Good day to all.

Long time lurker and first posting; I truly appreciate your patience.

I have been working on constructing a home cockpit representing a Boeing 727-200 using OEM parts/instruments/indicators/gauges I’ve obtained over the years.

Currently, I’m hard-at-work on interfacing these pieces with X-Plane 11. I have many, many questions and as a relative newcomer to the world of electronics (which is like learning a new foreign language to me most times) I would appreciate some assistance.

I’m working on a Flight Director Indicator (FDI) and a Horizontal Situation Indicator (HSI) which both provide vertical and horizontal guidance to the pilots. Luckily, I have the pin out assignments and operation manual for the FDI and am having fun hooking-up wires and seeing the dials slowly turn. The pitch and roll functions are controlled by synchros and motor-generators via 26VAC/400Hz. The warning flags are powered by 28VDC.

On the topic of op amps—-

There is a ‘needle’ indicator for the glide slope (which provides a ‘path’ to follow when approaching the runway to land). This needle indicator is biased from view when the glide slope receiver does not detect a glide slope indication. When approaching the runway and intercepting the glide slope at a specific altitude, the needle will move slowly move down from its hidden view. When the needle reaches its centered position, you are on the glide slope and continuously descend to the runway, keeping this needle centered.

This needle requires very little power, both positive and negative. Full deflection in either direction (above glide path and below glide path) is minimal; this indicator is extremely sensitive as it is designed to guide the pilot to the runway in very low visibility conditions—precision is paramount.

Given this, an op amp (based upon the reading and research I’ve done) seems the logical choice for operation. I have been successful in getting the needle to move from full up to full down by switching the leads for positive and negative power, using extremely low amps from my 28VDC bench power supply.

From the unit’s manual:

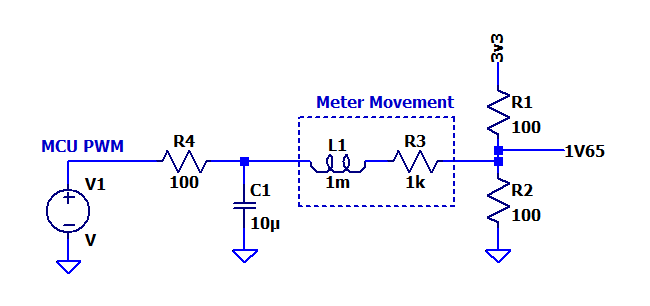

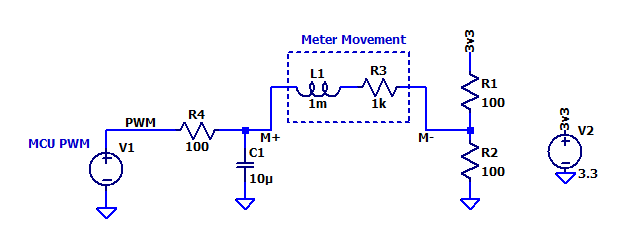

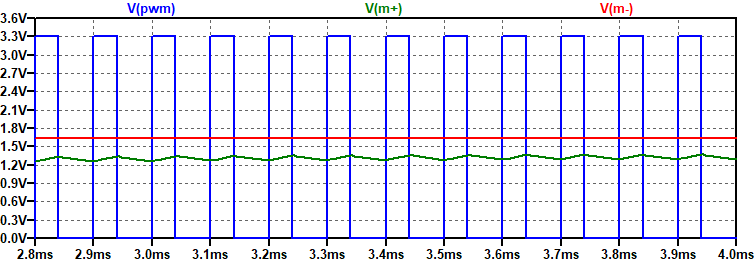

”Meter mechanism sensitivity is 150 +/-20 ua in each direction and is biased from view with 1.5 ma maximum and is in view with 500 ua applied. Meter resistance is 1000 +/- 30 ohms.”

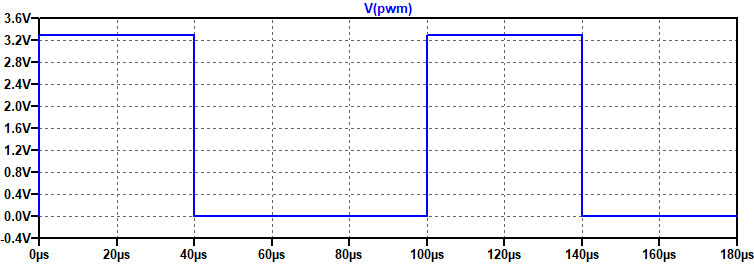

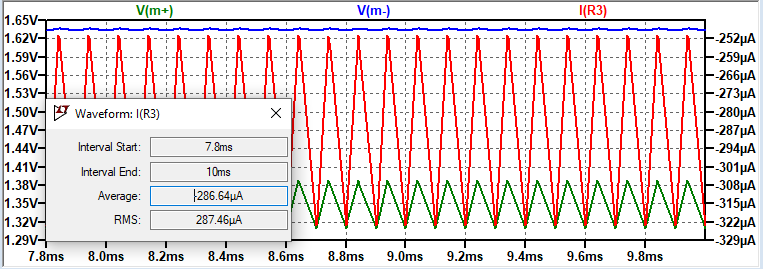

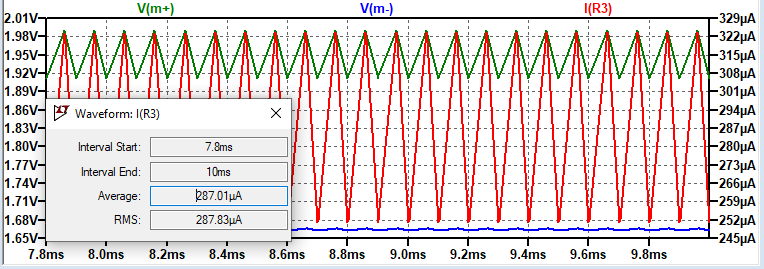

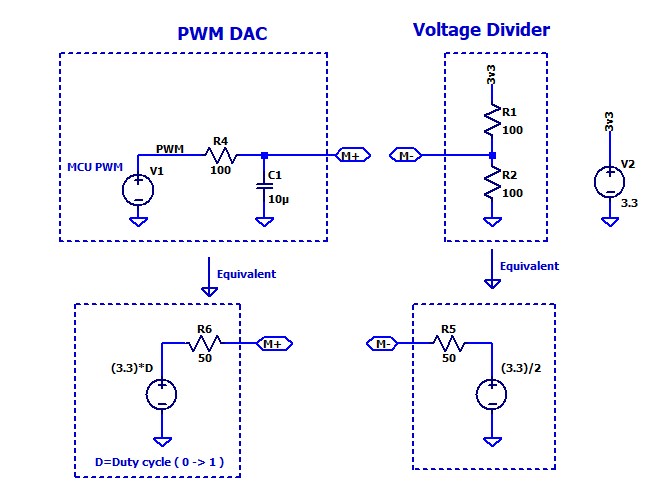

I will be using a Teensy board which provides power of 3.3VDC with PWM. I’m not concerned with the coding/sketch to drive this instrument as that has already been established.

How would I apply Ohm’s Law to drive this needle using various values of resistors/diodes or other components, given the tiny amount of amperage (positive and negative) required? And then the question of which type of op amp to purchase? I have done some research on the topic of op amps and am still a little unclear to their full capabilities and/or limitations. I had seen an op amp board available from SparkFun which looked promising but I wanted to first ask as I see many, many friendly, patient and helpful suggestions and advice here.

I certainly appreciate your input.

Jay

Las Vegas, NV