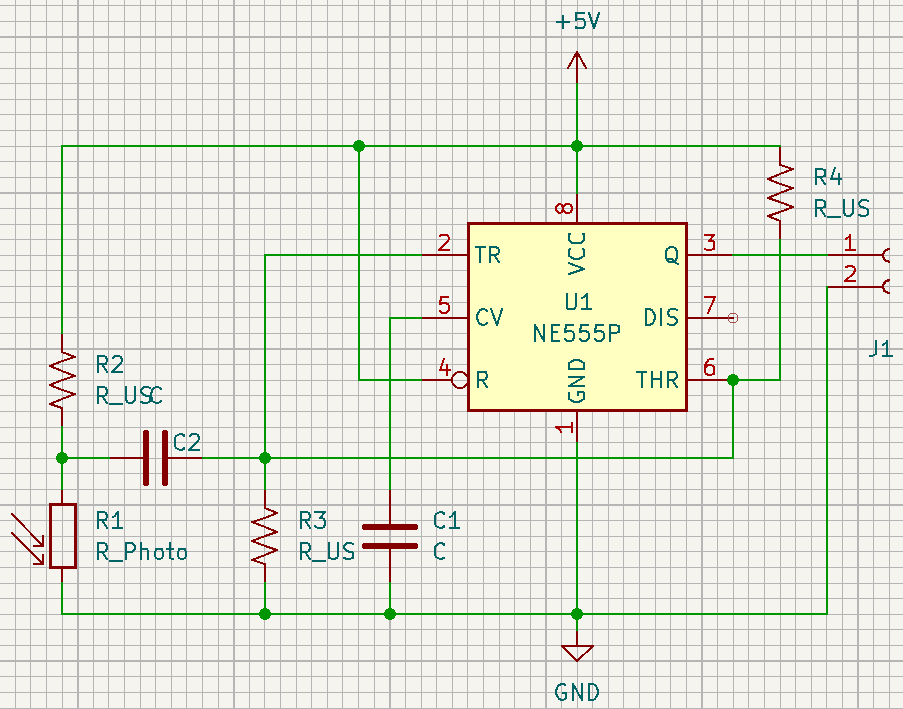

Can I get members insight into using a 555 timer as a schmidt-trigger design that I pulled from the Internet?

I found this schmidt-trigger design using a 555 timer. I would like to use it to condition the output of a photo-resistor. The 555 timer output will feed the input to a Arduino Mega. I'm in the process of bench testing the setup to finalize component values. While testing I figured I would throw it out to some more enlightened minds than mine for feedback.

I'm using the 555 only because I have a stock of them. I don't have any readily available smidth-trigger IC's so I figured I would go with what I have and build from scratch. Building from scratch especially using Internet designs comes with risk. I was hoping to mitigate the risk by getting community feedback.

If inquiring minds suggest you don't want to do this, that is a good thing.