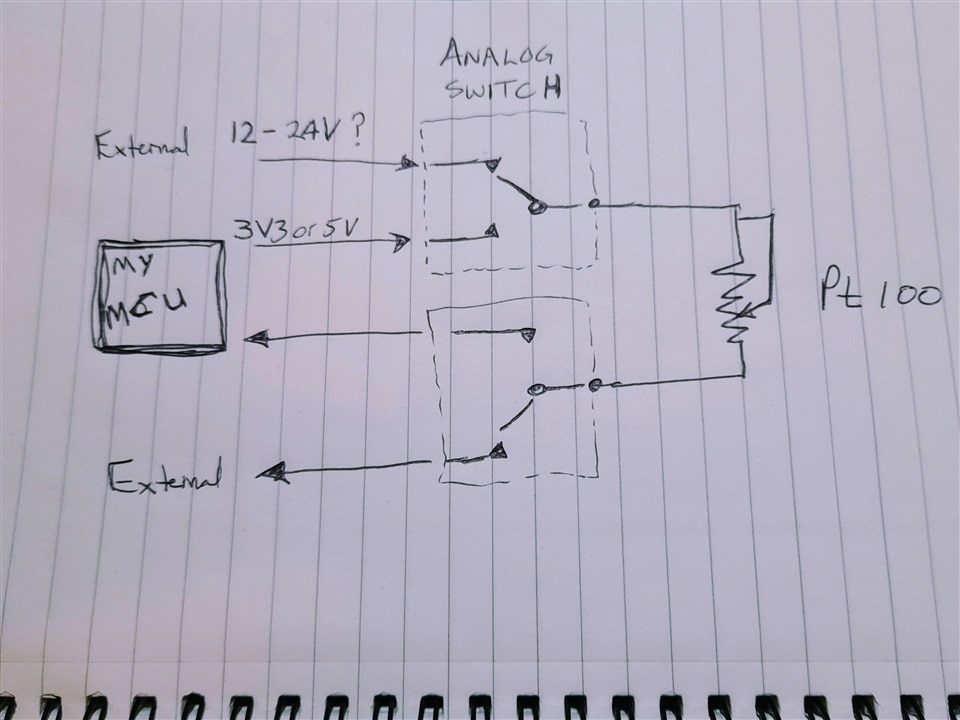

I wish to create this circuit (not a fully complete design), where I am hijacking a Pt100 sensor for my own readings while still allowing an existing system to read the values correctly. I'm thinking that if I switch fast enough, with the help of smoothing capacitors, I could just about get away with it as there will be a fair bit of sampling and averaging to get a temperature value.

To do this, I decided to use an analog switch as these typically have low on resistance values. What I cannot figure out is whether I need a device like a Vishay DG419LEDY-T1-GE4 which has a signal range of -15V to 15V or I could use a SPDT analog switch with a lower voltage. I think I am correct in thinking that the max voltage of Vin is the max voltage allowed through the COM-NC pin etc.

I just wanted confirmation.

Of course, if there is an easier way to do this, I love to hear your views as I have a habit of over complication.

Thanks

Colin