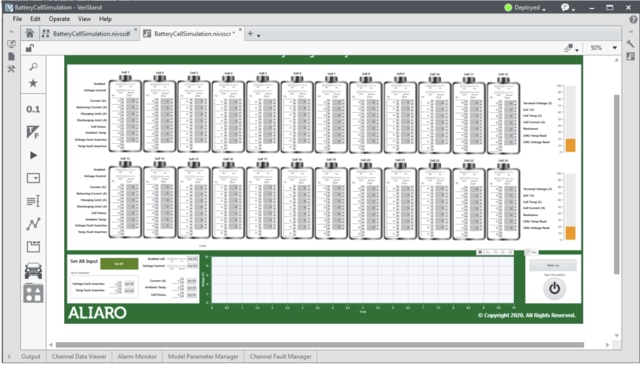

(Image credit: Aliaro)

Swedish firm Aliaro is sparking innovation with its Battery Cell Simulator (BCS), which provides engineers with a new tool for optimizing EV and eVTOL battery systems, without requiring an actual battery. The BCS accurately simulates the behavior of lithium-ion battery cells, as well as entire packs, within a simulated environment, allowing engineers to test and validate designs virtually.

The platform replicates electrochemical reactions and sensor data used by a battery management system (BMS), providing detailed testing of communication protocols, safety logic, fault-detection algorithms, and other key components. The simulator enables users to run performance, degradation, and fault-condition scenarios without requiring physical prototypes, thereby reducing development time and costs.

The BCS also offers manufacturers a fast and repeatable way to adjust energy density, thermal management, and overall efficiency, which translates to extended ranges and safer designs for both EVs and eVTOL aircraft.

On the EV side, the platform can simulate thousands of charging cycles and road conditions, allowing engineers to push battery life and reduce range anxiety. For eVTOLs, it can validate powertrain safety in high-demand flight modes, such as vertical lift or hovering, where battery reliability is critical. As the demand for electric mobility increases, technologies such as Aliaro’s BCS will be key to bringing high-performance battery systems into production faster and with fewer problems.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell