APPLICATION NOTE

Selection and Characteristics of WE-FSFS

(Flexible Sintered Ferrite Sheet)

BY JORGE VICTORIA AHUIR

1. About WE-FSFS

Würth Elektronik eiSos Flexible Sintered Ferrite Sheet (WE-FSFS) is a product designed for high performance magnetic flux redirection. The correct management of the magnetic flux improves the energy and data transfer in inductive coupled systems (NFC, RFID, Wireless Power, etc.), achieving a higher efficiency and communication range.

Size and weight are critical parameters in today’s electronic devices, and with the last generation ferrite compositions used in WE-FSFS optimal results are achieved with minimal thickness.

The WE-FSFS is composed by three layers:

- PET protective layer: High surface resistivity and adhesive strength to protect the ferrite layer.

- Pre-cut Sintered Ferrite Layer: It is the core of the product. Its magnetic properties concentrate and control the external magnetic fields.

- Adhesive layer: High adhesive strength to protect the ferrite and to apply the product.

Figure 2: Construction of WE-FSFS sheet

Figure 2: Construction of WE-FSFS sheet

2. Permeability

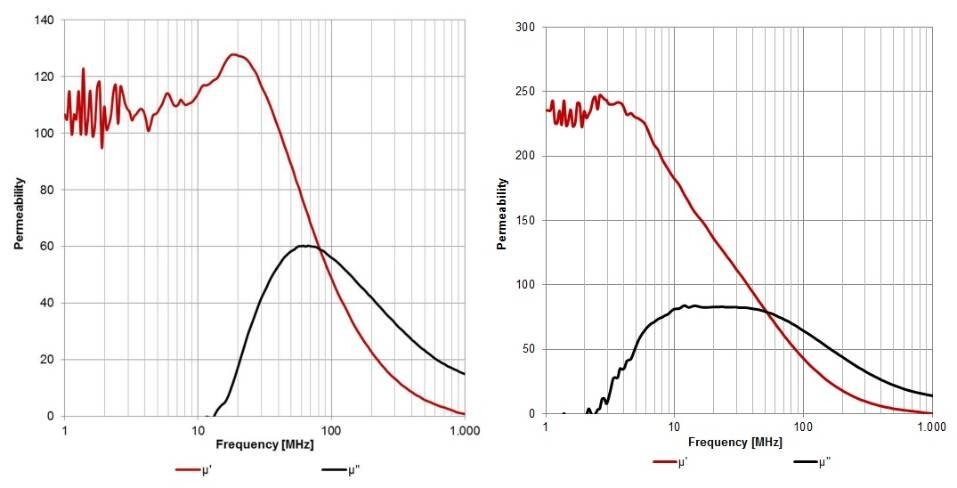

The electromagnetic properties of the WE-FSFS materials are described by their relative 1 permability curves:

Figure 3: Relative permeability of 364 and 354 material

μ' is the ideal permeability, and it is the ability of the material to concentrate and redirect the magnetic flux. With a high μ’ a WE-FSFS sheet can concentrate more magnetic flux to improve the efficiency of data or energy transfer.

μ” represent the losses in the material. These losses are due to the conversion of part of the magnetic flux into heat. With a high μ", the sheet can absorb noise and convert it into heat.

Both μ’ and μ" are frequency dependent, that is why the material needs to be chosen carefully for each application. For example, for RFID 13,56 MHz applications, WE-FSFS 364 material will provide good redirection at the working frequency, and absorption for frequencies higher than 13,56 MHz (noise).

3. Flexibility

Thanks to its structure WE-FSFS, despite its thickness, is resistant enough to support manipulation during transport, storage and assembly. The ferrite layer is cut by laser in 2 mm x 2 mm size squares, protected on one side by the PET layer and on the other by the double-sided adhesive layer. This structure provides enough flexibility to stand repeated bending without a decrease on the electromagnetic performance of the product.

WE eiSos test description

Bending tests have been performed by Würth Elektronik eiSos in order to guarantee the electromagnetic properties of WE-FSFS.

Figure 4: WE-FSFS bending test

A 10 cm bending radius deformation is applied and maintained during 30 sec. The cycle is repeated 20 times. After the test the electromagnetic properties of the specimens are measured and proved to be inside the specifications.

4. Thickness

Once is chosen the correct material, it is needed to select the appropriate thickness. The higher the thickness, the higher the effect of the ferrite sheet (flux redirection, noise absorption, inductance increase). We will see the effect of the thickness with three examples.

4.1. Inductance increase

Thanks to its high μ’, when WE-FSFS is attached to a planar coil there is an increase of the inductance without a Q decrease. We are used to see the same effect when inserting a ferrite core into a traditional solenoid coil. We tested three different thicknesses of WE-FSFS 354 material over a PCB coil.

Figure 5: Measurement of inductance increase of a PCB coil

Figure 5: Measurement of inductance increase of a PCB coil

4.2. Flux Redirection

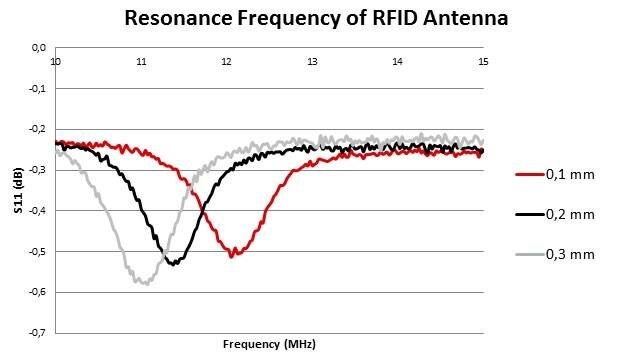

When a metal plate is placed close to a RFID antenna, this cannot work. The flux generated by the antenna crosses the metal generating eddy currents due to its conductivity. The inductance of the antenna will then decrease and the resonance frequency will shift to higher frequencies. If it is not around 13,56 MHz the communication is not possible anymore.

With a ferrite sheet attached between the antenna and the metal we can eliminate this effect, increase the inductance and shift to lower frequencies. The higher the thickness we use, the higher the shift. Correct thickness must be chosen in each application to reach the better tuning.

We placed WE-FSFS 364 ferrite sheets of different thickness between an RFID antenna and an aluminium plate 2 mm thick, and measured the frequency shift:

Figure 6: Resonance frequency shift with different thicknesses

4.3. Noise Absorption:

Due to its μ" at a wide frequency range, WE-FSFS products can be used as noise absorbers. When we increase the thickness we increase the capacity of the sheet to store and convert energy into heat.

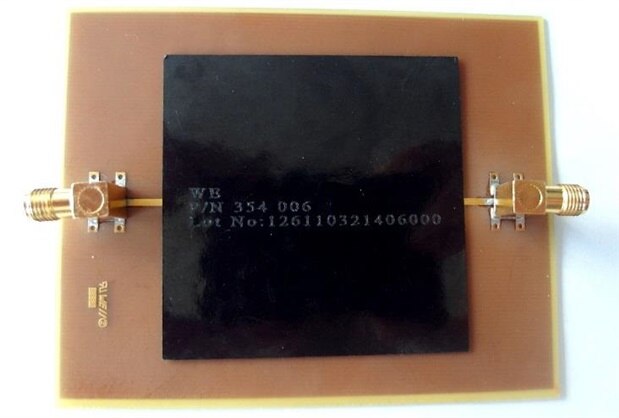

We prove it placing 60 x 60 mm samples of different thickness of WE-FSFS 354 over a Micro Strip Line and measure the absorption loss:

Figure 7: Test Setup with a Micro Strip Line

Figure 8: Insertion Loss (S21) over a Micro Strip Line

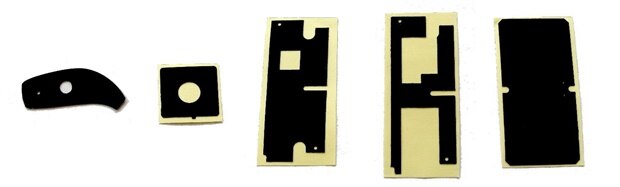

5. Dimensions

WE-FSFS can be optimized in order to fit different applications. Special designs can be supplied after request. It is important to remember the structure of the ferrite sheet (square cut 2 mm x 2 mm) and avoid when possible sharp angles and thin bridges.

Figure 9: Examples of WE-FSFS custom cuts

Note: Ii is not possible to produce a WE-FSFS sheet bigger than 120 mm x 120 mm. When bigger dimensions are needed it is possible to combine various sheets without a significant performance reduction.

6. Product Characteristics

Product | WE Order Code | Farnell Order Code | L

(mm) | W

(mm) | H

(mm) | RSurface

(GΩ) | μꞋ @ 1 (MHz) | μꞋ @ 13,56 (MHz) | μꞋꞋ @ 1 (MHz) | μꞋꞋ @ 13,56 (MHz) |

WE-FSFS 354

(WPC-Qi, PMA) | 120 | 120 |

| > 1 | 230 | 150 | < 2 | 90 | ||

120 | 120 |

| > 1 | 230 | 150 | < 2 | 90 | |||

120 | 120 |

| > 1 | 230 | 150 | < 2 | 90 | |||

60 | 60 |

| > 1 | 230 | 150 | < 2 | 90 | |||

60 | 60 |

| > 1 | 230 | 150 | < 2 | 90 | |||

60 | 60 |

| > 1 | 230 | 150 | < 2 | 90 | |||

WE-FSFS 364

(RFID, NFC, A4WP, WCT) | 120 | 120 |

| > 1 | 110 | 120 | < 2 | 2 | ||

120 | 120 |

| > 1 | 110 | 120 | < 2 | 2 | |||

120 | 120 |

| > 1 | 110 | 120 | < 2 | 2 | |||

60 | 60 |

| > 1 | 110 | 120 | < 2 | 2 | |||

60 | 60 |

| > 1 | 110 | 120 | < 2 | 2 | |||

60 | 60 |

| > 1 | 110 | 120 | < 2 | 2 |

IMPORTANTE NOTICE

Würth Elektronik eiSos GmbH & Co. KG and its subsidiaries and affiliates (WE) are not liable for application assistance of any kind. Customers may use WE’s assistance and product recommendations for their applications and design. The responsibility for the applicability and use of WE Products in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate, where appropriate to investigate and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not.

The technical specifications are stated in the current data sheet of the products. Therefore the customers shall use the data sheets and are cautioned to verify that data sheets are current. The current data sheets can be downloaded at www.we-online.com. Customers shall strictly observe any product-specific notes, cautions and warnings. WE reserve the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services.

WE DOES NOT WARRANT OR REPRESENT THAT ANY LICENSE, EITHER EXPRESS OR IMPLIED, IS GRANTED UNDER ANY PATENT RIGHT, COPYRIGHT, MASK WORK RIGHT, OR OTHER INTELLECTUAL PROPERTY RIGHT RELATING TO ANY COMBINATION, MACHINE, OR PROCESS IN WHICH WE PRODUCTS OR SERVICES ARE USED. INFORMATION PUBLISHED BY WE REGARDING THIRD-PARTY PRODUCTS OR SERVICES DOES NOT CONSTITUTE A LICENSE FROM WE TO USE SUCH PRODUCTS OR SERVICES OR A WARRANTY OR ENDORSEMENT THEREOF.

WE products are not authorized for use in safety-critical applications, or where a failure of the product is reasonably expected to cause severe personal injury or death. Moreover WE products are neither designed nor intended for use in areas such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. Customers shall inform WE about the intent of such usage before design-in stage. In certain customer applications requiring a very high level of safety and in which the malfunction or failure of an electronic component could endanger human life or health customers must ensure that they have all necessary expertise in the safety and regulatory ramifications of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products and any use of WE products in such safety-critical applications, notwithstanding any applications-related information or support that may be provided by WE. CUSTOMERS SHALL INDEMNIFY WE AGAINST ANY DAMAGES ARISING OUT OF THE USE OF WE PRODUCTS IN SUCH SAFETY-CRITICAL APPLICATIONS.

USEFUL LINKS

Application Notes: http://www.we-online.com/app-notes

Component Selector: http://www.we-online.com/component-selector

Toolbox: http://www.we-online.com/toolbox

Product Catalog: http://katalog.we-online.de/en/

DIRECT LINK

ANP022: Selection and Characteristics of WE-FSFS

CONTACT INFORMATION

Würth Elektronik eiSos GmbH & Co. KG

Max-Eyth-Str. 1, 74638 Waldenburg, Germany

Tel.: +49 (0) 7942 / 945 – 0

Email: appnotes@we-online.de