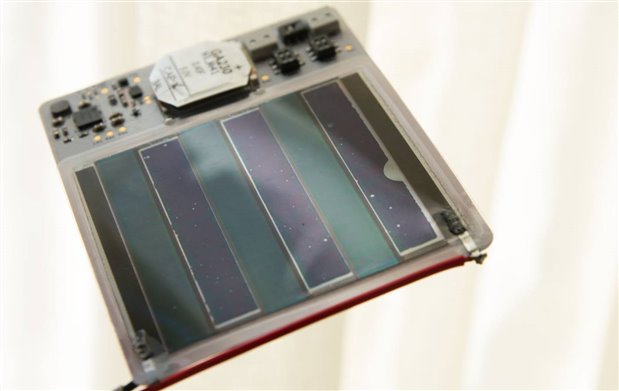

After putting out my initial review on the kit, I somehow felt the review to be a little incomplete, since the star of the show was the organic photovoltaic (OPV) panel and I didn’t really do much to test the panel on its own. The design of the kit doesn’t make it easy to test the panel independently of the harvesting circuit, but that doesn’t mean that it can’t be done.

After some head-scratching, I decided that if I was willing to give it a try even if it meant sacrificing the kit “in the name of science”. After all, that’s what evaluation kits are for, and besides, I think we’ve already learned a lot from it in the first part.

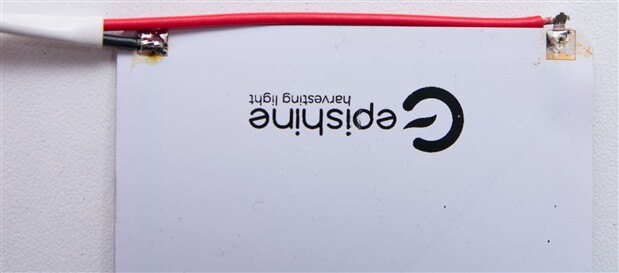

The OPV Module

Data on the OPV module was not provided, so this section will be dedicated to trying to characterise the performance of the OPV module and have a guess at its capabilities. Unfortunately, I don’t have access to a solar simulator, spectrometer, radiometer, reference cell or temperature-controlled environment, so everything will be done on the “cheap” based on what I have to hand. Don’t expect figures that are accurate to even a single decimal place.

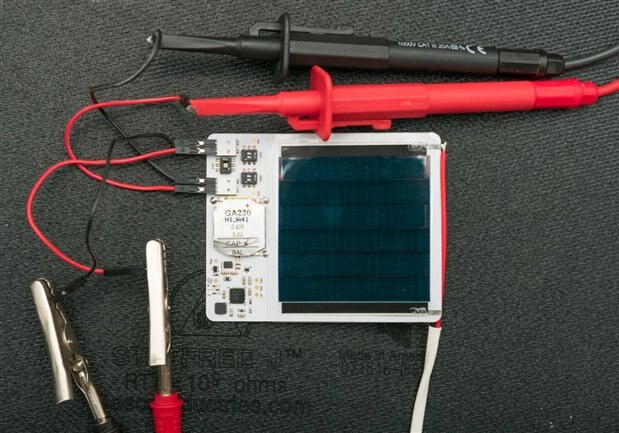

Step one was to gain access to the module itself. Based on some quick tracing, it seems the kit has a common ground, so I isolated the positive tab by carefully heating up the tab with flux and desoldering braid and wicking away enough solder to allow the tab to come free. I took a few breaks in-between, while also using tweezers to grab the tab to try and provide a little heat-sinking so heat did not travel up to the crimp inside the panel. Once it had been freed, the tab was bent back and wires were attached to both positive and negative for measurements.

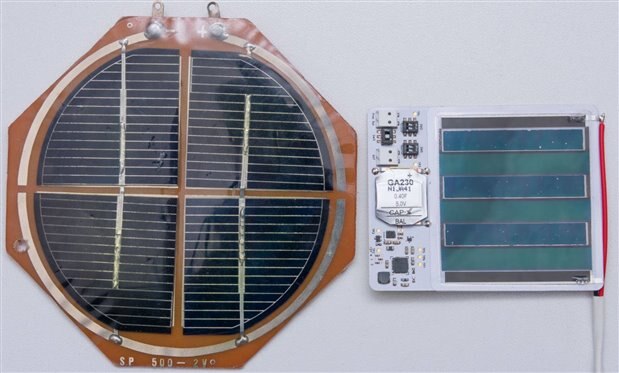

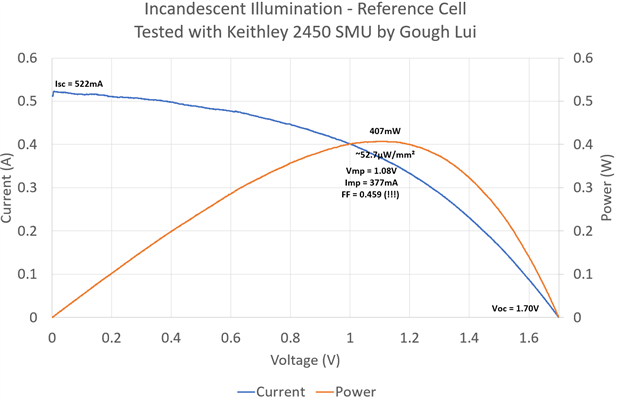

For the purpose of a reference cell, I used an old “hobby cell” that I purchased around 17 years ago from a local electronics shop. This one is rated 2V, 500mA but what this rating means in practice is a bit nebulous. I expect based on the area of the cell (7717mm2) and the ratings that it has approximately 13% energy conversion efficiency under standard AM1.5 conditions (1000W/m2) which fits well with the cells of the time (although perhaps 12% is closer to reality). By comparing the outputs of each cell on an area basis, it may be possible to determine the (approximate) efficiency of the OPV cell (which has an area of 2500mm2).

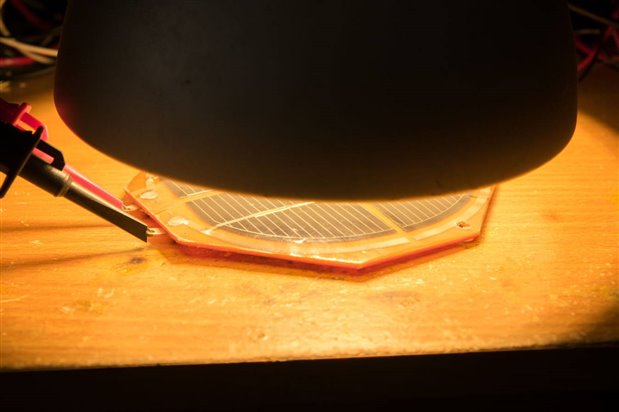

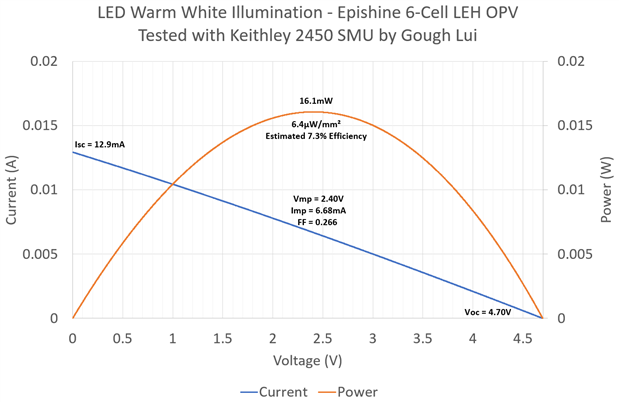

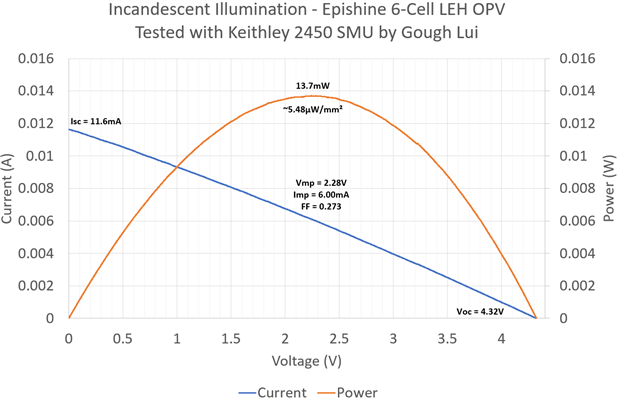

Tests were performed using an IKEA Tertial desk lamp situated above the test panel by a small fixed distance of 20mm. The panel was centred in the field of light and an I-V curve was taken using a Keithley 2450 SMU under SCPI remote control using pyvisa and a script I developed. The light sources were a 11W 1050lm Warm White LED light and a 60W frosted incandescent globe, both of which are expected to have very similar visual brightness but the incandescent would have a continuous black-body-like spectrum more akin to the sun.

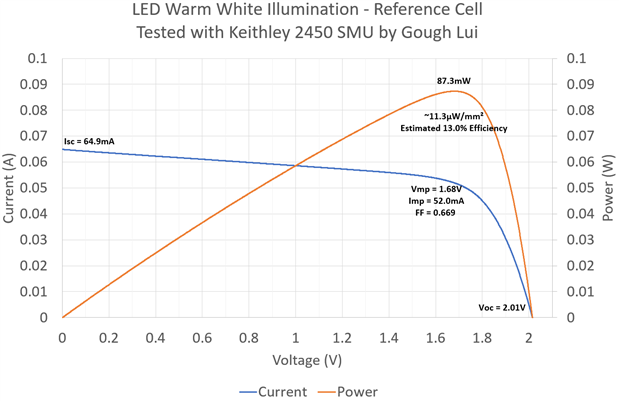

Under the LED source, the reference panel developed 87.3mW of output which is approximate 11.3µW/mm2. The fill factor was a very average 0.669. Perhaps it developed a little less than expected power due to the distribution of light from the LED globe.

Swapping in the OPV panel into the same lighting condition, it developed 16.1mW with an I-V curve that looked like a straight line. This resulted in a poor fill factor of just 0.266, which suggests to me that the OPV technology may have a lot of recombination sites, short minority carrier lifetimes and high series resistances to worry about. The area-normalised power output was 6.4µW/mm2 which suggests the OPV panel achieved around 7.3% efficiency as a ballpark figure (possibly 6-8% more realistically). This is roughly the same ballpark figure for amorphous silicon on glass (i.e. “brown”) panels commonly used in low-cost consumer electronics which is not a bad thing, but its longevity remains to be determined.

Moving to the incandescent source, the reference cell produced much better results, now producing 407mW. Despite looking visually similar, the increased long-wavelength bias in the output spectra may have contributed to more power output although the panel was also heated quite substantially resulting in a significant loss of open circuit voltage and a reduction in fill factor to 0.459. The area normalised output was 52.7µW/mm2.

Under this condition, the OPV panel did not see any improvement – in fact, the produced power decreased slightly to 13.7mW and the area normalised power is now 5.48µW/mm2. The fill factor also remains relatively unchanged at 0.273, suggesting to me that the panel may have “saturated” even under the previous testing condition or is very adversely affected by the heat from the light. Whatever the reason, this result was not something I had expected.

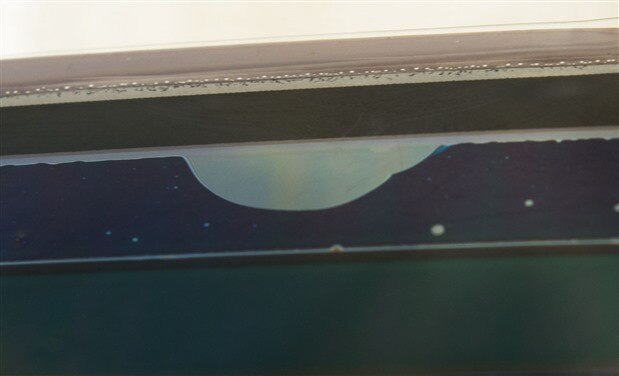

I was, perhaps, too ambitious in this test, as the heat did not leave the panel unscathed. It seems that a bubble has formed, a sign of delamination of the layers of the OPV panel. Despite the plastic appearing transparent, there may be a transparent coating of conductive material and the loss of contact area would increase the series resistance, reducing the panel’s efficiency. A closer look at the panel, even initially, showed some level of bubbles in the panel which suggests delamination could be possible if placed under stress. Once the bubble got somewhat large, poking at it only resulted in it growing. Because of this, I consider this OPV cell to be compromised.

The reference cell too, managed to bubble, as it had a clear plastic encapsulation (partly yellowed) that had probably become partially “liquid” and a bubble formed. This is not too problematic in this case, as the cell is the monocrystalline wafer underneath the encapsulant, although the bubble could affect the absorbance of light in that small area.

Battery Backup

Now that the OPV panel had been disconnected from the circuit, it was probably a good opportunity to try and establish the conversion penalty of drawing down the primary battery backup to power a load. I planned to use the Keithley 2450 SMU to provide an accurate low-current load on the output of the kit and use the Rohde & Schwarz NGM202 to provide the input to the battery terminal, averaging the readings over time using its onboard statistics function to determine the efficiency.

Unfortunately, after piecing together the kit and flipping the jumper to the primary battery back-up position, I wasn’t able to get any output to be developed. I suspect the kit may not want to start-up from “cold” without any input from the PV, or perhaps there maybe something wrong with the kit. I measured the voltage on the rear of the battery input connector and it was correctly reading, the current drawn remained pretty much zero even with the supercapacitor voltage below the output voltage.

Conclusion

This second (and perhaps final) installment covers the Epishine Light Energy Harvesting module itself. By modifying the kit to gain access to the organic photovoltaic cell, it was possible to test it under controlled indoor “high intensity” warm-white LED and incandescent lighting scenarios. The panel, when compared to the monocrystalline reference under the warm-white LED scenario, demonstrated an output which implies an efficiency around 6-8%, similar to amorphous silicon on glass cells. Perhaps being too ambitious, I tested with an incandescent source which seemed to show the OPV cell delivering slightly less power while the monocrystalline reference delivered around four times more. In this test, both cells appeared to suffer some damage as a result of the heat, with the OPV showing a “bubble” which appears to be de-lamination of the cell layers. The fill factor for the OPV panel was quite low, measuring around 0.26-0.27, which suggests that the cells themselves have a number of internal efficiency challenges. Their longevity remains to be seen.

Testing of the battery back-up feature and its efficiency penalties was unfortunately, not possible, as despite configuring the kit based on the information provided, it did not want to draw on the input from the primary battery terminal. The output remained off despite supplying power on the primary battery terminal, which could be due to the harvesting chip not being able to start unless it receives some PV input, but the results are inconclusive.

Top Comments

-

Gough Lui

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

Gough Lui

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children