This is a thread to discuss ideas for controlling low-cost hardware (machines), for the purposes of cutting or engraving for example. It was created due to the interest in ralphjy project to assemble such a device.

There are several ways to do this, typically the 'brains' are a normal desktop or laptop PC, or a single board computer (SBC), and then there is some interface board, that then ultimately connects via high-power drivers, to the motors. There are some other bits of functionality too, like feedback (e.g. limit switches) for detecting end stops.

In terms of motors, in industry servomotors will be used, but for home use stepper motors are a lot more popular due to lower cost. For controlling the tool, a 'spindle motor' may be a brushless motor, or alternatively a brushed permanent magnet DC motor (i.e. BLDC or PMDC motor respectively).

The PC connection to the interface board can typically be a parallel interface, or USB. When using a SBC then its on-board general-purpose input/output (GPIO) can be used.

The BeagleBone Black (BBB) is worth considering I think, since it has been the first popular Linux product to be integrated into machines, providing functionality for 3D printers and small CNC machines. Commercial manufacturing products have been launched with the BeagleBone inside, such as the PocketCNC. There are also third party add-on boards that act as interface boards (and some that integrate motor drivers too). The BBB is old now, but there is a BeagleBone-AI that could in future be used as an upgrade.

Partly the reason the BBB has been useful is because it contains some programmable real-time units (PRU) internally, and they can override some GPIO pins, for direct control without needing to go through the Linux system. So, the Linux system can push code to execute on the PRU, and the PRU will control the pins. This means high speeds, and no unexpected delays or jitter, since the PRUs are simpler devices that do not run an operating system that could have a task preempted.

To control the interface cards, PCs have a wider choice of software, and popular choices are Mach 3 and LinuxCNC. For the BBB, the software all the boards seem to use is called Machinekit, which is a fork of LinuxCNC.

Using it for BBB is not documented well unfortunately. When I first started looking a while back, it was hard to tell which information works, and which information is old. I wanted to automate a simple XY table I'd bought.

However, there is a fairly recent blog article with useful pointers. It too discusses that information is spread out.

It would be nice to develop hardware (or to at least consider it first), and any software or configurations, documented, that would allow low-cost control of machines, and to bound it a little, to only consider home-grade machines using stepper motors, not servomotors. I think there is value in a new open source design, to collect up the wisdom of the various CNC users here, so we can all have low-cost home robots to make things for us!

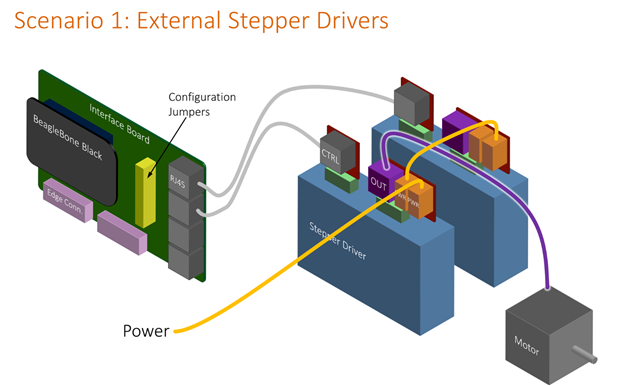

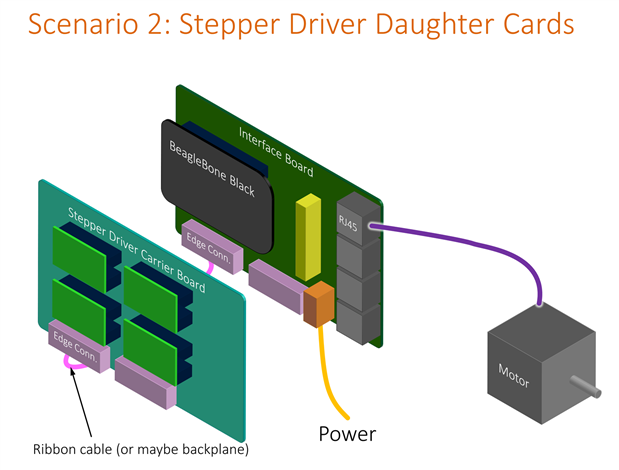

After some initial thinking, these sketches were a couple of ideas: They are based around the thought that the BBB could be a plug-on daughter card on a larger interface board, that uses something like RJ45-style connectors (because it would be nice to use off-the-shelf cables where possible, to reduce wiring effort, otherwise there are a lot of wires to connect).

After some further discussions with balearicdynamics, it was suggested that scenario 1 could be more practical since it can handle more motors (low power and high power). I too like that idea, since it is one less board to make.

Edge connectors or some other connection location could still be left on the board, for those who do want to have a custom board for add-ons (e.g. to control a 3D printer instead, where they may need outputs for say a heater).

More input to any of this, including the practicality of it all, and board design (physical as well as functionality), and connector choices, is welcome. Meanwhile, I've been looking at the existing boards that are supported by Machinekit, to see what pins they use of the BBB, and why. I'll have to install Machinekit to better understand it. So far, I've looked at boards (or Machinekit configs) called CRAMPS, Replicape, and BeBoPr-Bridge and all use different pin mappings. I need to figure out which of these configs are using the PRU, and if so, which pins to allocate for that. I like the CRAMPS pin mapping so far, because it avoids eMMC and HDMI clashes (the BBB has these brought out to its connectors, and some interface boards tend to use these, which rules out using eMMC or HDMI as a result).

The pin mappings are in text files, but not easy to compare, so I've put them in a spreadsheet, I'll attach that as soon as it is complete.

The pin mapping text files are: CRAMPS.hal, replicape.hal, BeBoPr-Bridge.hal (I'll look at a few more too, and put them in the spreadsheet).

The mappings are numbers like 817, which means header P8 on the BBB, pin number 17.

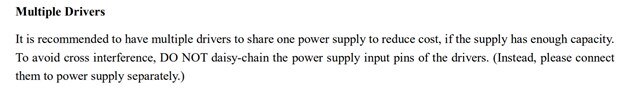

EDIT: I'd hoped to daisy-chain the supplies, but looking at the user docs of a random one, it recommends against this practice:

So, the in/out connectors may not be a good idea, and a single power connector on each motor driver could be preferred.

I'm still looking for a suitable connector, but thinking it may as well be another RJ45-style, since I cannot think of another high power cheap alternative. Ethernet will carry lots of current safely, if wires are paralleled. There is the risk of accidentally plugging it into the wrong socket, but they could be color coded.