A better environment contributes to improved health and productivity. Increasing environmental awareness has spurred the development of accurate and affordable monitoring solutions. Carbon dioxide (CO2) sensors can sense rising CO2 levels allowing real-time CO2 tracking for controlled ventilation systems and enabling users to precisely measure and regulate indoor air quality. There exists a proven correlation between CO2 concentration and aerosols, a notable transmission route of viruses. Thus, reliable measurement of indoor CO2 levels using CO2 sensor technology would effectively manage virus transmission risks. This blog explores Infineon-specific XENSIV PAS CO2 senor and its use in IoT networks.

XENSIV PAS CO2 environmental sensor is a disruptive CO2 sensor based on the photoacoustic effect. It works on the photoacoustic spectroscopy principle. The principle states when pulses of light from an infrared source pass through an optical filter tuned to the CO2 absorption wavelength (λ= 4.2 µm), the CO2 molecules inside the measurement chamber absorb the filtered light, causing the molecules to shake and generate a pressure wave with each pulse. This phenomenon is called the photoacoustic effect.

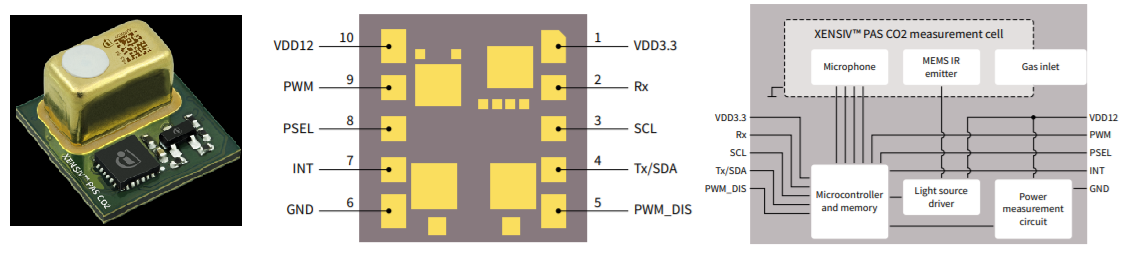

XENSIV PAS CO2 integrates the photoacoustic (PAS) transducer, including an acoustic detector (MEMS microphone), infrared source, an optical filter; a microcontroller for signal processing and algorithms; and a MOSFET chip to drive the infrared source on a single PCB. The highly sensitive acoustic detector senses the pressure change generated by CO2 molecules within the sensor cavity, and the microcontroller converts the output into a CO2 concentration reading, encoding to an I²C, UART, or PWM serial interface. The acoustic detector optimizes for low-frequency operation, and the absorption chamber is acoustically isolated from external noise to achieve the most accurate ppm reading. The integrated microcontroller runs ppm calculations and advanced compensation and configuration algorithms. Figure 1 shows the pinouts and blocks diagram of this sensor.

Figure 1: XENSIV PAS CO2 environmental sensor

The exceptional sensitivity of this acoustic detector coupled with the integrated PCB design reduces space requirements by more than 75 percent compared to commercially available CO2 sensors. Therefore, the XENSIV PAS CO2 sensor outperforms state-of-the-art NDIR sensors in size and cost without compromising performance.

The sensor comes in a 14 x 13.8 x 7.5mm, exceptionally miniaturized module that is many times lighter and smaller than its NDIR counterparts. It delivers high data quality with superior accuracy (±30 ppm ±3% of reading).

The available configuration options make the sensor one of the most versatile plug-and-play CO2 sensors on the market. These options include dedicated ABOC (Automatic Baseline Offset Calibration), pressure compensation, signal alarm, sample rate, and early measurement notification, mainly suitable for power consumption management.

This ease of integration makes XENSIV PAS CO2 the right fit for various applications in building automation, smart home, and air quality monitoring. In HVAC, the sensor ensures optimal indoor air quality levels. Furthermore, by facilitating DCV (demand-controlled ventilation), CO2 sensing leads to an increase in the energy efficiency of these systems and significant savings on energy bills. It is ideal for Smart home appliances and IoT devices such as air purifiers, thermostats, Smart lighting systems, air quality monitors, and Smart speakers.

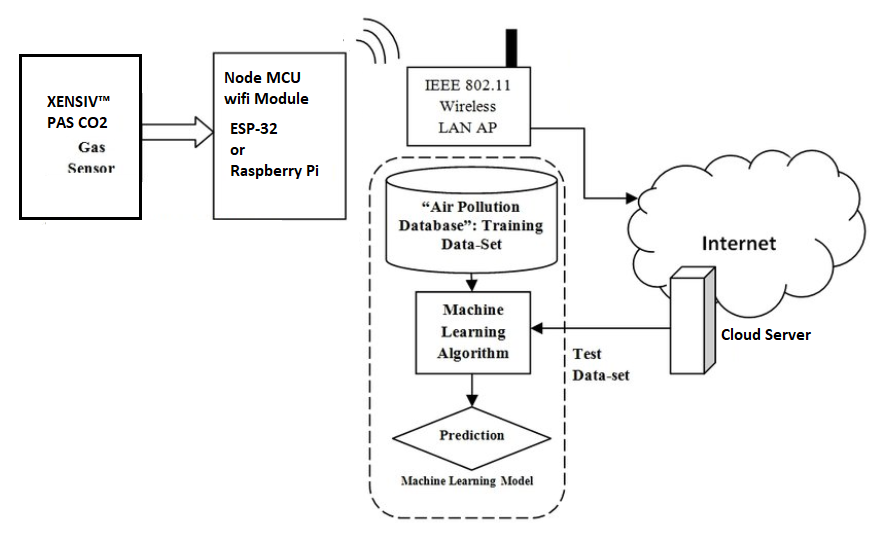

Figure 2 shows the use of XENSIV PAS CO2 sensor in an IoT-based Air Pollution Monitoring System, where its digital output interfaces with any microcontroller or microprocessor equipped with Wi-Fi-like ESP-32 or Raspberry Pi. The sensor data received by Node MCU goes to the cloud server through a WLAN adapter. This work includes a machine learning and forecasting model, a predictive modeling subset, to predict the CO2 level.

Figure 2: XENSIV PAS CO2 Sensor used in IoT based Air Pollution Monitoring System

The predictive and forecasting model uses Machine Learning (ML), which mainly deals with computational methods that enhance the task of automating the assurance of learning from the encounter. ML is a process where a machine learns from a complex data set and solves critical problems. The pollution (CO2 level) forecasting model, like regular weather forecasting, is used to take preventive measures. The process of building the prediction models involves three steps. The first step is data pre-processing, where data undergo sanitation, missing values filled, outliers removed, and data arranged to fit the ML algorithms. Then comes Feature Engineering concerning the attributes that increase prediction accuracy, such as day, month, and time of the day. The last step is to build a Forecasting Model. The model predicts the future, i.e., on the unseen data based on the historical data. The training data includes known target variables and their selected features used in all algorithms. The developed models are cross-validated and evaluated during the test stage.

Top Comments