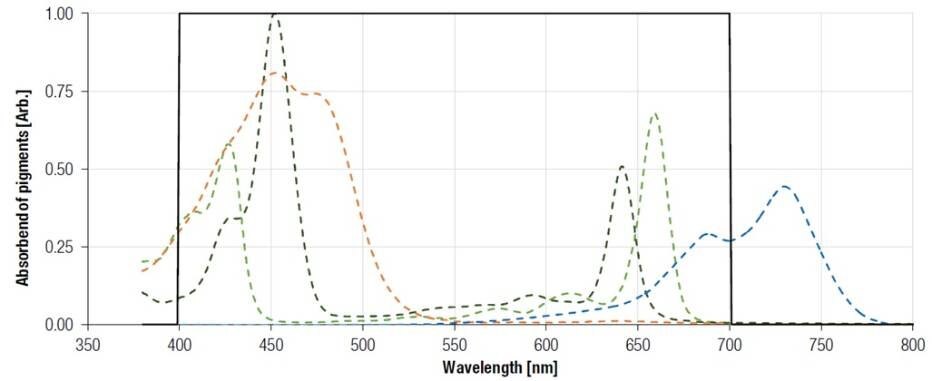

Figure 2: Characteristic absorption spectra of different pigments used for photosynthesis [1]

These frequencies are called the photosynthetic active radiation (PAR) region and defined as 400 to 700 nm. Chlorophyll A is the primary photo-pigment accounting for around 75 % of photosynthetic activity and has absorption peaks at ~435 nm and ~675 nm. Chlorophyll B, once thought to be an accessory photo-pigment, extends the range of wavelengths that can be used for photosynthesis with absorption peaks at ~460 nm and ~640 nm. Energy from these wavelengths is captured by chlorophyll B before passing it to chlorophyll A through electron spin resonance. All higher plants have these two pigments accounting for their green color.

Carotenoids have a comparatively much wider wavelength absorption range than the chlorophylls with an absorption range of ~400 nm to ~510 nm. In addition to their accessory light harvesting function, they have a much more complex role than initially thought, protecting chlorophylls from photooxidation when light intensity is high, in the low wavelength (i.e. higher energy) wavelength ranges [2]. This is why the absorption wavelengths of the carotenoids overlap with that of the chlorophylls. Additionally, phytochromes are photoreceptors (light sensors) that regulate numerous processes, such as chlorophyll synthesis. In spite of the absorbance wavelengths laying mostly outside of the PAR region, they are critical to plant development.

As plants are stationary they have evolved to respond to different frequencies and intensities of light that are available and linked to responses to growing in the shade, circadian rhythm, circannual rhythm and weather variations. In this way, artificial light of different wavelengths can be used to orchestrate and manipulate the growth and development stages of plants. These responses, which include photosynthesis rate, photomorphogenesis (plant anatomy), phototropism (direction of growth) and photonasty (non-directional changes, e.g. flower opening), are dependent on a wide variety of photoreceptors and can be particular to specific orders, families and genus of plants [3].

3. LEDs in Horticulture

Light emitting diodes are solid-state, light generating components that, as previously stated, have become and will continue to be one of the greatest drivers in the expansion of internal greenhouses due to their advantages over incandescent bulbs, fluorescent bulbs, high-pressure sodium lamps and mercury lamps. Their main advantage stems from their ability to generate specific wavelengths of light. As we saw in the previous chapter, plants only utilize a limited range of wavelengths and have varying requirements at different frequencies. It would be highly inefficient to consume electricity generating wavelengths of light that the plant will not utilize.

Therefore, manufactures usually concentrate on LEDs with wavelengths of 660 nm (red) and 450nm (blue) usually in a rough ratio of 2:1. However, recent investigations have revealed the influences of wavelengths of light outside that of the conventional red and blue.

- Red light (630 – 660 nm) is the main driver of photosynthesis and is essential for the growth of stems. This wavelength also regulates flowering, dormancy and seed germination.

- Blue light (400 – 520 nm) is another key wavelength for photosynthesis but must be carefully controlled and mixed with other frequencies as over exposure at this wavelength may inhibit growth. This wavelength has also been linked to the regulation of chlorophyll concentration, lateral bud growth and leaf thickness.

- Far red light (720 – 740 nm) which is in the IR spectrum, influences germination and can reduce the flowering time of plants but also increase stem length, again as part of the “shade avoidance response”.

- Green light (500 – 600 nm) was once disregarded as being unimportant to plant development, but recent investigations have revealed that plants in the shade of others are particularly responsive to this wavelength as part of the “shade avoidance response”.

- UV light (280 – 400 nm) is still highly experimental in the cultivation of plants. Although this wavelength is mutagenic, some plants (e.g. lettuce, tomato) are much more resistant to these wavelengths. Studies suggest that these wavelengths can be used as fungal control on insensitive species. Additionally, UV light may be responsible for the generation of certain protective molecules like anti-oxidants and phenols, which are important for human nutrition.

However, it must be remembered that every type of plant will respond differently to various combinations of light wavelength and intensity. In addition, different physical characteristics are preferred for different types of plants. For example, it is desirable for salad vegetables to have thin, light leaves for improved texture when eating, whereas in Aloe vera thick leaves are desirable to produce more latex. Regarding flowering, decorative plants need to maintain their flowers for as long a duration as possible while in pineapples, it is optimum to inhibit the flowering process to better control the harvest period. As a result, indoor greenhouse operators and artificial light unit manufacturers are always looking for new combinations of wavelengths that are particularly catered to the light recipe of specific species and even cultivars (sub-species) of plants.

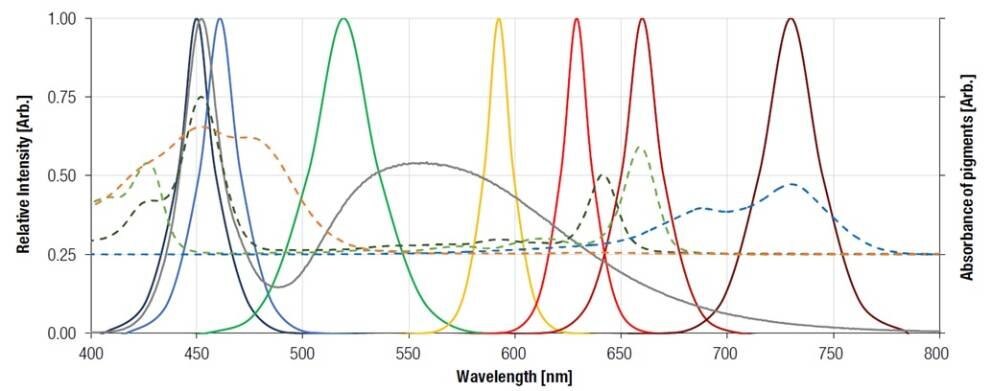

Tomeet these requirements,Würth Elektronik offers the WL-SMDC SMD Mono-color Ceramic LEDWaterclear range of LEDs (Figure 3). The WL-SMDC range has been expanded to include wavelengths of 450 nm (Deep Blue), 660 nm (Hyper Red) and 730 nm (Far Red), which have been selected to match the absorption spectra of photosynthetic pigments. In addition to the existing products in the range, a diverse range of combinations is possible that can be catered to the target cultivar (Figure 4).

Figure 3: Würth Elektronik WL-SMDC SMD Mono-color Ceramic LED Waterclear

Figure 4: The emission spectra of WL-SMDC LEDs overlaid on the absorption spectra of photosynthetic pigments

4. Important parameters, metrics and units

As with any new application, different metrics and parameters have been developed by different organizations and companies to measure, quantify and qualify the efficiency of artificial indoor systems. Some effort has been made in recent years to standardize these parameters, notably the American Society of Agricultural and Biological Engineering (ASABE) who have produced several documents to identify and coordinate the use of LEDs for plant growth with a number of standards and guidelines regarding the methods of measurement and testing to quantify energy consumption and performance characteristics. Until very recently, parameters have been based upon the human perception of light, which is biased towards the green/yellow wavelengths and against blue and red wavelengths. This is why conventional parameters, such as lumens, cannot be used. Listed below are the most important parameters concerning LEDs in horticulture [4].

- Wavelength (λ, nm) – this specifies the wavelength of light emitted by the LED.

- Photosynthetically active radiation (PAR, ~400 nm - ~700 nm) – this is the conventionally used range of frequencies of light that is required by plants to perform photosynthesis (Figure 2). This number can sometimes be misleading as all wavelengths are given equal importance for photosynthesis although as we have seen above, red and blue are the main drivers of photosynthesis. This means the wavelengths of a green LED may fall within the PAR range but will have a very limited effect on plant growth.

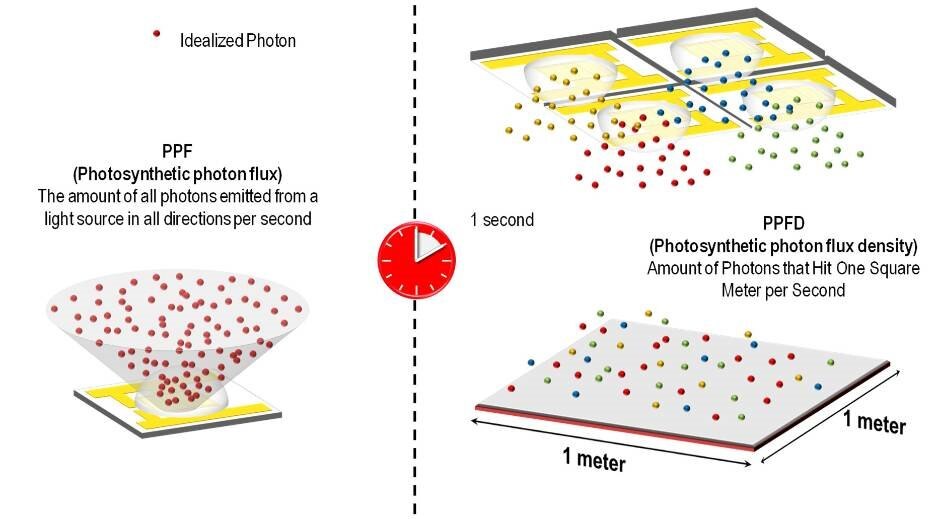

- Photosynthetic photon flux (PPF, μmol·s-1– this quantifies the total amount of photosynthetically active photons that are produced by LEDs each second. Although it may seem strange to an electrical engineer to quantify the output of a light source by the number of photons emitted, it must be remembered that photosynthesis is a biochemical process that can be quantified by the number of sugar molecules generated per number of photons, even though photons of different wavelengths have different energy levels. The conversion from electrical power to PPF is performed using the Plank-Einstein relation and Avogadro’s number and is the sum of all photons generated in the wavelength range.

Figure 5: The difference between Photosynthetic Photon Flux on the left and Photosynthetic Photon Flux Density on the right with several colors

- Photosynthetic photon flux density (PPFD, μmol·m-2·s-1)– this quantifies the total amount of photosynthetically active photons that reach the target area per second. This parameter is highly reliant upon the distance and angle from the source. This is usually measured using a quantum meter sensitive only to PAR wavelengths.

- Photon efficacy (μmol·J) – this parameter quantifies how efficient the LED is at creating PPF per joule of electrical energy used.

- Wall-plug efficiency (WPE, %) – this is defined as the energy conversion efficiency, a ratio of the electrical power to the optical power.

- R-B ratio – this ratio quantifies the ratio of red to blue light emitted by the LED system.

5. Summary

The improvement in efficiency, optical power, price and life span have moved LEDs from the research stage of development to an innovative, viable alternative to conventional lighting sources in the application of horticulture. Although the exact influence of wavelength ratios and the role of wavelengths outside of red and blue needs to be investigated and understood, LEDs will continue to take market share from other lighting sources and will become dominant in the coming years. With the release of the extended WL-SMDC, Würth Elektronik has LEDs to match the wavelengths that are essential for photosynthesis in addition to any special requirements that may be required for specific types of plant.

6. References

[1] Jigang, L., Gang, L., et al, 2011, Phytochrome Signaling Mechanisms, The Arabidopsis Book / American Society of Plant Biologists, 9, e0148.

[2] Yamamoto, H.Y., Bassi, R., 2006, Chapter 30: Carotenoids: Localisation and function. Oxygenic Photosynthesis: The Light Reactions, P539-563, Springer Science & Business Media.

[3] Hogewoning, S.W., Douwstra, P., et al, 2010, An artificial solar spectrum substantially alters plant development compared with climate room irradiance spectra, Journal of Experimental Botany, 61 (5), P1267-1276.

[4] Salisbury, F.B., 1996, Chapter 9: Electromagnetic Radiation, Units, Symbols, and Terminology for Plant Physiology: A Reference for Presentation of Research Results in the Plant Sciences, P75-80, Oxford University Press.

IMPORTANT NOTICE

The Application Note is based on our knowledge and experience of typical requirements concerning these areas. It serves as general guidance and should not be construed as a commitment for the suitability for customer applications by Würth Elektronik eiSos GmbH & Co. KG. The information in the Application Note is subject to change without notice. This document and parts thereof must not be reproduced or copied without written permission, and contents thereof must not be imparted to a third party nor be used for any unauthorized purpose.

Würth Elektronik eiSos GmbH & Co. KG and its subsidiaries and affiliates (WE) are not liable for application assistance of any kind. Customers may use WE’s assistance and product recommendations for their applications and design. The responsibility for the applicability and use of WE Products in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate and investigate, where appropriate, and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not.

The technical specifications are stated in the current data sheet of the products. Therefore the customers shall use the data sheets and are cautioned to verify that data sheets are current. The current data sheets can be downloaded at www.we-online.com. Customers shall strictly observe any product-specific notes, cautions and warnings.WE reserves the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services.

WE DOES NOT WARRANT OR REPRESENT THAT ANY LICENSE, EITHER EXPRESS OR IMPLIED, IS GRANTED UNDER ANY PATENT RIGHT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL PROPERTY RIGHT RELATING TO ANY COMBINATION, MACHINE, OR PROCESS INWHICHWE PRODUCTS OR SERVICES ARE USED. INFORMATION PUBLISHED BY WE REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE A LICENSE FROM WE TO USE SUCH PRODUCTS OR SERVICES OR A WARRANTY OR

ENDORSEMENT THEREOF.

WE products are not authorized for use in safety-critical applications, or where a failure of the product is reasonably expected to cause severe personal injury or death. Moreover, WE products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. Customers shall inform WE about the intent of such usage before design-in stage. In certain customer applications requiring a very high level of safety and in which the malfunction or failure of an electronic component could endanger human life or health, customers must ensure that they have all necessary expertise in the safety and regulatory ramifications of their applications.

Customers acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use ofWE products in such safety-critical applications, notwithstanding any applications related information or support that may be provided by WE. CUSTOMERS SHALL INDEMNIFY WE AGAINST ANY DAMAGES ARISING OUT OF THE USE OF WE PRODUCTS IN SUCH SAFETY-CRITICAL APPLICATIONS.

USEFUL LINKS

Application Notes: www.we-online.com/appnotes

REDEXPERT Design Tool: www.we-online.com/redexpert

Toolbox: www.we-online.com/toolbox

Product Catalog: www.we-online.com/products

DIRECT LINKS

ANO002: LEDs – The Future of Horticultural Lighting

CONTACT INFORMATION

Würth Elektronik eiSos GmbH & Co. KG

Max-Eyth-Str. 1 / 74638 Waldenburg / Germany

Tel. +49 7942 945 - 0 / Fax +49 7942 945 - 5000

Top Comments