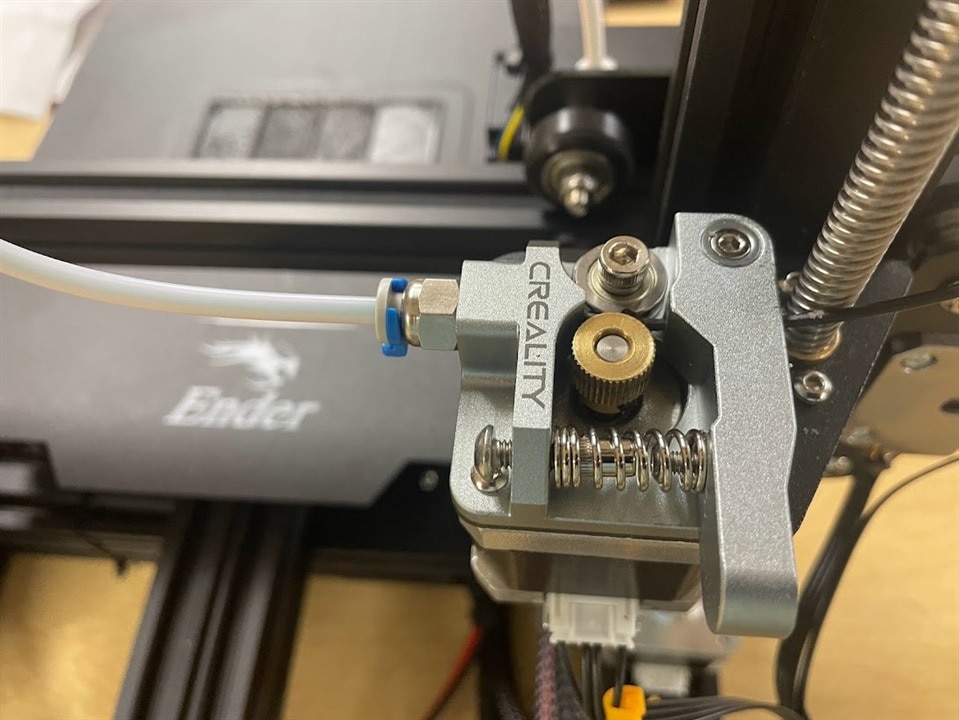

Hi folks, I have an Ender 3 Pro that I bought about a month ago. Stock machine. I have successfully printed using PLA and PETG filament initially. I am using stock settings for PLA and PETG in Cura on a Linux machine for slicing.

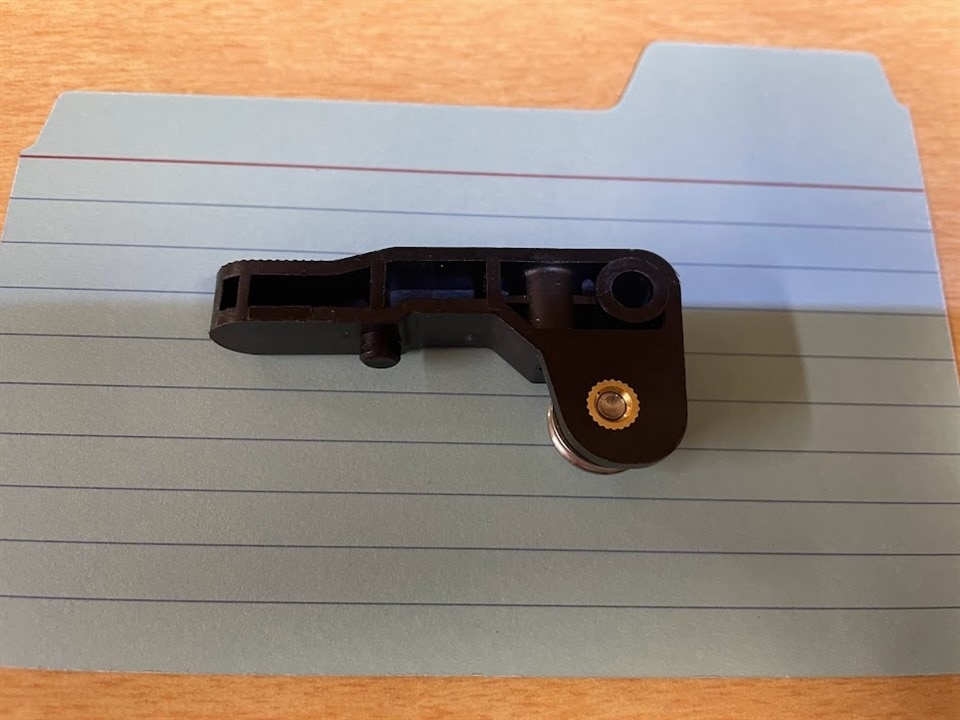

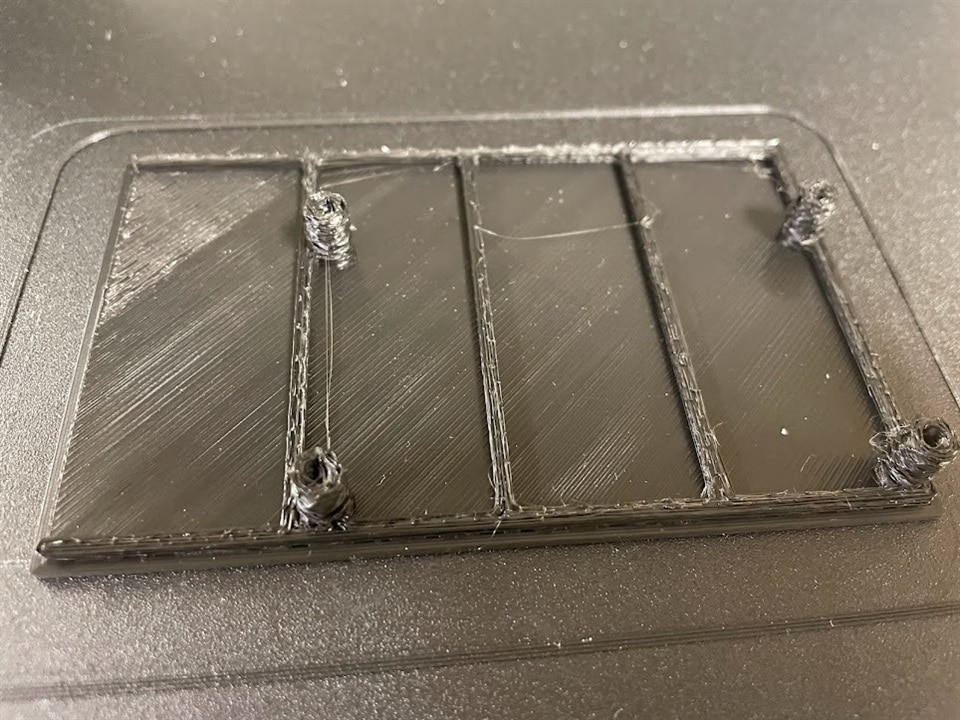

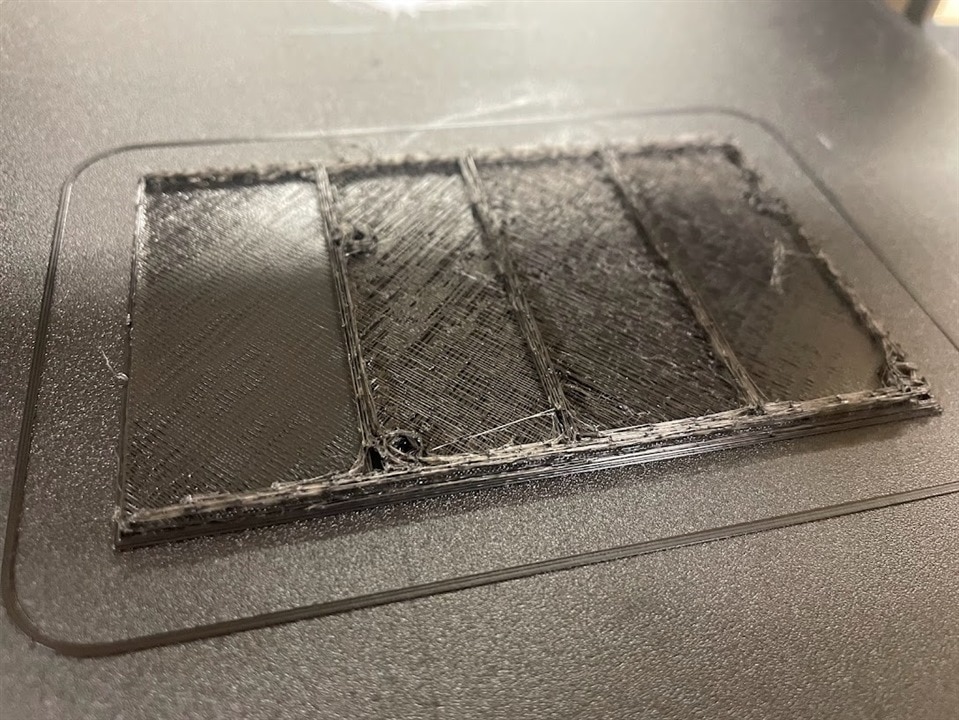

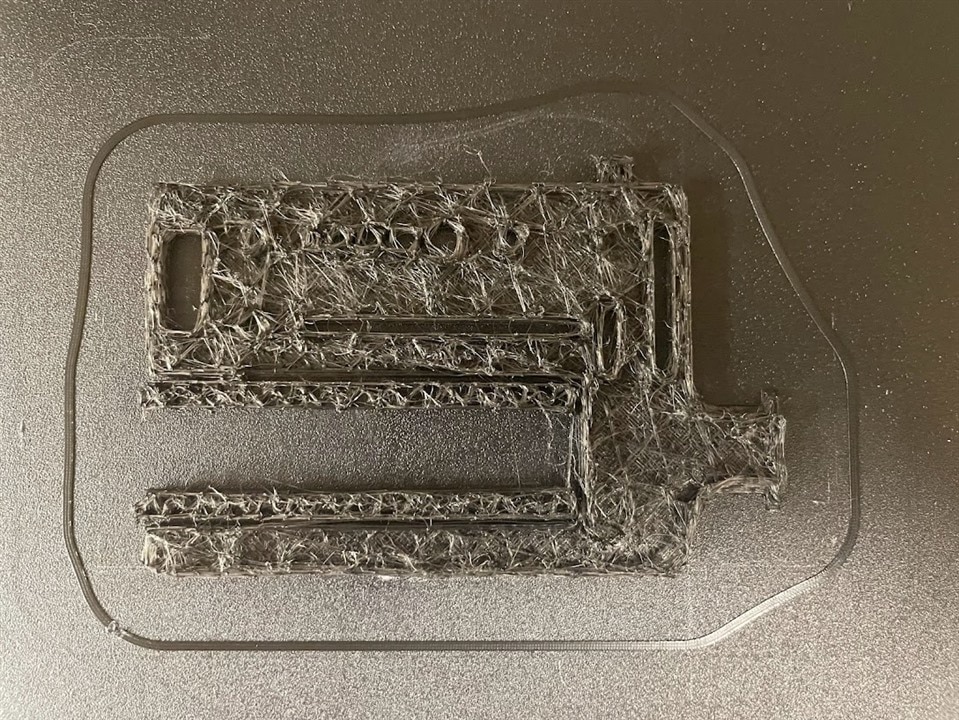

The last thing I printed was a case, in PLA, for a transistor tester, one of those cheapee ones that work well. The outside of the case printed fine but the screw holders on the inside were a loose nest of filament that had no cohesion. They would just snap off with the touch of the finger. It would never hold screws. So I tried printing the lower half again. This time the bottom layer did not even go down well. Tried again. This time even worse!

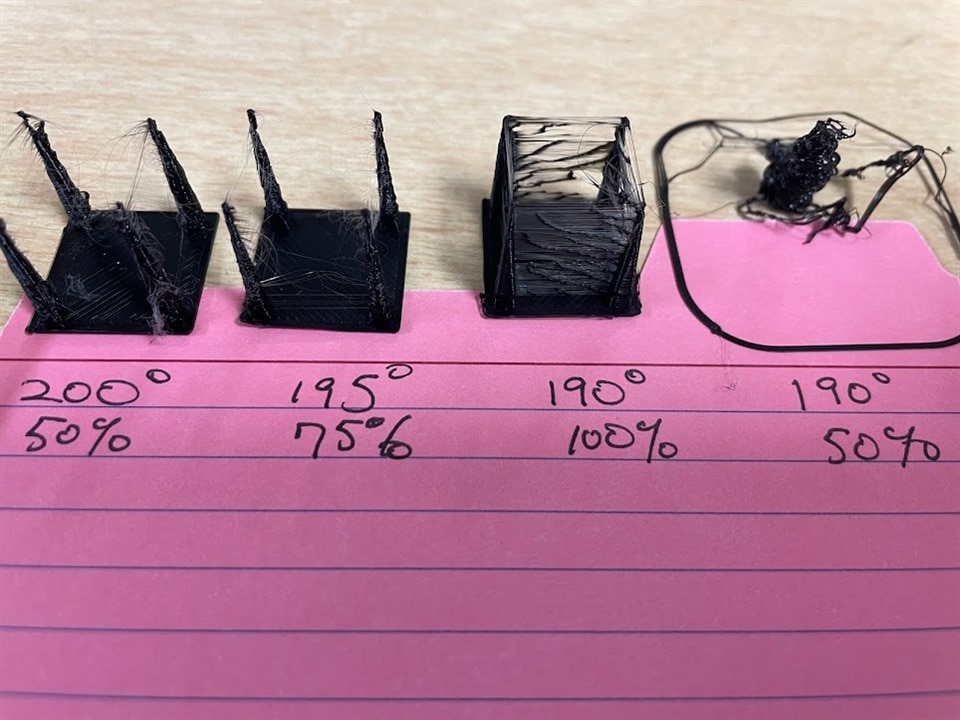

Ok after consulting different forums, I was first told my extrusion temp was too low - stock Cura setting is 200. I bumped it 210. Nope. Then I was told to clean the extruder nozzle, which I did. Nope. Then I was told to check the z step. So I went through the process of calculating that and adjusted it. No difference.

At this point I started over. I

- leveled bed again (still didn't work)

- cleaned nozzle again (still didn't work)

- tried different extraction settings (on/off, speed etc) (still didn't work)

Today I went back to the default settings and tried printing it one more time (and then a second and third attempt..). Now the skirt won't even lay down properly. Any guidance for what is going on or where to start (again) with this? I keep the PLA and PETG in the foil pouches they came in with dessicant but I don't have a dryer or use the oven before printing.

Here is a link to the photo album of first good prints and then the degradation over time to the last picture which is from today of the bottom of the tester case I am trying to print again.

https://photos.app.goo.gl/PmBKJQojMPebxnpJ8

Thanks

Robert Opalko