There is nothing quite like solving a problem to help develop new skills. In this case I have found a library solution to what I want to achieve but it is not RP2040 compatible and of course it does not use PIO, which is the skill I am trying to acquire.

Having seen other members deliver some great PIO related projects, I thought this would be a great opportunity to build a solution together while helping me, and hopefully others, grasp how to develop PIO code from scratch.

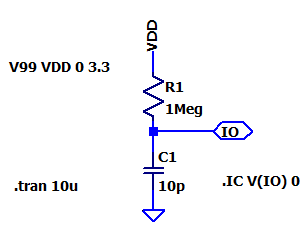

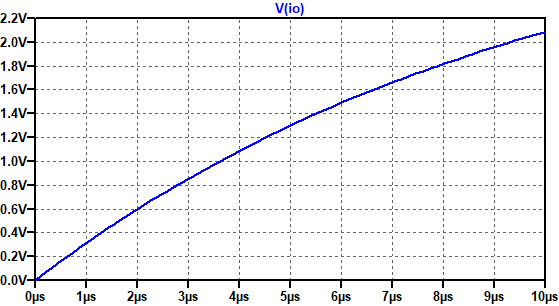

Basically I want to create a capacitance touch or proximity sensor using a Raspberry Pi Pico (RP2040) board.

There is an Arduino library that can do this: https://github.com/PaulStoffregen/CapacitiveSensor

But it is not RP2040 compatible: https://github.com/PaulStoffregen/CapacitiveSensor/issues/42

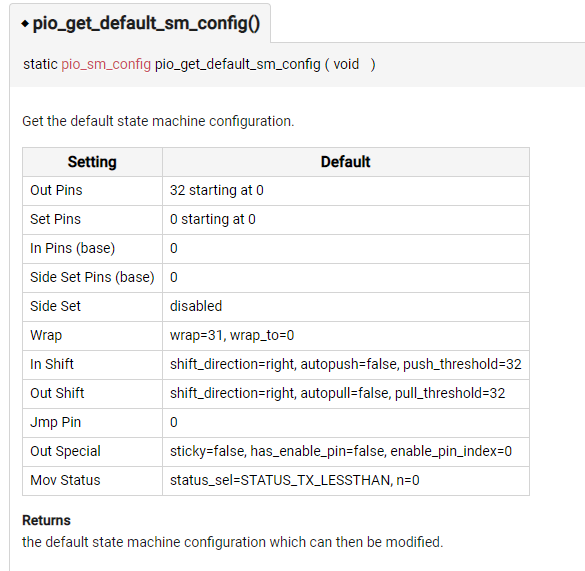

Having reviewed this library, it appears on face value to be well suited to use PIO. Only, I don't know how to start.

As far as I can make out, there is only one function to apply PIO... but maybe others see things differently. I'm keen to learn more.

// Private Methods /////////////////////////////////////////////////////////////

// Functions only available to other functions in this library

int CapacitiveSensor::SenseOneCycle(void)

{

noInterrupts();

DIRECT_WRITE_LOW(sReg, sBit); // sendPin Register low

DIRECT_MODE_INPUT(rReg, rBit); // receivePin to input (pullups are off)

DIRECT_MODE_OUTPUT(rReg, rBit); // receivePin to OUTPUT

DIRECT_WRITE_LOW(rReg, rBit); // pin is now LOW AND OUTPUT

delayMicroseconds(10);

DIRECT_MODE_INPUT(rReg, rBit); // receivePin to input (pullups are off)

DIRECT_WRITE_HIGH(sReg, sBit); // sendPin High

interrupts();

while ( !DIRECT_READ(rReg, rBit) && (total < CS_Timeout_Millis) ) { // while receive pin is LOW AND total is positive value

total++;

}

//Serial.print("SenseOneCycle(1): ");

//Serial.println(total);

if (total > CS_Timeout_Millis) {

return -2; // total variable over timeout

}

// set receive pin HIGH briefly to charge up fully - because the while loop above will exit when pin is ~ 2.5V

noInterrupts();

DIRECT_WRITE_HIGH(rReg, rBit);

DIRECT_MODE_OUTPUT(rReg, rBit); // receivePin to OUTPUT - pin is now HIGH AND OUTPUT

DIRECT_WRITE_HIGH(rReg, rBit);

DIRECT_MODE_INPUT(rReg, rBit); // receivePin to INPUT (pullup is off)

DIRECT_WRITE_LOW(sReg, sBit); // sendPin LOW

interrupts();

#ifdef FIVE_VOLT_TOLERANCE_WORKAROUND

DIRECT_MODE_OUTPUT(rReg, rBit);

DIRECT_WRITE_LOW(rReg, rBit);

delayMicroseconds(10);

DIRECT_MODE_INPUT(rReg, rBit); // receivePin to INPUT (pullup is off)

#else

while ( DIRECT_READ(rReg, rBit) && (total < CS_Timeout_Millis) ) { // while receive pin is HIGH AND total is less than timeout

total++;

}

#endif

//Serial.print("SenseOneCycle(2): ");

//Serial.println(total);

if (total >= CS_Timeout_Millis) {

return -2; // total variable over timeout

} else {

return 1;

}

}