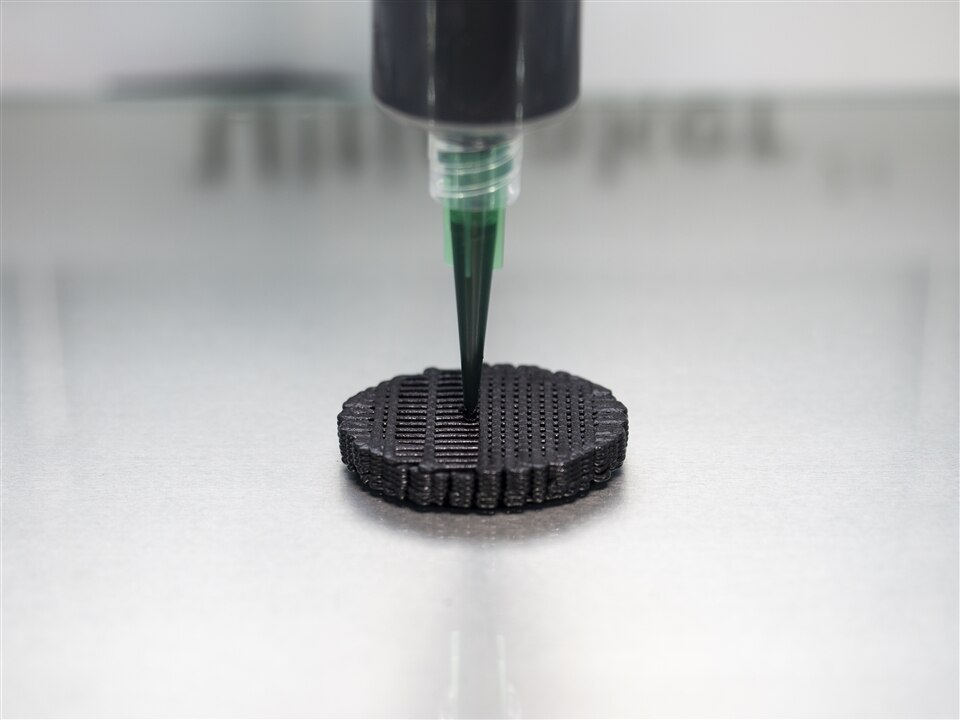

Empa’s 3D-printed biodegradable fungal battery can supply power to temperature sensors for days. (Image Credit: Empa)

Researchers at Empa’s Cellulose and Wood Materials laboratory developed a 3D-printed fungal battery that doesn’t need to be charged. Instead, it feeds on sugars to power temperature sensors for agriculture and environmental research. After supplying power, the fungal battery consumes itself from the inside.

According to the paper, a battery generates a maximum power density of 12.5 μW/cm2 and a maximum current density of 49.2 μA/cm2 (22 kΩ). Also, the fungi battery produces 300-600 mV of electricity for several days, “delivering 3–20 μA for external loads between 10 and 100 kΩ.” Connecting four batteries in parallel provides a small sensor with power for 65 hours.

The fungi are naturally integrated into the battery at the start rather than added at a later stage. All the battery components are created via 3D printing. Researchers can then structure the electrodes to make it easier for microorganisms to access the nutrients. This is achieved by mixing the fungal cells with the printing ink.

The team says the cell is a microbial fuel cell (MFC) and not a battery. MFCs work by turning nutrients into energy, part of which is harvested into electricity. "For the first time, we have combined two types of fungi to create a functioning fuel cell," says Empa researcher Carolina Reyes. These two fungi metabolisms work in tandem with each other. The anode has fungus with a metabolism releasing electrons. Meanwhile, the cathode contains a white rot fungus, producing a special enzyme to harvest and carry the electrons out of the cell.

While the anode chamber contains 2% ME (nutrient source), the cathode chamber has a 4% ME-filtered supernatant with laccase, copper, and mediator. Electrons are generated via the yeast oxidizing the sugars in the anode. Afterward, a chemical mediator carries the electrons to the anode material and current collector (CC). Then, the CC inks and printed anode’s graphite flakes and carbon particles transfer those electrons to the copper wire. The electrons are distributed to the CC and cathode ink, and another mediator assists with transferring electrons from the CC and printed electrode to the laccase enzyme produced by the wide-rot fungus. Oxygen is then reduced into water by the laccase enzyme, completing the circuit.

The team connected the MFC to an IoT Bluetooth AP4470 demo sensor node, displaying temperature (TMP117 sensor) and voltage via a Bluetooth BL9 receiver. It doesn’t require much power to run the sensor---only 290 mV (minimum), and it draws 12-13 μA from the MFC. Additionally, the team connected the MFC anode and cathode ends to the Bluetooth sensor with an RND Components Experiment development board (RND 255-00004) and circuit wires. An Arduino M5 stack core development kit and Arduino IDE recorded the readings. All the readings for the AP4470 sensor node were obtained using a script via the Arduino M5 stack. Connecting four batteries in parallel to the sensor powered it for 65 hours.

"It is challenging enough to find a material in which the fungi grow well," says Gustav Nyström, Head of the Cellulose and Wood Materials lab. "But the ink also has to be easy to extrude without killing the cells – and of course we want it to be electrically conductive and biodegradable."

The researchers’ experience with 3D printing soft, bio-based materials enabled them to create cellulose-based ink. Fungal cells can utilize the cellulose as a nutrient, helping to decompose the battery once it’s no longer needed. They prefer simple sugars as a nutrient, and these are incorporated within the battery cells. "You can store the fungal batteries in a dried state and activate them on location by simply adding water and nutrients," says Reyes.

The team also faced a few challenges when working with the fungi. For instance, Reyes had to learn electrochemistry techniques and adapt them to 3D-printing inks. Next, the team wants to add more power to the battery and make them last longer. They also plan to try out other fungi types that can distribute electricity. "Fungi are still under-researched and under-utilized, especially in the field of materials science," Reyes and Nyström say.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell