According to my Google search, NFC uses ASK modulation to transmit data:

https://www.rfwireless-world.com/Tutorials/NFC-Near-Field-Communication-tutorial.html

https://www.rfwireless-world.com/Tutorials/NFC-Modulation-and-NFC-Coding.html

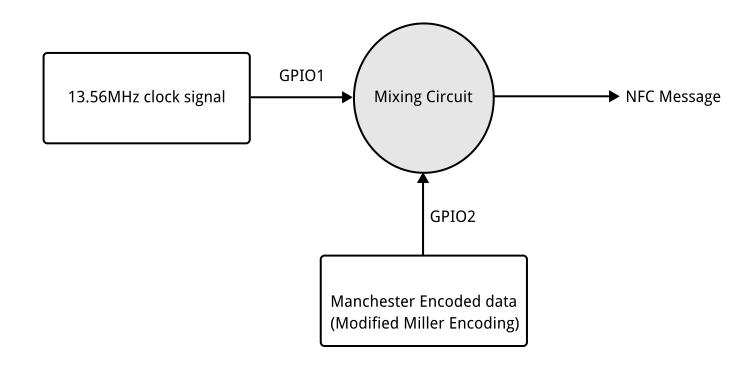

Which I have interpreted as the following where the "Mixing Circuit" includes the NFC tuned antenna and two picoFarad capacitors... but what else is needed.

As a non electronics engineer I am trying to work out a minimum circuit required.

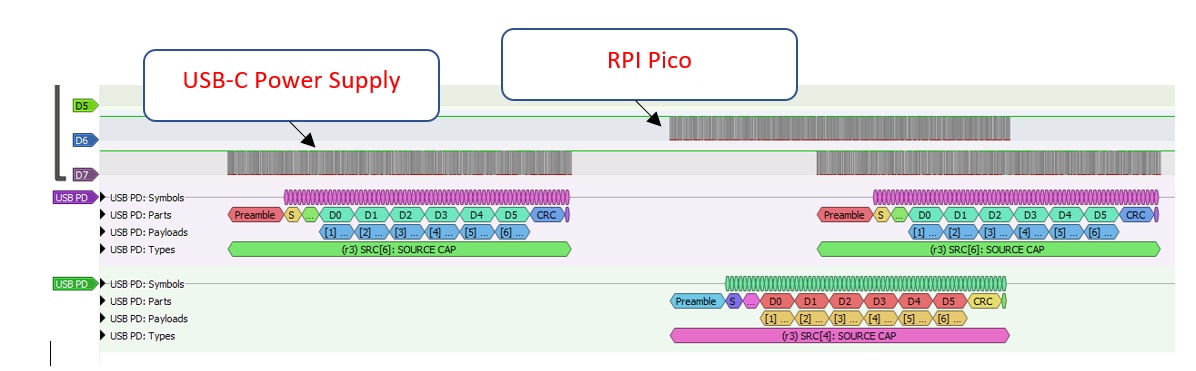

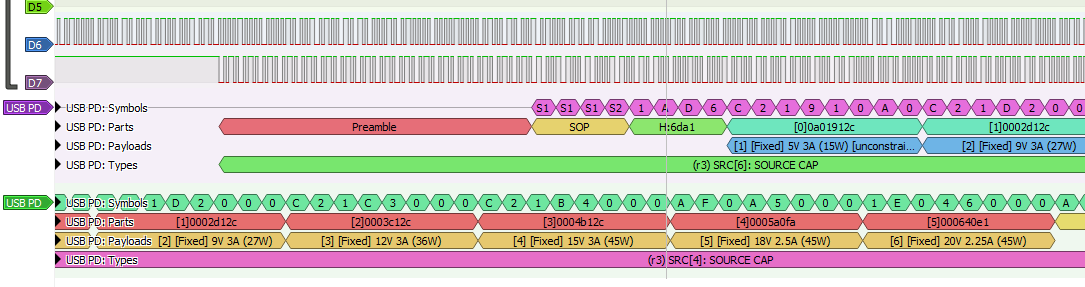

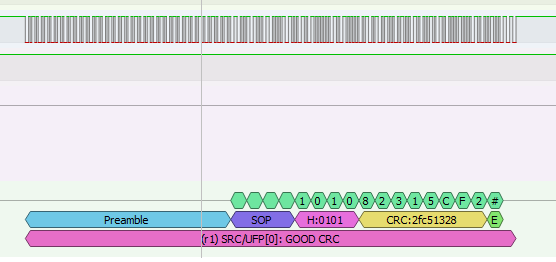

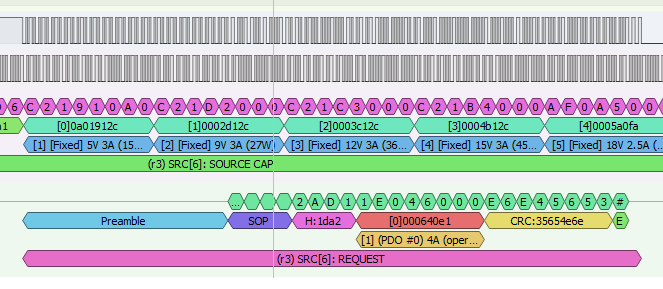

Then my lofty intentions is to use a Raspberry Pi Pico to generate my clock signal using PIO and as there is also a Manchester Encoding PIO example, I will attempt to use that too.

So could this work, I wonder?