I have been selected to road test the Megger MIT420/2 for the element14 community and this first blog is an introduction to the various elements of the package that has arrived and what I intend to do for the review.

The first item, often overlooked, is the case. For an engineer, such as myself, that travels from site to site, protection of the instrument during transit is extremely important. The meter sells for around £500 in the UK, not including VAT, so damage would be an expensive experience.

The case provided with the MIT420/2 is a 100% plastic blow molded case however, it appears to be very robust and strong and will provide plenty of protection to the meter. The hinge is a molded pin design and looks to be solid and long lasting. The catches are also of a hinge pin design, but are much thinner. They also only open up 90 degrees and could be susceptible to damage if they got caught. Should any damage occur, Megger provide, not only a complete case as a purchasable spare, but also a pair of catches that can be clipped into place of the old ones.

Internally within the case, there is a shaped section for the meter and a pocket for the documentation and CD ROM that arrives with the package. The leads, probes and clips are contained within two open pockets and do rattle around inside the case. They are not likely to cause any damage but my preference is to have the items secured as it reduces the likely hood of loss when working up on platforms and grilled floors and allows items to be easily accounted for when working in clean conditions areas. Over time, I plan to obtain some tool foam to overcome this issue.

The documentation provided with the meter consists of a warranty extension period when ownership of the meter is registered with Megger on their website. Two safety sheets are included, one covering the safety elements of carrying out insulation testing and working on electrical apparatus and a second on the use of fused test leads. Megger offers the latter in both 500mA and 10A HRC fused variants as purchasable accessories.

A quick start guide is also included. This covers the basic functionality of the insulation tester. It appears to be a common sheet covering the various testers within the family, therefore some of the elements within the guide are not applicable to this specific tester.

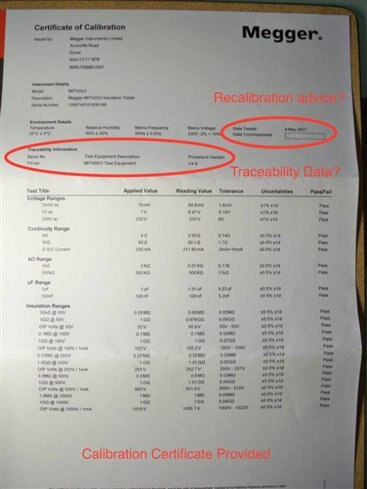

A manufacturer’s calibration certificate is also included within the package. Megger, should be praised for this, the certificate contains full calibration data, with measured values and acceptable tolerances. As I work in an industry that consists of traceability and audits requirements, there are two slight improvements that would benefit me. The first is guidance from Megger over the duration of the calibration period. The certificate is dated for the actual calibration checks and a blank box is on the certificate for the owner to add in the date of ownership. However, no guidance was found on when the tester would be due for re-calibration.

For traceability, the certificate lists the test apparatus used for the calibration, but does not include a calibration date or certificate details for this item. The certificate would benefit from this to meet the full requirements of audit.

All other documentation is contained within the CD-ROM, including a full manual for the meter and also the document ‘A Stitch in Time’. This is the guidance document from Megger on how to carry out the various aspects of insulation testing. It is an excellent document and a good read for someone wishing to know more about the subject. It is a great touch for Megger to include this. For those interested, the document can be obtained by registering on the Megger website.

A set of test leads has been supplied with the MIT420/2 insulation tester.

A control probe lead is supplied with a bespoke connector that plugs into the positive terminal on the MIT420/2. A built in probe is permanently wired to the other end that houses the control button and a built in probe tip, this has a plastic cover that makes the tip GS38 compliant but can be removed to reveal a standard 4mm plug that can be used with other accessories. Megger have included an insulated probe tip as one of these accessories.

A pair of leads with built on probes are also supplied, one red and one black. These plug into the insulation tester outlet terminals but neither connects to the control button terminals. The probes have a standard 4mm connection plug for accessories however, the safety shroud is bespoke to Megger and means that only their accessories can be utilised with the probes. Megger have provided a pair of crocodile clips and short probe tips within the package but other third party clamps and probe tips will not always fit. I hope to expand on this aspect during the testing phase of the review.

This isn’t much of a problem for experienced engineers that are likely to have other leads and clips within their toolbox to cater for unusual connection requirements that may arise on the odd occasion. Less experienced or those just setting out may find themselves caught out.

As the tester will take standard 4mm safety leads, a third party set of leads can easily be used when required. However, the quality of the leads must be right. The insulation tester has an output of up to 1000V and can read up to 200 gig-ohms. At this level of insulation values and voltages small current leakage between the positive and negative leads can have varying impacts on the insulation reading obtained. This will also be dependent upon the type of testing carried out. The MIT420/2 has the capability to carry out dielectric absorption ratio and polarization index tests. These types of tests can lead to high resistance values, but leakage through poor quality leads would reduce the values obtained and give lower ratio values, giving an impression that the apparatus being tested may need attention or have a fault. Again, I plan to expand on this aspect during the testing phase.

Finally to the MIT420/2 insulation tester itself.

The instrument is from a family of seven testers with varying functionality. Two of the instruments are aimed towards the communication sector and another offers a high voltage output of 2500V DC for more specialist applications. This leaves four insulation testers of immediate comparison. The MIT420/2 is the third in this line of testers offering a capacitance function, a variable voltage output and the ability to save test results. The top of the range instrument adds the ability to download the saved results to a computer via bespoke software and a rechargeable battery option.

This is also an updated series of insulation testers. Compared to the original version, the MIT420/2 offers a variable voltage output and a single resistance measurement function up to 1MOhm that was previously split across two ranges. The voltage measurement function has also been moved to the first position on the rotary switch on the latest design. Although not a recognised testing for dead procedure, it does allow a final check for voltage absence before moving to an insulation testing function and that the circuit has discharged when switching back from insulating testing to the off position. I like this touch as an additional safety feature not present on other insulation testers on the market.

Physically, the MIT420/2 is of a similar size to the Keysight U1461A but weighs around 100g more. Its shape is unique to Megger and is comfortable to hold in one hand, however I found that I could not reach all of the function buttons below the display when holding in one hand.

The MIT420/2 does not have a separate protective boot; the black rubberised coating is permanently fastened to the hard gray plastic case. The display is large and clear, with a combined analogue and digital display. A backlight facility is included that enhances the display greatly for use in poor lighting conditions.

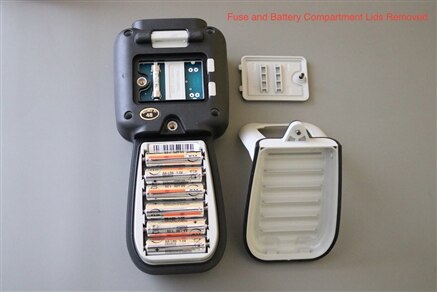

The battery compartment has a separate cover with an integrated stand and is held securely by a single captive screw and a metallic threaded insert giving good durability. There is also a separate compartment that contains a single 500mA HRC fuse for meter protection. Both of the covers have an integrated seal to protect against dust and dirt ingress.

The basic function of the MIT420/2 is selected using the rotary switch on the front of the meter. Optional functions are then selected using the push buttons just below the display. This area also houses the save button to record the current test result to a memory location, the display backlight button and beeper volume button.

Retrieval of the saved records is made by selection of the record function on the rotary switch. The next position on the rotary switch allows for specific records or all of the records to be deleted from memory.

A final position on the selector switch allows for the various instruments settings to be adjusted such as the variable voltage level, timer adjustment and voltage safety cut out level.

Below is a brief description of the functions and how I intend to put them to use;

- Voltage Measurement Function – I plan to test this out whilst carrying out rotor winding resistance and AC Impedance tests that will require measuring both AC and DC volts.

- 100V Insulation Test – This would be used to test insulated bearings in generators and some motors; unfortunately I am struggling to plan this kind of work in.

- 250V Insulation Test – Utilised to test single phase AC circuits, I plan to use this whilst testing out some motors that have anti-condensation heaters installed.

- 500V Insulation Test – This will be the most utilised function for testing various three phase motors and panels.

- 1000V Insulation Test – This will be utilised for testing air circuit breakers that are currently in storage.

- Variable Insulation Test – I plan to use this function to test some generator rotor windings that are DC rated. The variable function will allow me to select a test voltage closer to the working voltage of the winding.

- Timed Insulation Test – Each test voltage has the ability to record a dielectric absorption or polarization index ratio, I aim to use these functions when testing motors and generator rotors.

- Resistance Measurement – I will use this during motor testing to verify phase balance and also rotor winding testing to verify connection resistance for specific tests.

- Capacitance Measurement – Presumably this has been added for single phase motor start / run capacitors and lighting circuit capacitors. This is another function I probably won’t use too much.

This concludes the blog, in the next blog I plan to take a look inside the meter to assess the build quality.

Top Comments