RoadTest: NI Thermocouple Measurement Kit - Industrial Sensing

Author: Chrisrad

Creation date:

Evaluation Type: Test Equipment

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: Pico Technology PicoLog USB TC-08

What were the biggest problems encountered?: My biggest problem was installation of the software due to network restrictions on our corporate LAN. This could be avoided by installing from a CD and using an open network connection.

Detailed Review:

Introduction

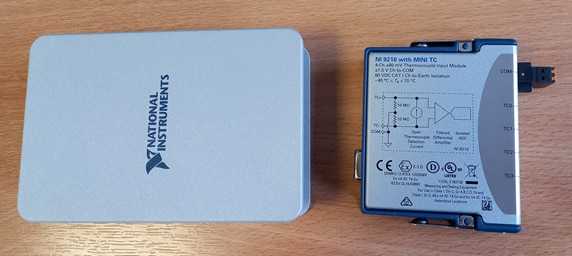

This is a RoadTest review of the National Instruments “C” Series Temperature Input Module 9210 for the CompactDAQ and Compact RIO data acquisition systems. There are several variants of the input module, featuring different input connection types for thermocouples and also variants for resistance temperature probes (RTDs).

The temperature input module was supplied for testing with a single slot Compact DAQ Chassis with USB connection, (Model 9171) as shown in the photos above, but the input module can also be fitted into a wider chassis racks up to 14 slots wide for larger acquisition and control systems.

The National Instruments ADQ systems feature a wide range of input modules which are compatible across the range of chassis.

Out the Box

The unit was well packed and a professional looking piece of kit, complete with 4 “K” type thermocouples with pre-wired plugs already fitted and ready to use. The module is a very rugged looking industrial piece of kit. The chassis holder is very business like and “industrialised” with a nice diecast aluminium housing. The input module is a pleasing and secure fit into the holder with well engineered clips.

The module sits on rubber feet for desktop / laboratory bench use or there are 2 “keyholes” in the back of the case which would allow fixing to a bracket for a temporary or permanent installation

Software Installation and First Startup

Several pieces of software are included free with the NI data acquisition hardware. These include NI-DAQmx, device drivers and DAQExpress. These were not shipped with the bundle and so I first had to make an NI.COM user account, then log in to download them.

This step proved a little problematic as the normal online installation could not pass through our corporate firewall. Most corporate users will probably face this same annoyance because administrator rights are normally required to install software. There was an option to request a install CD from NI, and I would recommend this in future.

In the end, to circumvent the corporate firewall, I had to use the “ISO” images to install. These are VERY big files (up to 10 Gb each), so you need to make sure that you have plenty of available disk space to download and THEN unzip.

Once the software was installed, I connected the input module via USB and the device driver installed automatically. The software then attempted to register over the internet, but this step failed as AGAIN I needed ADMINISTRATOR level support to get things installed through the LAN firewall.

NI-DAQmx

This provides the device driver and other support software for the module. Whenever the CompactDAQ is plugged into a USB connection, the drivers recognise it and automatically open the NI Device Monitor (below) where you can select the application you want to use.

Applications for the NI Compact DAQ

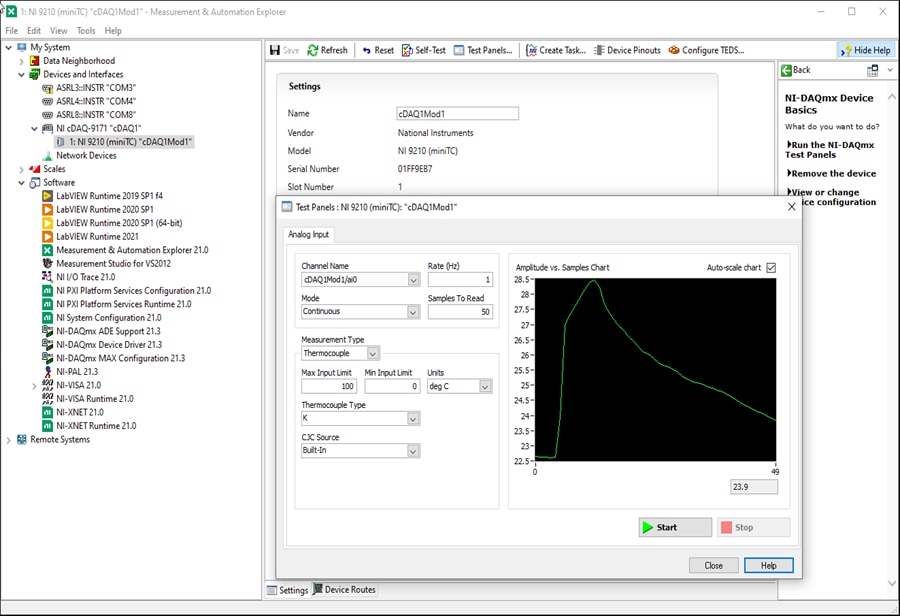

The NI Measurement & Automation Explorer is know as “MAX”. This is a configuration type utility which monitors hardware and software

The MAX app was fairly obvious and I quickly managed to activate a thermocouple in one channel and take some “Test Panel” measurements at my desktop

The screenshot below shows just how much software is associated with the unit and helps to explain why the distribution files were so big and why the software took so long to install.

DAQExpress

This software caused me quite a lot of problems, I could not get it to run as it kept constantly asking for online access, however our corporate firewall blocks this. So once again I failed at “self-installation” because of being dependent on having a system administrator available to help me. I then moved onto a 4G tethered connection to a 4G mobile phone, this seemed to install the DAQExpress, however on the first few attempts the program crashed!!

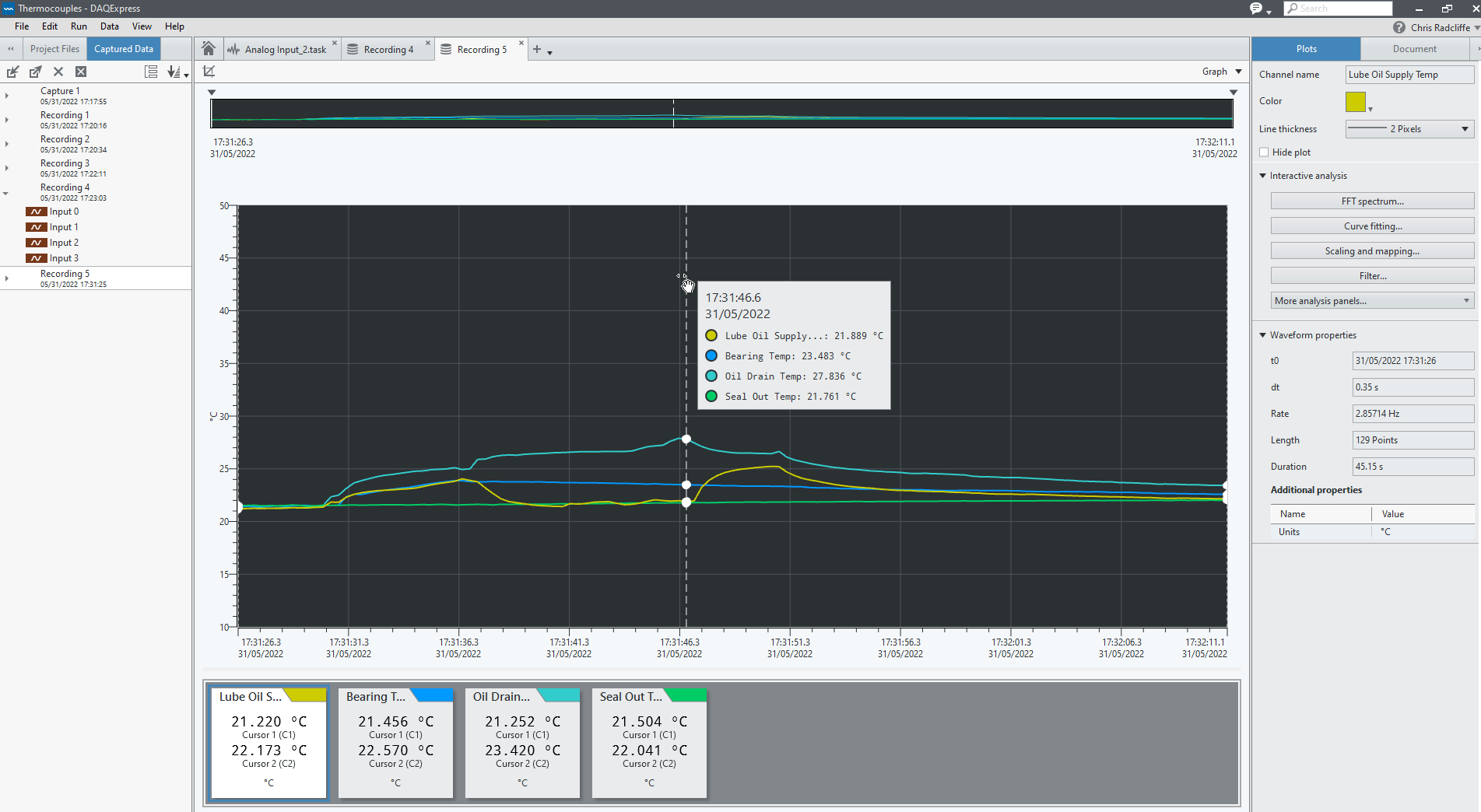

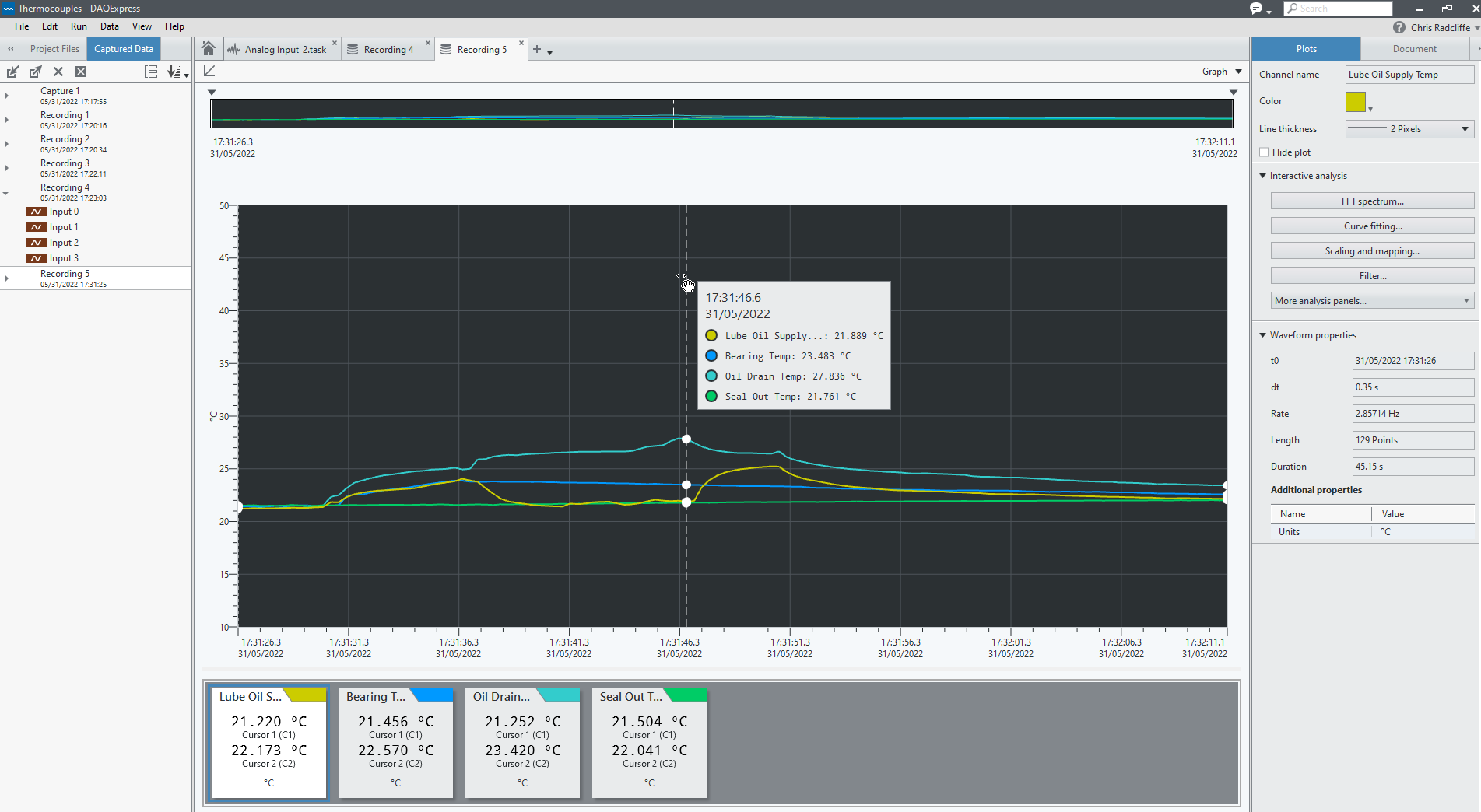

Eventually I got it working to find that it is a fairly intuitive program with a nice interface. Data shows on the screen while it is been collected in a “rolling” type display and at the same time data is recorded in a log file. Recorded data can be re-loaded for examination and further processing options are available including some FFT, scaling and filter which is not really applicable to temperature measurement but would be useful for dynamic pressures, loadings, acceleration and vibration type measurements using other NI input modules.

Sample rates can be set as fast as several Hz, or periodically as required and number of samples collected can be defined by overall time or sample count. Sampling can be started and stopped by setting trigger levels on various signals, but I could not find a way to start logging at a specific time/date in the future which is a feature which I would like to be able to use.

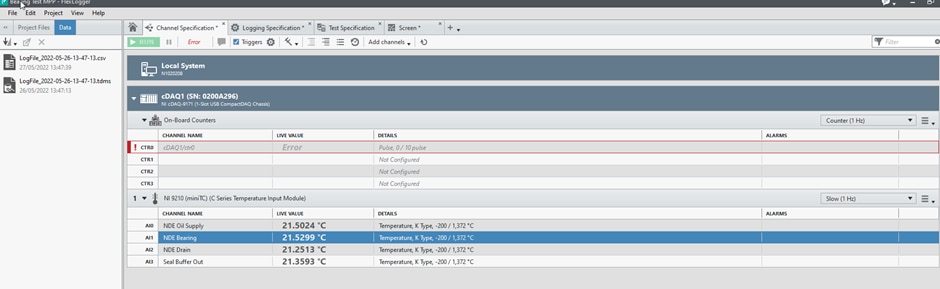

The screenshot below shows an example of the DAQExpress front-end which is clear and simple.

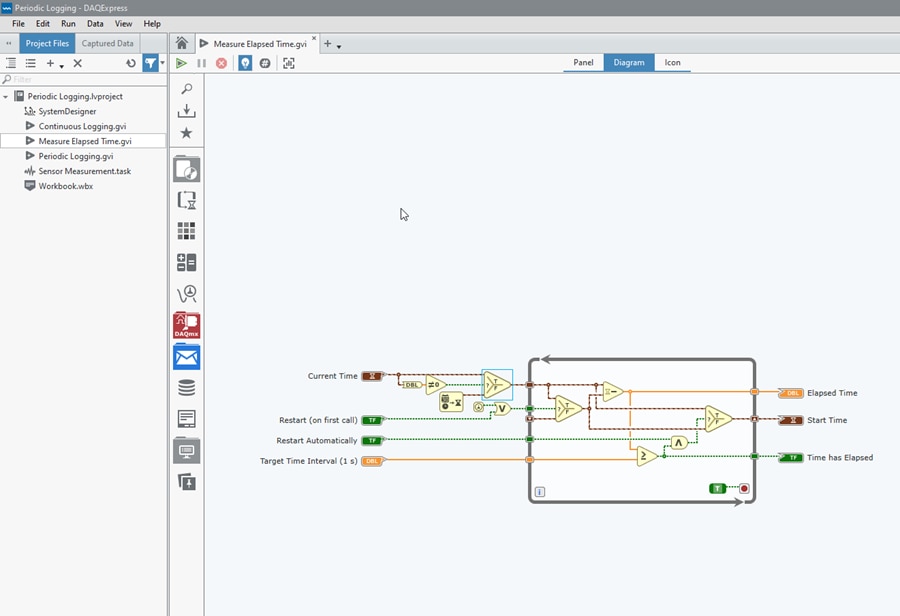

DAQExpress also includes a basic LABVIEW functionality which allows customisation of the acquisition programs, or writing your own from scratch. There are several examples of LABVIEW control code including handling real and elapsed time variables, so it should be possible to customise my own delayed start logging – this will be a homework project for me when I find a bit of spare time!

There is a nice example of programming this NI Thermocouple module using LabVIEW in another RoadTest by neuromodulator at Temperature Control with LabVIEW

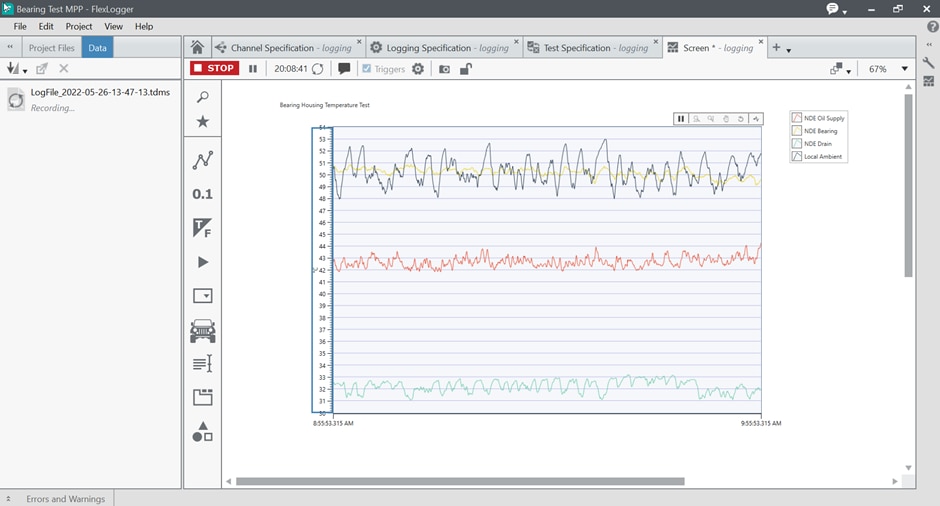

FlexLogger

As part of the Road Test I was also provided with a trial version of the FlexLogger program. FlexLogger is a licensed software application available on either an annual subscription basis (around £500 GBP) or as a perpetual license for £1300 GBP. I managed to install this trouble free using a 4G tethered connection.

FlexLogger is a pretty fully featured “logger” application, although I am reviewing just the temperature module, the FlexLogger software can also be used for logging signals coming from any DAQ module, such as analogue voltages, loop currents etc.

The FlexLogger looks similar to the DAQExpress, and I guess they are both based on LABVIEW in the background. It is very simple to use, there are 4 main tabs across to the top, to set the input channels, the logging specification, such as sampling rates, start and end conditions etc and lastly a visual screen which shows the input values in real time as a “MONITOR”.

Input channels can be thermocouple millivolts, as in the case of the NI-9210, or voltage and current inputs from a very wide range of sensors with scaling directly into engineering units. All channels can be setup to provide output alarms or other triggers depending on level settings if required.

I setup my test to monitor the bearing temperatures on a very large (4 MW power) industrial pump on our factory testbed. The 4 channels were set to monitor the lubricating oil supply temperature, the bearing temperature and the oil outlet temperature as well as the temperature of the pump seal.

Once the program is running the “screen” tab shows the current input values in a “MONITORING” sense, but these values are not recorded until logging is enabled, this can be done manually, or automatic based on conditional threshold values of the signal, or based on time limits. I wanted to start a test the next morning and so selected a logging start time so that the logging would start automatically before the machine started running, this is easy to do in the “logging specification” tab.

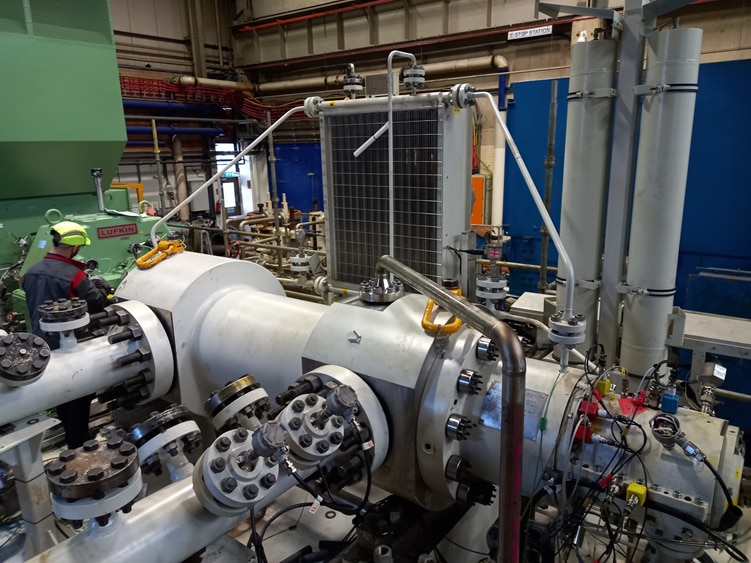

This is the large industrial pump which we are testing.

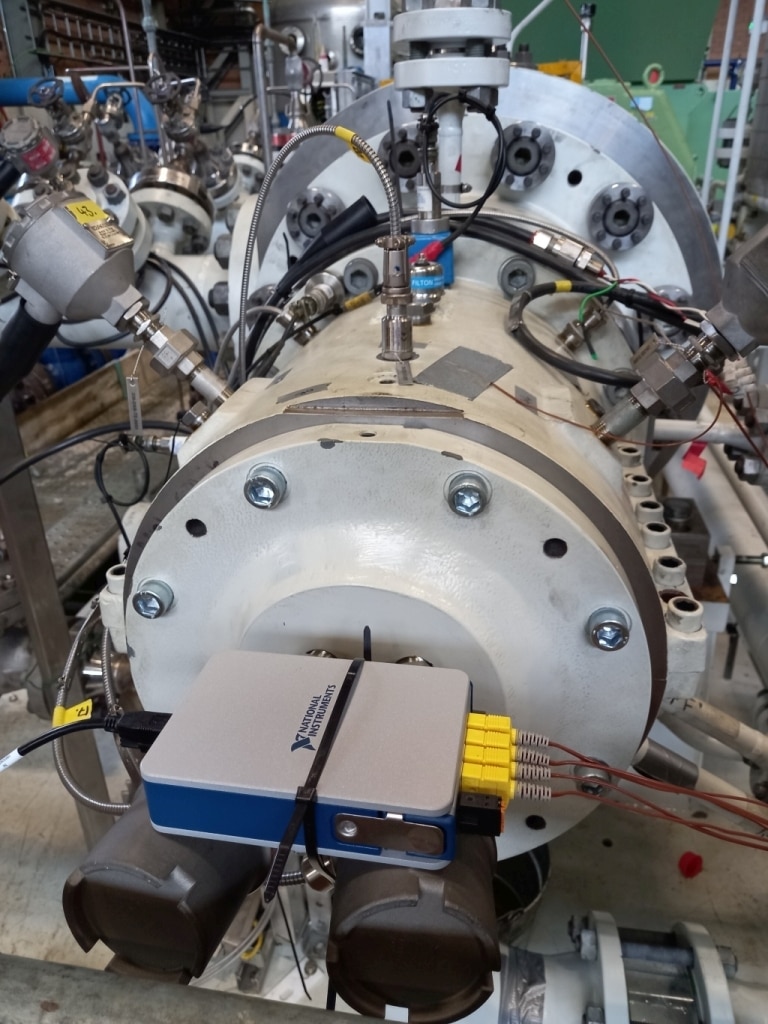

And below shows the NI-9210 Compact DAQ temporarily installed at the non-drive end bearing housing with good old zip-ties! The unit is rugged and industrial enough to stand up to this kind of use.

I setup the system the night before and could confirm that everything was working correctly with the monitoring screen. The unit started logging perfectly the next morning just as required.

Logging goes to a proprietary file format “tdms” but can also be saved, or easily exported to .CSV as required. From a CSV file I produced the following test plot using “GNUPLOT”, my favourite graphing and data manipulation program

Conclusions

Summary

A very nice piece of quality hardware, but I feel it was slightly let down at the start by troubles I had installing the large suite of software.

Once all the software was installed and settled it then proved to be very easy and intuitive and quick to use. It is a bit of a “sledge hammer to crack a nut” for monitoring just 4 channels of thermocouples but I can see that with such a high degree of customisation and integration it would certainly come into its own as part of a much larger multi-channel, mixed signal acquisition system where all the features could be fully utilised.

My advice would be to install from a CD and using a PC with free access to the internet.