Is there a PCB construction that creates an area of the board that can easily be broken?

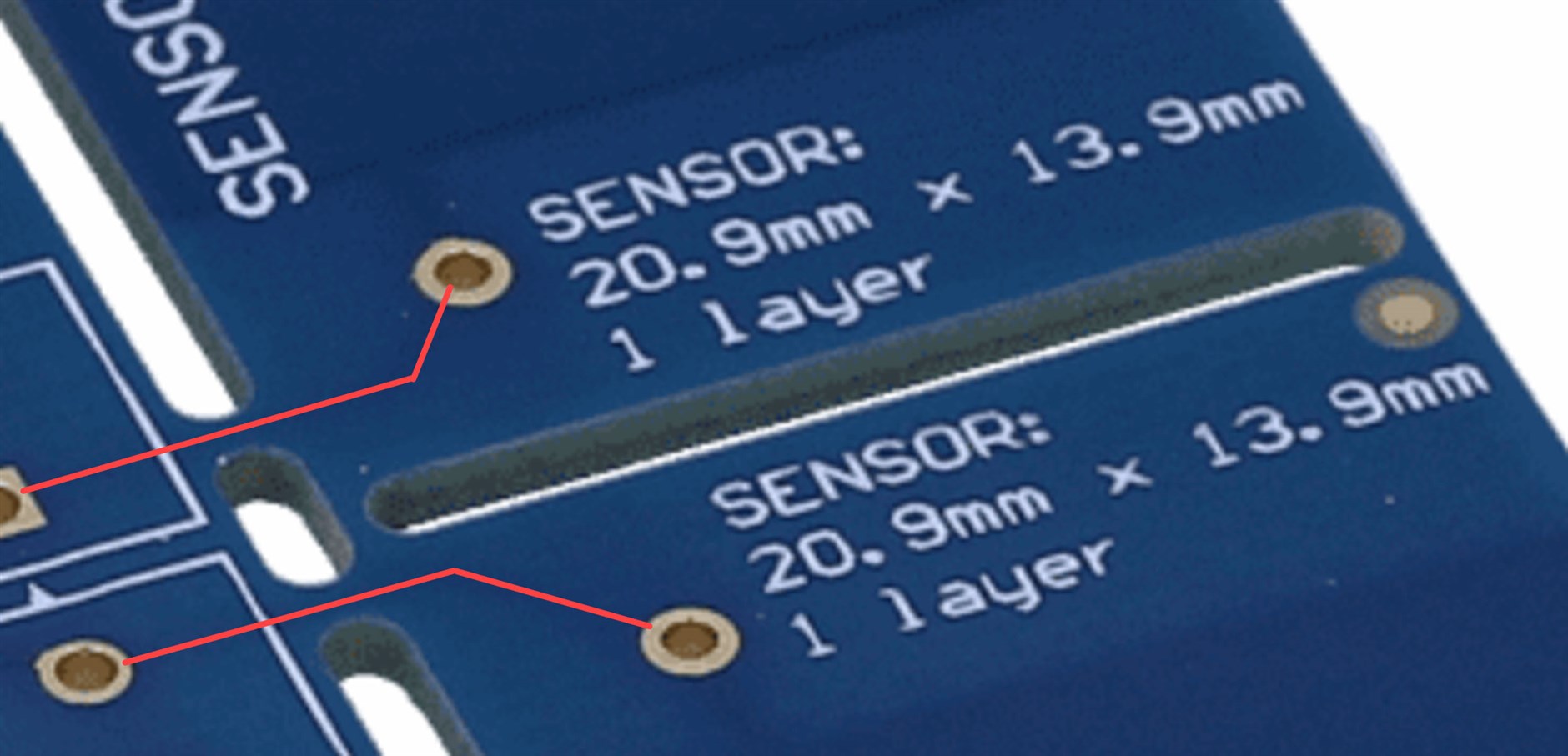

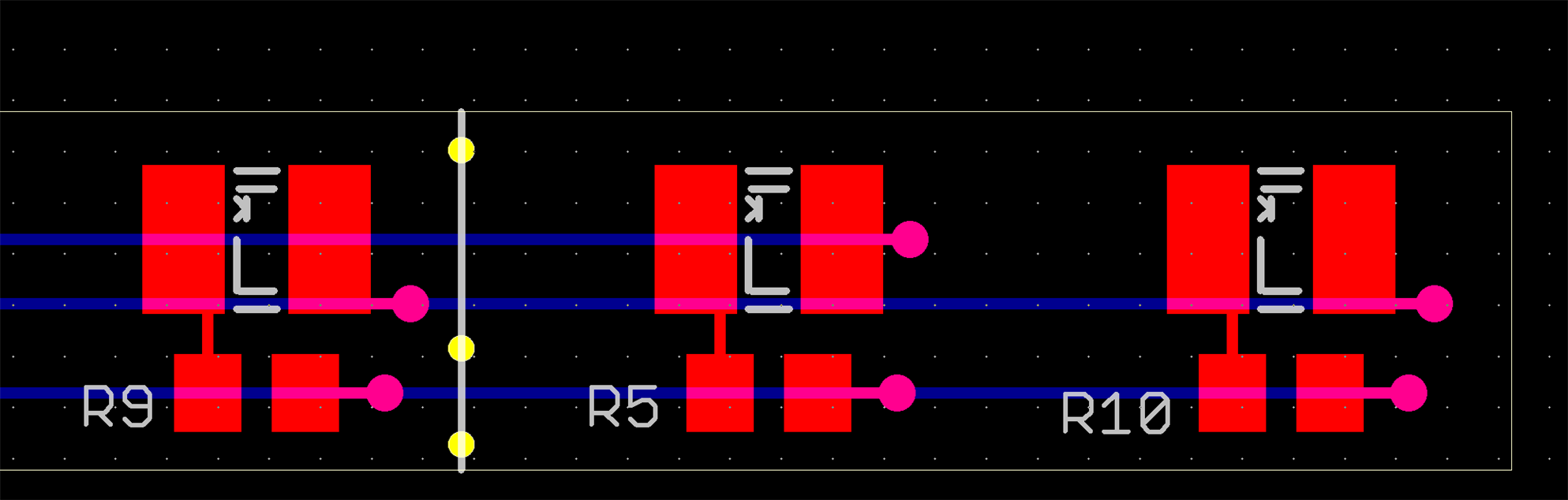

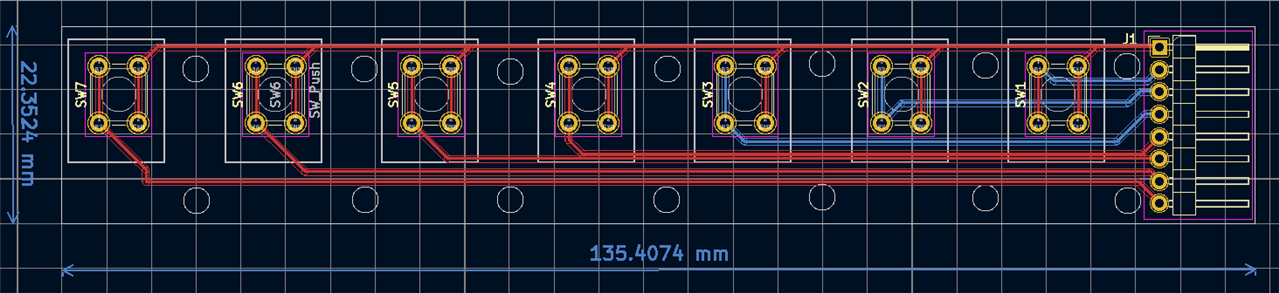

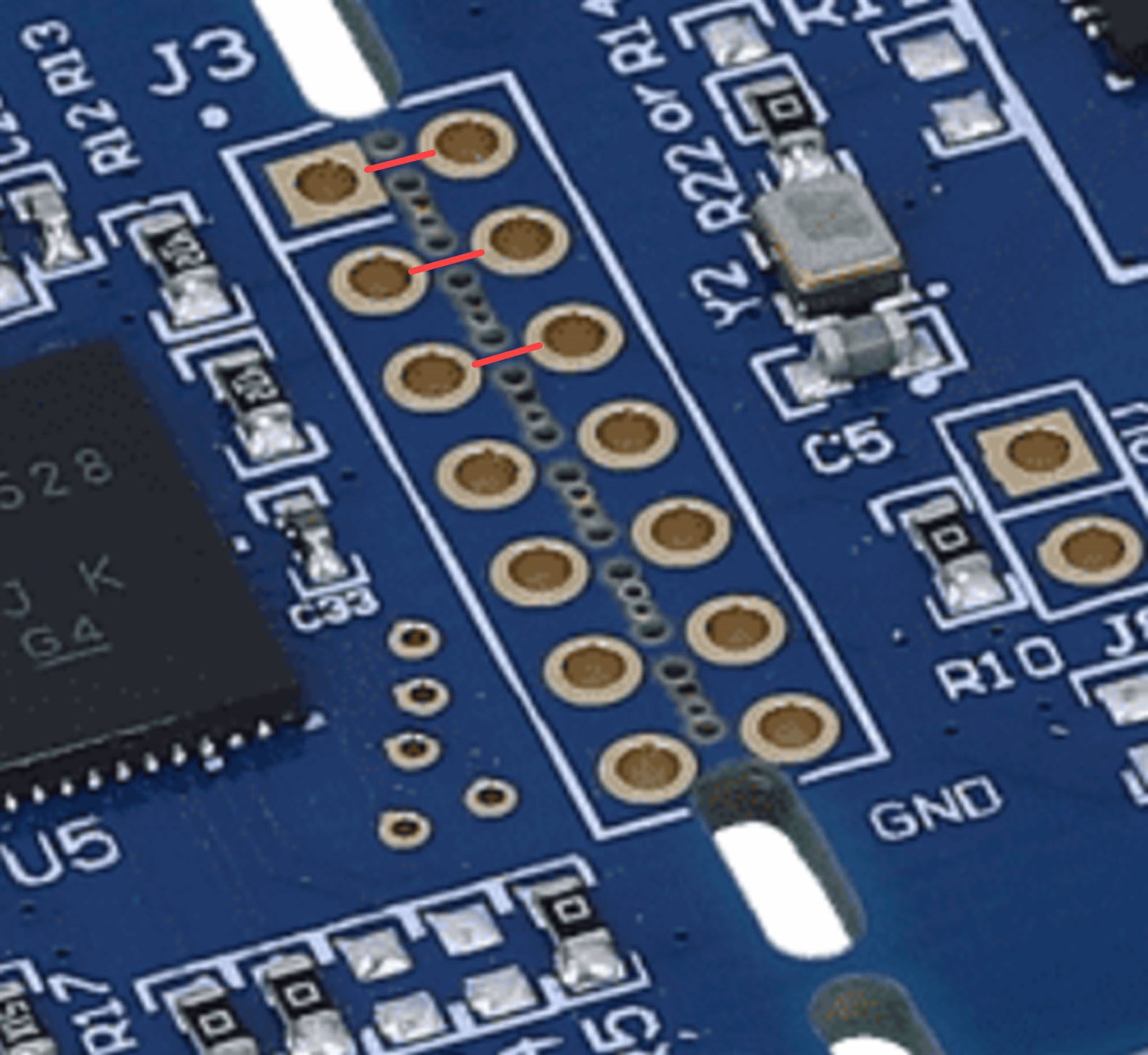

In the sketch the dotted section could be easily broken to reduce the size PCB. My design would have each breakout section containing a button(s) that wire back to a single edge connector. Breaking off pieces of the PCB reduces the number of buttons.

I was wonder if such a technique is used and what it might be called when constructing a PCB?

(image sources: TI website)

(image sources: TI website)