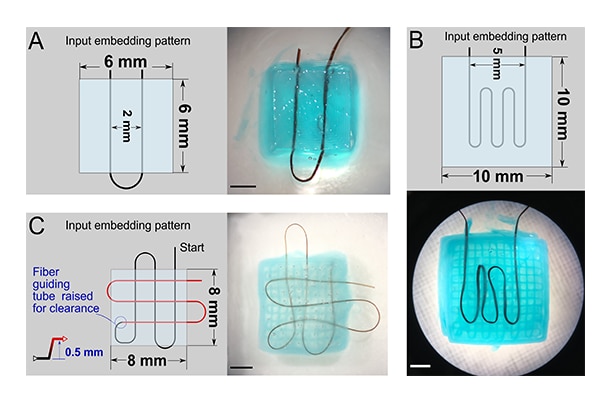

The diagram shows how the fiber extruder embeds into the hydrogel. (Image Credit: Biohybrid and Organic Robotics Group, Carnegie Mellon University

Recent hydrogel 3D printing advancements led to a hydrogel structure with complex 3D geometry, making them suitable for tissue engineering, soft robotics, and drug delivery applications. Carnegie Mellon University researchers developed an inexpensive, open-source fiber extruder designed to benefit future research with hydrogels and soft robotics.

Hydrogels start as monomers in a liquid form. The sticky liquid, typically composed of synthetic or natural materials from polyester to sodium alginate, serves as ink in 3D printers. Putting hydrogels in the appropriate environment allows the monomers to produce polymers that shape the hydrogel and allow it to hold in water. However, hydrogels are tender, making them unsuitable for robotic applications. So the team developed a continuous fiber extruder, a device that strengthens the hydrogels, keeping them from breaking apart or losing shape when loaded.

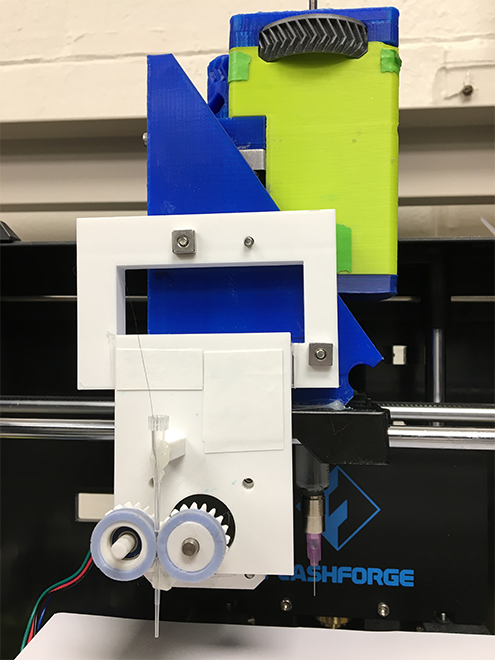

3D printers are required for the fiber extruder to reinforce toe hydrogel. (Image Credit: Biohybrid and Organic Robotics Group)

Implanting fibers into hydrogels as they're printed strengthens the mechanical properties, resulting in a more durable structure. This new open-source, commercially available development benefits future studies with hydrogels and robotics. It only costs $53 to develop and can be used with various home-based 3D printers. It also underwent successful testing with synthetic and natural fibers, like silk and collagen.

"This paper describes the entire process of how we built the fiber print hub so that other people can just reference our work and then build their own without additional instruction," said Wenhuan Sun, a Ph.D. student in mechanical engineering.

A highly-maintained hydrogel structure makes them applicable for many different purposes. For example, it can be used for drug delivery and tissue engineering due to its flexibility and softness. Even then, the physical sturdiness paves the way for tasks in soft robotics. "Since the continuous fiber extruders work well with natural materials like collagen and alginate, reinforced hydrogels are poised to become an adaptable material for soft robots, and they are an environmentally friendly one, too."

"We're really interested in how we can use biodegradable materials in robots," says Webster-Wood, an assistant professor of mechanical engineering who founded the Biohybrid and Organic Robotics Group. "These plant-based hydrogels are a really interesting direction because we can basically farm the materials for the robots and make them renewable."

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell

-

ysonic

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

ysonic

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children