Calling all hand builders.

I am building a homebrew semi-automatic solder paste dispenser to build one-off SMD boards.

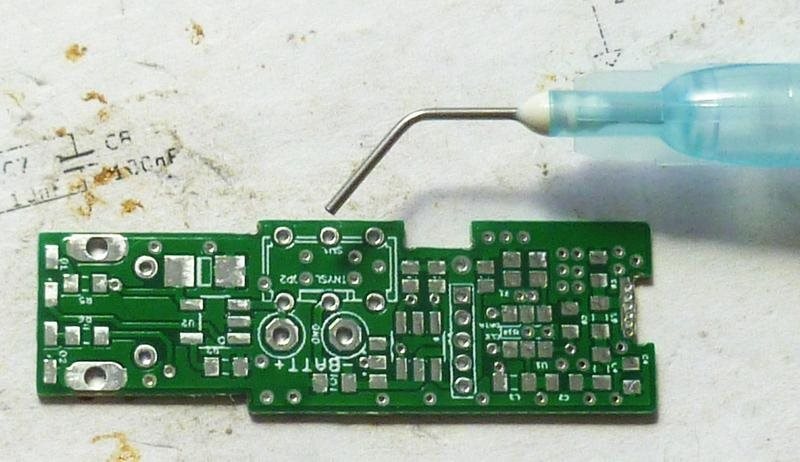

I attach a picture of where I am up to below.

The system uses a 1mL syringe with a 22G needle being driven by a threaded rod connected to a miniature motor and gearbox.

The motor is controlled by an Arduino that can activate the motor for a variety of milliseconds to deliver the correct solder paste 'droplet' size.

My problem is selecting a solder paste with the correct viscosity.

Whilst testing I used various household 'pastes' to save wasting expensive solder paste. I tried toothpaste and Dijon mustard and the system delivered acceptable sized droplets (see toothpaste attached below):-

However when I tried my solder paste, the system delivered the paste but due to it's thicker consistency it continued to 'creep' out the needle after the motor advance.

Clearly the paste is too thick and unduly pressurises the system, slowly releasing over time rather than being delivered all in one droplet.

The effect is that I get a slowly emerging 'worm' of paste rather than a nice droplet.

So my plea for help is this.

Without going to the expense of buying a variety of solder pastes in the hope one is suitable, does someone in the community have experience of hand delivering droplets

of 'leaded' solder paste in a similar manner. And can you kindly save me a lot of experimenting, by suggesting a suitable paste please?

Thanks in anticipation......

Dave