RoadTest: Test and Review the Nordic nPM Fuel Gauge Board

Author: dougw

Creation date:

Evaluation Type: Development Boards & Tools

Did you receive all parts the manufacturer stated would be included in the package?: True

What other parts do you consider comparable to this product?: I don't see any comparable products on the market, especially considering the powerful hardware/software integration.

What were the biggest problems encountered?: The system refused to profile a battery when I tried to use a file name (I used a part number) with illegal characters in it - pretty trivial issue, but it stalled me for days.

Detailed Review:

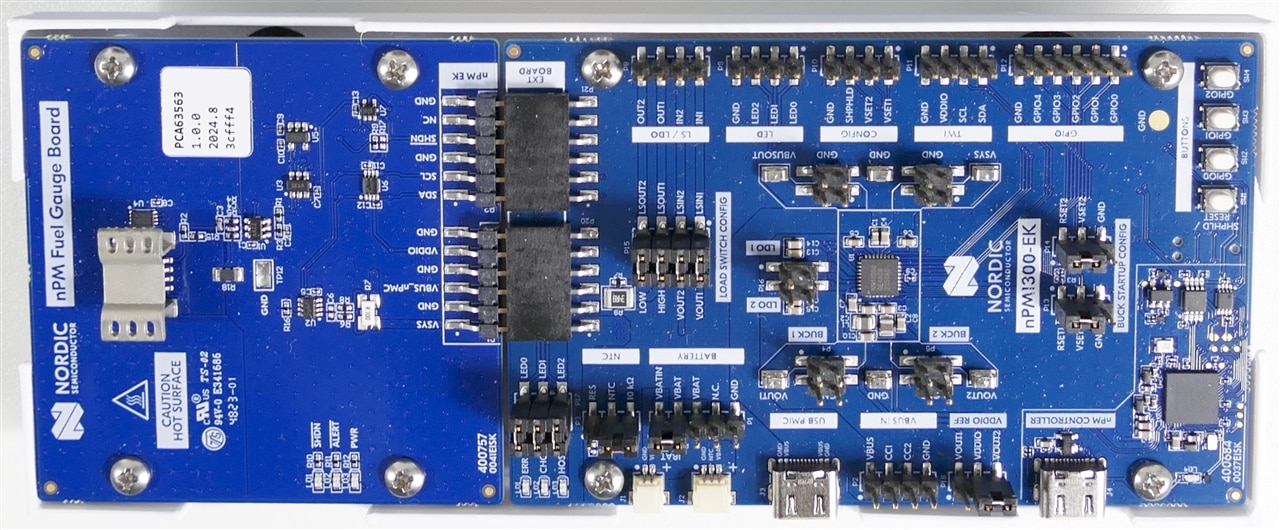

This is a road test of the Nordic Semiconductor nPM Fuel Gauge Board, shown on the left above, plugged into an nPM1300 Evaluation Kit. This Fuel Gauge Board adds a constant current load capability to the power management system. Specifically the Fuel Gauge Board is intended to be used to discharge batteries during the process of characterizing battery discharge curves. Both the nPM Fuel Gauge Board and the nPM1300 Evaluation Kit were included in the road test kit which is important since the Fuel Gauge Board is designed precisely to work with the nPM1300 Evaluation Kit. I wanted to do this road test because together these modules provide the ability to characterize Li-Po batteries for capacity. I have quite a few Li-Po batteries of various sizes and ages and I want to know how well these old batteries perform relative to their published specifications. Some are at least 12 years old, but none have ever been used.

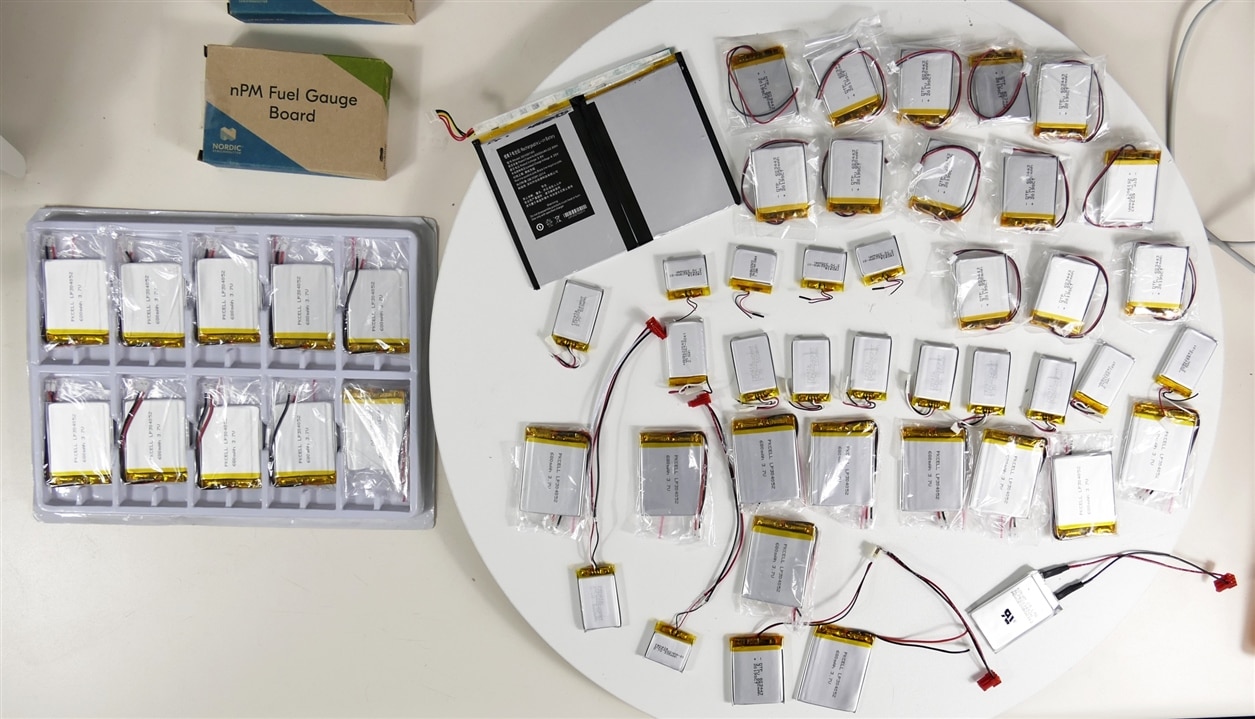

Here is a picture showing the batteries:

Although this road test is about the nPM Fuel Gauge Board, I have to mention some features of the nPM1300 power management IC (PMIC) and its evaluation kit (EK).

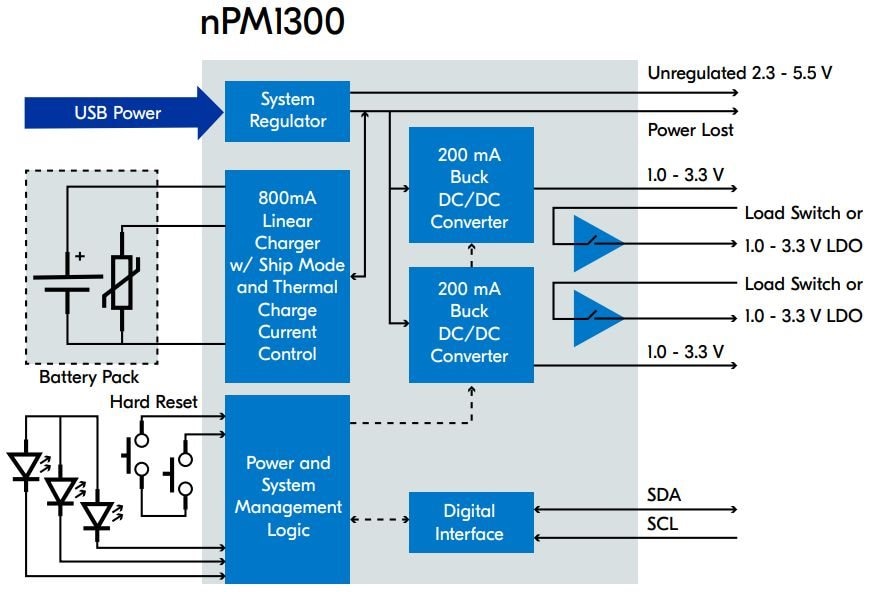

The nPM1300 is an unusually capable PMIC featuring

I have never seem a PMIC with such an extensive feature set. Here is a block diagram:

There is significant complexity and configurability to set this chip up for a specific application but fortunately Nordic Semiconductor provides an "nPM PowerUP" software application that allows graphical configuration of all aspects of the PMIC and even allows configurations to be exported for use in target applications.

The Evaluation Kit provides excellent access to all signals and works with the nPM PowerUP software to test any configuration.

The evaluation kit and fuel gauge board along with the nPM PowerUP software are so capable, they can be used as a complete instrument for my application, among others.

Here is an unboxing and setup video introducing my application:

Battery testing could not be considered an exciting spectator sport, but this guy found it amusing...

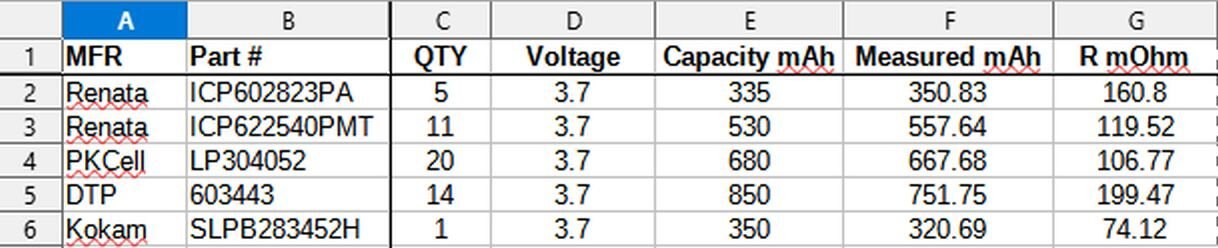

This table shows that the real battery capacity can vary from what is written on the battery. I noticed in this small dataset that the the older the battery was, the lower its capacity was relative to the nominal capacity specifications.

It is good to know that even the 12 year old batteries still perform at least close to their rated capacity.

My time with the nPM1300 EK and Fuel Gauge was a bit of an adventure. I had initially tried using a battery part number as a profile file name and spent a day trying to figure out why the software application was refusing to start. Fortunately Eirik Slettahjell ( the Technical Product Manager for PMICs at Nordic Semiconductor) clued me into the fact that I couldn't use illegal characters. Learning from this type of misunderstanding is why road tests are useful.

Another issue I had was my computer rebooted about 20 hours into my first battery profile which terminated that run. I think Microsoft decided to install an update. The documentation is clear that the computer must run for the whole run, which can be a couple of days long. After that I plugged in my Cyber Chicklet to make sure the computer never went to sleep. This worked perfectly and I successfully captured weeks of data - Cyber Chicklet scores again!

The battery profiling software has the ability account for the way temperature affects the discharge profile, which make its "fuel gauge" much more accurate than other methods. I don't need this for my application, but it is a pretty unique and powerful feature of the system that I will keep in mind for future applications.

If the current sink was programmable, it would open up even more applications for these modules.

The first thing I accomplished was learning a lot about the amazing nPM1300 PMIC and the comprehensive tools that Nordic Semiconductor makes available to streamline development of custom applications.

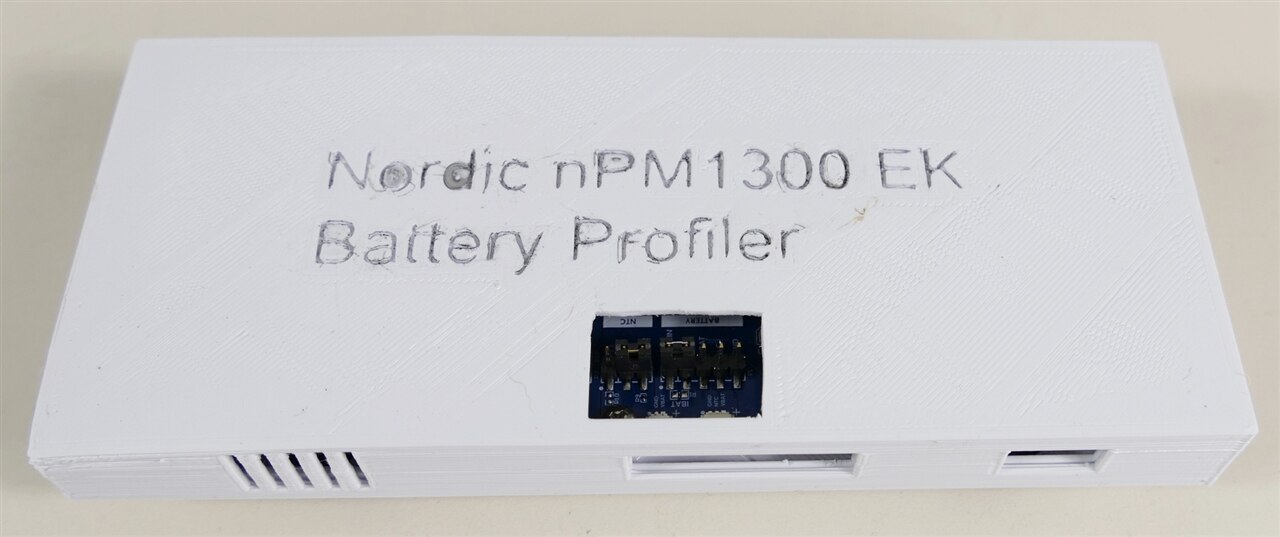

I used the hardware modules and software tools as-is, without needing to do any electronic or software development,.to implement a complete battery profiling system. I designed a 3D printed chassis to turn the setup into a complete instrument that I can use whenever I need to profile batteries, or indeed test other applications of the nPM1300 PMIC.

I was able to properly characterize battery capacity of 5 different types of Li-Po battery, which was one of the primary goals of the road test that capability and made my road test a complete success.

The system works well and I like the way it works, so these quibbles should not be construed as reasons to deter anyone from acquiring and using these products.

They are just notes that might be used to improve the product(s).

These issues are not serious drawbacks, and some of them may be just me missing some documentation or not being familiar enough with the system yet. I am listing them partly to remind myself to look for existing solutions or work-arounds.

A 3D printed cover turns the system into a battery profiler instrument.

The nPM1300 is a fantastic PMIC with a powerful and amazingly extensive feature set that shrinks a lot of functionality onto a single low power chip. I am happy that I got a chance to learn about its capabilities and I am very happy that it can characterize batteries as I had hoped.

The software is comprehensive and extremely useful. It saves a large learning curve and dramatically reduces the time needed to implement tailored solutions.

If you want to take advantage of the great feature set of the nPM1300, these evaluation kit modules will make your life a lot easier and get you to a working solution much faster.

I would like to thank Nordic Semiconductor and elemet14 for sponsoring this road test - I learned a lot and ended up with a useful instrument.

Links: