Hello everyone,

I have been working on a project that all of the 3D printer enthusiasts would definitely like! We often face trouble forgetting to place the order once our filament is coming to an end. Well, no more!

The Concept

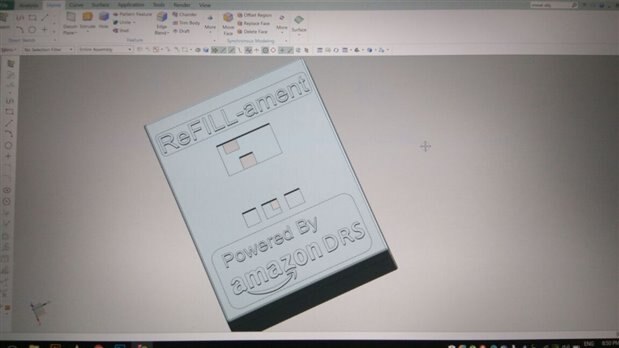

ReFILL-ament is special Amazon DRS enabled device, that helps you calculate the usage of the filament for 3D printers, and re-orders itself when the filament is about to run out.

All the 3D printers print the object using the filament, melting it and shaping it up as per the required specification. The filament is like the ink refill of our pen. Without refill ink, we cannot write and without the filament, we cannot print 3D objects.

So what happens, when we have thought of an idea! Prepared a 3D model for the same after many iterations, and we are eager to print it visualize our imagination. Until you realize that you don't have enough filament to print the object! That actually kills the imagination and the enthusiasm in us. So to avoid that embarrassing moment, ReFILL-ament takes care of your usage, and orders on your behalf, so that you never run out of filament and the new one arrives before the old runs out!

The basic idea is to create a completely standalone device that orders the filament on the preferences chosen earlier while configuring. The device would be packed in 3D printed enclosure so that it is easy to maintain it. Being USB-powered, there will be less of hassles!

ReFILL-ament reads the RFID card attached to the filament to identify which filament is currently under use. It also as an IR Array on the reverse. So, the design on the RFID card is made such a way that it cuts 3 IR in sequence. A combination of RFID information and a complete IR sequence helps the device to count the number of turns, and eventually estimate the remaining filament on the reel.

ReFILL-ament Setup with 3D-Printer

Following video shows the setup of ReFILL-ament with your 3D-Printer and register your ReFILL-ament device with Amazon DRS by the product registration web page.

ReFILL-ament in Action

Following video shows how ReFILL-ament tracks usage of maximum three filament reel and place order on Amazon on your behalf when the quantity of any of three filaments is less than 30% using filament reel preference (ABS/PLA and Color) for each filament reel selected during ReFILL-ament Product registration process with Amazon DRS.

(NOTE: In this video 1 unwound is considered 1% usage just for demo purpose, in real use based on length/number of wounds of filament this percentage use can be set to actual)

What is unique in ReFILL-ament?

- Stand Alone device works with any 3D-Printer without even touch 3D-Printer.

- Track usage of 3 filament spool and can be used to track more spools with little modification in the code.

- USB powered device with Support of most of Amazon DRS API by ESP8266.

- A meaningful status display on OLED Display.

- if Internet connectivity not available then also tracks filament usage.

- The Same project can be used for track any kind of spool usage and reorder the same. So it's not only applicable to 3D-Printer.

- Low cost and easy Hardware design with easily available components makes this project really DIY so someone can easily replicate (Low-cost ESP8266 SoC, Low-cost sensors)

- All current information (i.e. Filament UsageTokens, AP Credential, Slot Status) stored in EEPROM of ESP8266 every time it changes. So on every power cycleRefillament retains the latest information.

- All Amazon DRS APIs implemented for ESP8266 SoC, Just Authorization Code generation done at Product Registration Webpage. So it will be easy for makers to implement the similar project without much knowledge of scripting...

- Hardware Schematic, ESP8266 Firmware, and Product Registration web page source code all released in open source domain under CC-BY-SA license. So anyone can use this work or contribute.

- Main philosophy used in this project is "Keep it As Simple As Possible" and "Put First Thing First" at the same time also considered end user aesthetics and ergonomics.

For more documentation visit here: https://www.hackster.io/abhijit-nathwani/refill-ament-for-3d-printers-261881

I would love to hear views from the community on the same.

Regards,

Abhijit Nathwani

The Basic Idea

The Basic Idea