RoadTest: Fundamentals with Multicomp: Show Us How To Solder

Author: shabaz

Creation date:

Evaluation Type: Independent Products

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: I would also consider Knipex cutters. For a soldering station, in Europe I would consider the new Metcal solder station, however it costs more.

What were the biggest problems encountered?: I didn't like the response time for the soldering station. I struggled soldering with the solder tips I could find. A bevel tip was out of stock, so I couldn't try it. Aside from that, no issues! The USB soldering iron experience was very smooth, no issues at all.

Detailed Review:

This review covers a large range of tools! There is a 15-minute video showing some of the tools (in particular an all-in-one 80W soldering iron , a USB Soldering Iron , and an 80W Soldering Station , in that order) in action.

The long story cut short is that I really liked the USB soldering iron, it performed really well for general microelectronics work. The all-in-one soldering iron is pretty good too, ideal for field on-site work repairing control panels and so on, and I wouldn't hesitate to recommend it to friends and colleagues for general repair work, it's quite low-cost for what you get. The soldering station I didn't really like. It didn't feel responsive and I couldn't understand what type of user it would be intended for.

A USB-powered soldering iron can be extremely handy for portable use. This particular one has a straightforward Type-A connector and power requirement that can be met by most mobile phone chargers these days (it is not recommended to connect it to your PC USB port : ). This USB soldering iron operates from any 5V 2A USB source, and therefore offers up to 10W of power – and as is evident from the video, the soldering iron tips can make good use of this power, because the tips have an integrated heating element.

The USB soldering iron kit looks to be of good construction. The USB plug portion is glued shut so I was not able to view the internals, however, all externals look very well made. The iron feels good, has a nice finish, and the attached 140 cm long cable feels reasonably flexible. The soldering tips have an integrated heater, a nicely machined body, and a gold-plated audio plug connection into the (good quality) plastic handle.

The soldering iron visually looks very similar to a JBC iron which I enjoy using. The (again high quality) soldering iron stand has an aluminium base with steel weighting. The supplied ball of brass wool is quite small, but that's a consumable item and you could place a larger ball in there when it is replaced. However, since there is not a standard size, I took a larger ball, and used scissors to trim it slightly, and stuffed it into the stand – problem solved : )

Using the iron with a portable USB Power Bank is easy, just plug and go! There are three user-configurable presets, and preset 'B' was set at 350 degrees C by default, which suits me fine. A single button can be used to switch across presets, and additional buttons are present for further adjustment. There's also an optional calibration adjustment that is possible; if the displayed temperature is incorrect then an offset can be programmed into the iron so that it displays the correct value.

The photo below shows a comparison of the USB iron compared to a couple of JBC irons. In terms of size, the USB iron sits in the middle of the JBC range.

The iron comes with a 1m long grounding cable with an alligator clip on the end, and it's fairly important to use that when powering the iron from any mains-powered USB supply, otherwise, there is a risk of damaging your circuits (this is not a specific limitation of this soldering iron, it is common to all USB soldering irons). Most mains USB supplies will not have the USB metal shell grounded, and a small voltage is likely to be present that could damage (say) MOSFETs and integrated circuits, so an Earth Bonding Point Plug can be used (this is needed for electronics soldering anyway, to provide a ground path from the bench mat and wrist strap; the plug contains a 1 MOhm resistor from the terminals to earth).

In the video review, you can see that I cut off the alligator clip, and changed it to a banana plug which is more convenient.

It's a nice touch that the iron is supplied with a rubber cap to protect the soldering tip, even when it is warm, and a plastic cap to protect the USB plug, but I think it would be a good idea to put it all into a case or storage tube if it will be thrown into a bag.

If I can suggest any improvements to the product, one main one would be regarding the caps, that I wish the USB connector cap was tethered, because it will be easy to lose; the rubber soldering tip cap will soon get lost too. If a storage case was supplied then one could get in the habit of placing the caps in there. Another improvement would be an on/off switch so that the USB connection doesn't need to be removed to temporarily power down, especially when using a portable power bank. These are minor suggestions; in general, I thought it was a very impressive product. It was pleasant to use for low-power electronics through-hole and general surface mount work. I used a bevel-ended soldering tip, and this was fine for through-hole components, connectors and medium-sized surface-mount parts (such as SOIC, 0805 and 0603 sized parts). The iron begins to struggle with very large items, but this is to be expected. The video shows that a copper alligator clip could be soldered, but it took a while for sufficient heating to achieve that.

To summarize, the performance is generally good, especially with my preferred soldering tip selection (bevel tip, Multicomp MP740611, costs around £12 + tax), one can easily forget that it is USB-powered while soldering with it. The controls and display are straightforward and sensible, and it is all constructed to a high standard, including the compact soldering iron stand. This is a great product overall, and I enjoyed using it and will continue to use it. It costs around £55 plus tax, which seems a reasonable price for the entire set of soldering iron and tip, rubber protective cap, stand, cleaning wool, and USB-to-alligator earthing cable, although I wish there was a set for £45 with no included soldering tip, so users could just buy the (in my opinion) better bevel tip instead of the supplied pointy conical tip.

I have not used an all-in-one direct mains-powered soldering iron for several years! They are ideal for quick in-the-field on-site soldering work where it's not feasible to carry an entire soldering station along. Such irons can also be useful for beginners in electronics when getting started and when cost and storage space is a concern. Really these irons are more suited to through-hole work (or some larger surface-mount work if no other tool is available), soldering wires to large connectors, and so on. Still, for learning electronics, I went through several all-in-one soldering irons, from teenage to beyond college, only purchasing a soldering station well into my career (at work I had access to a soldering station).

The photo below shows my old all-in-one soldering iron, alongside the new Multicomp one.

The three tactile push-button controls on the iron are straightforward; the up/down buttons are used to select a temperature (indicated with blue LEDs) between 350 and 480 degrees C (660 to 900 degrees F), and the third button turns the iron on or off. The selected temperature value is retained after power-off.

The soldering iron comes with a tiny stamped metal iron stand that isn't really fit for any purpose, but that's typical of many all-in-one irons.

The soldering tips hug the internal 4 mm diameter ceramic heating element; it's a smooth fit, not stiff, nor with any play, so I was expecting heat transfer to be reasonable. Incidentally, the circular metal plate (visible in the photo below attached to the plastic handle) does get hot, although it didn't burn me so far!

A minor point is that the LEDs are recessed within the enclosure, which makes them awkward to see unless looking dead-on at them (you can just about see an LED illuminated in the photo below).

More of an issue is that the iron body is too smooth, there are not many parts of it that can be used to prop it on any stand. Again this is a problem common to many all-in-one irons, that they are not designed for use with a proper stand, they are used on the go and not left switched on for long periods that would necessitate a stand. One workaround that I used for years, is to leave a blob of blu-tack (repositionable putty) permanently attached on the side of the iron, and use that to adhere the iron to the desk. It would be nice if the iron had a slightly flat surface for this.

The soldering iron comes with a short stiff piece of plastic tubing to protect the tip during storage, but really some more protection may be needed if it will be placed in a tool case or bag. The ceramic element will be delicate so you don't want anything hitting the soldering tip hard from the side.

Aside from the minor points like the lack of a proper stand and storage case (neither of which I expected anyway), I liked the iron. It is better than my old all-in-one soldering iron that has a poorer, less responsive tip attachment method and awkward screw-set temperature adjustment, and the Multicomp iron costs a lot less too (around £33+tax), and the soldering tips are extremely low-cost, and the tip selection is not bad for an all-in-one iron (the selection of tips is not appropriate for general electronics prototyping, it is more suited for on-site work, for instance repairing machine control boards).

I think this is a good iron as far as all-in-one on-site repair work irons go. I would score it approximately 7 out of 10 since it performed pretty well but I'm unclear about how rugged this may be without a case, and it is too easy to touch the hot metal plate area. This score is higher than what I would give to my old Antex soldering iron. I'd have no problem recommending this Multicomp iron to colleagues looking for a good general-purpose soldering iron for home repair work too.

Soldering stations are generally the most flexible option for handheld soldering, usually available with a selection of soldering iron handles and soldering iron tips. They are often very configurable, to reduce inconsistency in production scenarios. The Multicomp Pro soldering station consists of an 80W base unit, a soldering iron handle with a DIN plug attachment to the base, and an all-metal stand. As with the other irons reviewed above, it comes with a single installed tip. The total cost is about £85+tax. Additional soldering tips are extremely low-cost (less than £2). The soldering station is originally made by Atten, so there is the possibility of finding a wide range of affordable spares if any items were to ever get damaged.

The iron handle has a comfy soft grip area, and the connecting wire is very flexible. The strain relief feels flimsy but everything with this iron seems easily repairable if it ever came to that.

I liked that the power on/off button is at the front : ) some soldering stations place it at the back. All the buttons are tactile and the (approx.) 2 kg base station does not slide on the desk when any buttons are pressed.

The iron stand is well constructed but I didn't like that it comes with a bacteria-friendly sponge when the world has moved to metal wool for cleaning soldering tips. Fortunately, a wool holder is low-cost. I discarded the sponge and placed a magnetic sheet (pulled off a fridge magnet) into the sponge location, to repurpose that area to store soldering tips instead.

In use, I get the impression that heat transfer is not as responsive as the other two irons. With fine conical tips, I could not solder through-hole parts very well (this is noticeable in the video recording). Unfortunately, I could not obtain a small bevel tip, perhaps that would have improved things. There is an argument that the correct soldering tip should be used for through-hole, but frankly, times have moved on, and modern irons should be able to accommodate different soldering targets, within reason, even with non-optimal soldering tips, because it is impractical to keep swapping out soldering tips. My normal-use soldering iron is merely 20W maximum power, and a single bevel tip gets used for 90% of the time, for general surface-mount and through-hole work except for the very large connectors.

There is a wide range of low-cost soldering tips available for this soldering station system, but the range is not as comprehensive as other soldering stations, and this is a problem – for example, I cannot find any suitable tip to solder the RF connectors used on this RF switching project (admittedly this is a very specific scenario that one may not come across all that often).

Personally, I cannot see a reason to purchase this soldering station unless (perhaps) it is intended for production use for low-tech products assembly (such as soldering on speaker connections or battery clips all day long) or perhaps a basic repair shop use-case, in which case this soldering station is fine, low cost and repairable. From a design engineer/prototyping perspective, this is not the right tool (perhaps it was fine 10 years ago, but times have moved on). From a student perspective, I think it is a much better idea to get the USB soldering iron instead and then you'll experience the benefits of integrated heater technology at low cost, and be able to use that for all manner of electronics projects throughout your course.

The wire cutters have a plastic sticky-feeling grip area and are made from stamped sheet metal. I prefer forged tools. The wire cutters, for me, did not seem to be of good value, but after trying them, I was surprised that their performance is not bad. However, I still wouldn't recommend them for a few reasons. The cutters have a piece of spring wire to keep them in the open position, but the action is very sluggish even after trying to bend the wire to apply more force.

They seem overpriced at £14+tax, and although they worked fine, for a few pounds more you can get something better like Knipex Super Knips 78 03 125 ESD at £18+tax. I tested by cutting 1.6mm diameter copper wire (this exceeds the 1mm rating of the cutters) a few times and it didn't seem to dull the edge of the Multicomp cutter, at least visually. I also tried cutting tin-plated stranded earth wire as shown in the photo below.

Despite the Multicomp tool cutting well, the Knipex Super Knips is rated for 1.6 mm soft wire, so perhaps that is the better choice on a budget.

If you're a student on a very low budget, this item is fine. Otherwise, for all other users, you may want to spend more. The reason is, this type of Helping Hands product is awkward to use and doesn't hold things very well without a lot of effort. The helping hands with magnifier are very low cost (about £6+tax) so is very student-budget-friendly.

A suggestion for an alternative could be to examine the PanaVise catalog for work holding/clamping.

Incidentally, for work holding, there are PCB holders at low cost such as Velleman VTHH6 which I have not tried. For holding some items, you could assemble your own helping grippers, such as the one demonstrated in the video and shown in the photo below.

In summary, the helping hands are a basic tool but are very low cost and value for money if there is no other clamp/gripper available.

I thought the solder tip cleaner was very good. The solder tip cleaner consists of a weighted round container with a soft base, and it comes with brass wool as a consumable item (you won't need to replace the wool for years unless you're into a heavy amount of soldering!). I actually already have the same product, but I replaced the brass wool with steel wool – it might be more aggressive, but I have not seen any noticeable impact to my soldering iron tips for several years). In any case, the brass wool is fine, it does its job. With the steel wool, I feel I don't need to twist the soldering iron tip as much to clean it up, but I may be imagining it! In summary, at £6+tax, it is a no-brainer to purchase this, for any soldering use-case, if you're currently using damp sponges.

The container has a shaped wire piece that can be swung up for propping some types of soldering irons, but I used a separate soldering station with its own stand, so I didn't need to resort to that.

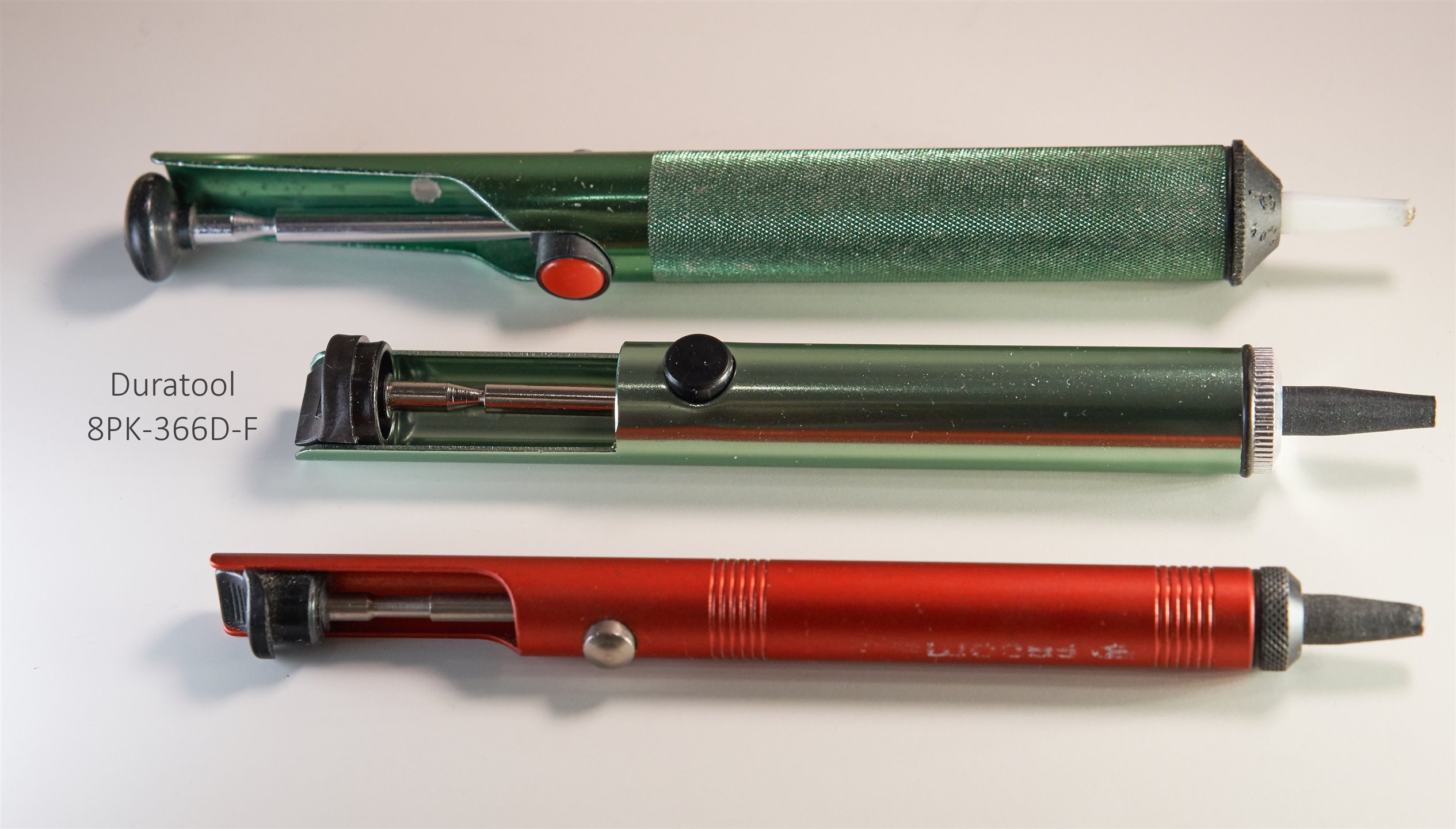

There are several types of desoldering tools, but the plunger style, such as this one, is a great all-round tool to have. It doesn't cost much (£5+tax) and can extract the majority of solder easily, although you might need to follow up with desoldering braid or wick. I already have a couple of similar desoldering tools. The Duratool product is medium-sized, and the suction was fine when I tried it.

However, I have compared the Duratool model with the existing desoldering plunger tools that I own, and they look similarly constructed, on the outside, mostly aluminium and steel construction. On the inside, things can be different.

The desoldering tool on the right side of the photo has no visible spring, I think it is better constructed that way, but it's not a big deal to clean out the spring on the other products. I'd recommend not purchasing a desoldering tool that is very small or thin such as the red one, because the piston seal can become sticky over time, no longer rapidly sucking up any solder. The Duratool product seems to be of a more sensible size.

As a result of the comparison I'd expect the tool to be reasonably reliable for at least a few years, so again this tool is almost a no-brainer to purchase. I liked that the plastic nozzle is ESD-safe too.

This was an interesting RoadTest, trying out a variety of tools for circuit prototyping.

I liked the solder tip cleaner and the desoldering tool, I think both items are worth recommending to anyone who already does not have such tools, and they should both provide years of service, for beginners, students, and professionals alike.

The Helping Hands product is kind of an essential tool if you have no other clamping/work-holding methods. It is low-cost, so it is ideal for a beginner on a budget, but you'll soon outgrow it.

The wire cutters cut well, but are more expensive than they ought to be. If you're on a severe budget, consider just buying combination pliers, they are often cheap and can cut close enough for beginner project work. For all other users, I think it's worth spending a bit more on the wire cutters, for instance, the Knipex Super Knips 78 03 125 ESD product costs just a few pounds more and has a better wire cutting diameter rating.

I tried out all three soldering irons – the soldering station, the USB soldering iron, and the all-in-one iron, and the video hopefully provides an indication of what they are like to use!

I have mixed feelings about the soldering station. It is low cost compared to other soldering stations that are out there, and the consumables are low cost as well, it has a fair selection of soldering tips, but it has average performance and the tip selection will still not meet the needs of all design engineers or those creating prototypes. For those users, they would be better off spending more on a higher-end soldering station. For student users, I don't see why they would buy this soldering station when the lower-cost USB soldering iron would meet their needs. I think the soldering station would be an adequate replacement for anyone using an ancient soldering station that has failed and needs an upgrade if their requirements have not changed over the years. The soldering station may also be fine for (possibly) low-tech production or repair use.

Of all the soldering irons that were reviewed here, for me the surprise star was the USB soldering iron. Going into the review I had not expected that : ) The USB soldering iron performs so well it is easy to forget it is not a mains powered iron for most of the time. It is a polished product, looks well made, and works with any 2 amp capable USB power source. The soldering handle is very comfortable too. If you're buying this iron, I'd recommend also purchasing the bevel soldering tip and a larger ball of tip cleaning wool than the supplied one.

The all-in-one soldering iron performs very well and is more suited for beginners to electronics who do not want to spend too much on an iron, or for general home repair or on-site work. This soldering iron is suited for through-hole work and for assembling wires/terminals or connectors, it is not suitable for surface mount work. This is the soldering iron I would recommend to friends who are not into microelectronics but are technically competent enough to do occasional soldering work or repairs, and I think the iron is a great choice for that.

I hope this RoadTest review was useful, please let me know if you have any comments or questions. Thanks for reading/watching!

Top Comments

Nice demo and experience bringup. The images are pleasing,.... :)