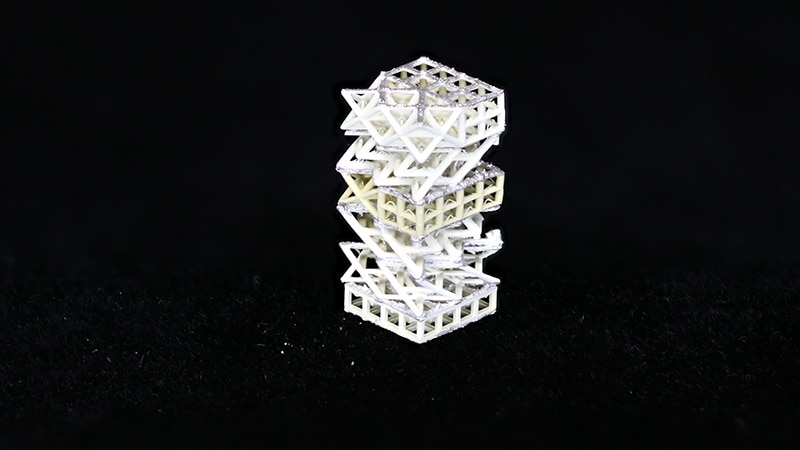

These 3D-printed robots are capable of propulsion, movement, sensing, and decision-making. (Image Credit: Rayne Research Group/UCLA)

UCLA engineers recently developed a novel design strategy and 3D printing technique, allowing robots to be created in just one step. With this breakthrough, engineers can produce a robot's required electronic and mechanical systems via a 3D printing process for engineered active materials with multiple functions. The resulting printed bot can then perform propulsion, movement, sensing, and decision-making.

These materials contain an internal network of sensory, moving, and structural elements and move autonomously via programmed commands. The robot still needs power, so a small external battery needs to be integrated.

"We envision that this design and printing methodology of smart robotic materials will help realize a class of autonomous materials that could replace the current complex assembly process for making a robot," said Xiaoyu Zheng, an associate professor of mechanical and aerospace engineering at UCLA. "With complex motions, multiple modes of sensing and programmable decision-making abilities all tightly integrated, it's similar to a biological system with the nerves, bones and tendons working in tandem to execute controlled motions."

The engineers used both an onboard battery and controller to test out the autonomous robots, which measured the size of a fingernail. Their new approach could introduce new designs for biomedical robots, including tiny swimming robots emitting ultrasounds while autonomously navigating near blood vessels in the human body for drug delivery. Additionally, the bots can maneuver dangerous environments. For example, a tiny robot swarm fitted with sensors can access tight spaces, observe threat levels and locate trapped people in rubble from a collapsed building.

Compared to traditional robot development processes, the UCLA technique relies on the piezoelectric metamaterials, which change shape and move in response to an electric field. It can also generate an electrical charge due to physical exertion. While these materials and their functionalities aren't new, they possess motion range and distance traveling limitations. A connection to gearbox-like transmissions is also required so that it can move as intended. In comparison, UCLA's robotic materials are made of piezoelectric and structural elements that quickly bend, flex, rotate, expand or contract.

These 3D-printed piezoelectric materials can quickly bend, flex, twist, rotate, and contrast. (Image Credit: Rayne Research Group/UCLA)

Additionally, the team revealed a methodology for users to design models and print the materials onto a robot. "This allows actuating elements to be arranged precisely throughout the robot for fast, complex and extended movements on various types of terrain," said the study's lead author Huachen Cui. "With the two-way piezoelectric effect, the robotic materials can also self-sense their contortions, detect obstacles via echoes and ultrasound emissions, as well as respond to external stimuli through a feedback control loop that determines how the robots move, how fast they move and toward which target they move."

So with the technique, the UCLA team developed three bots that demonstrated various capabilities. One robot maneuvered around S-shaped corners and randomly placed obstacles. Another one escaped from a contact impact. Lastly, the third robot walked on rough terrain and slightly jumped.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell