Solar Harvesting for Remote IoT Networks

Solar power. (Image Credit: Wikimediaimages/pixabay)

Remote IoT nodes still rely on solar power as a source of energy. At the Myriota deployment in June 2025, isolated farms and island resorts had ultra-low-power satellite-connected solar nodes that were powered by off-grid solar monitoring systems. Units usually feature a small photovoltaic panel, charge controller, and supercapacitor or lithium-titanate battery that buffers energy for nighttime use. The input voltage is maintained through power management ICs, which also handle maximum power point tracking (MPPT) for energy capture optimization, particularly under partial shading conditions. This system works autonomously for years without maintenance as it works with sub-µA standby microcontrollers and satellite uplink modules.

Wind and Airflow Harvesting

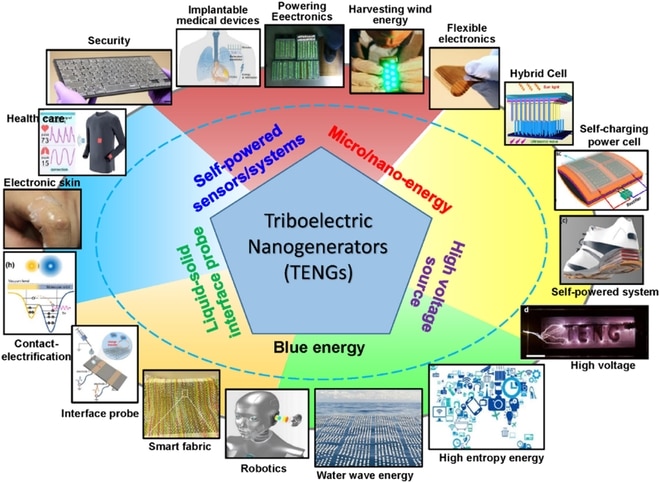

Triboelectric nanogenerators and their applications. (Image Credit: Advanced Devices & Instrumentation)

Small-scale wind energy harvesting devices, such as mini turbines, triboelectric nanogenerators, and electromagnetic transducers, generate power for wireless sensor nodes in civil infrastructure, transmission lines, and remote environmental monitoring. These systems have rectifiers, energy storage (capacitors or microbatteries), and smart PMICs to manage and store intermittent wind-derived energy. In 2025, projects integrated self-powered sensor nodes for monitoring wind speed, vibration, and environmental conditions in areas with impractical battery replacement or wiring.

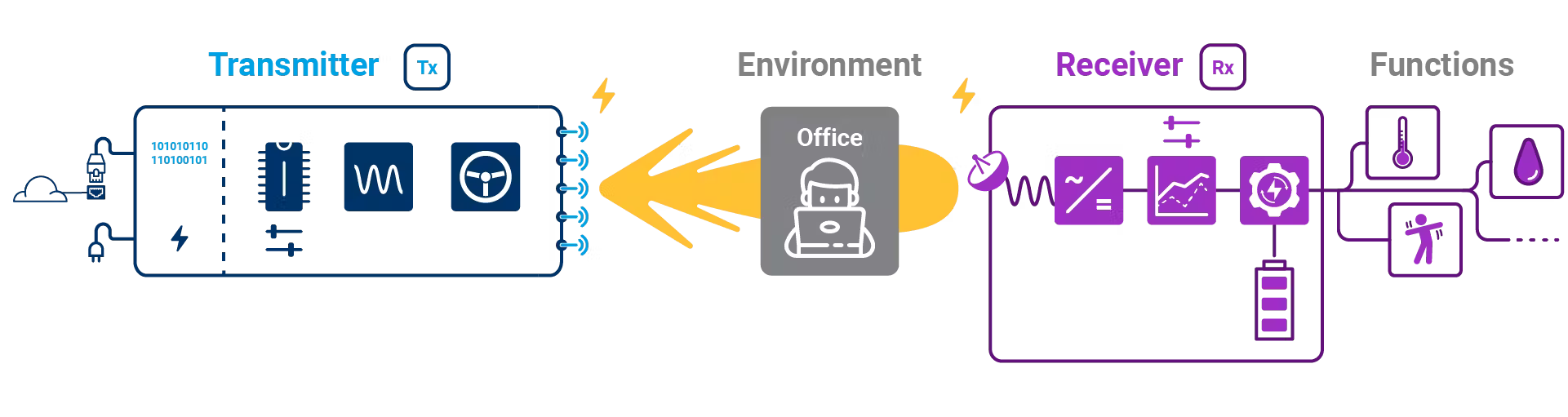

RF Energy Harvesting

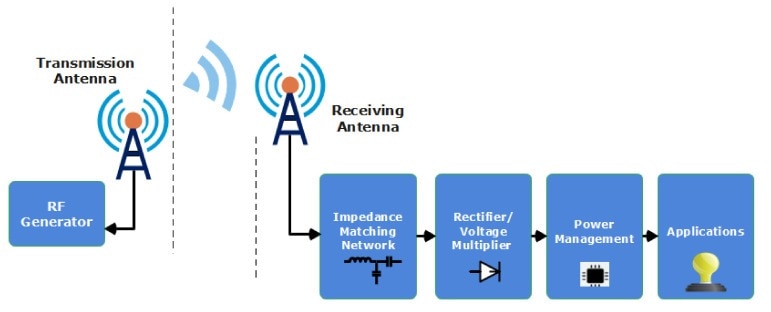

RF energy harvesting block diagram. (Image Credit: National Library of Medicine)

WiFi routers, broadcast antennas, and cellular towers emit electromagnetic waves that are captured and converted into DC power by RF energy harvesting systems. The RF signal is transmitted to a rectenna, which is accompanied by a matching network that maximizes energy transfer efficiency. A DC-DC converter then conditions the rectified output before it's stored in a capacitor or thin-film battery. Powercast integrated this technology into smart home sensors, remote meters, and asset-tracking tags.

Thermal Energy Harvesting

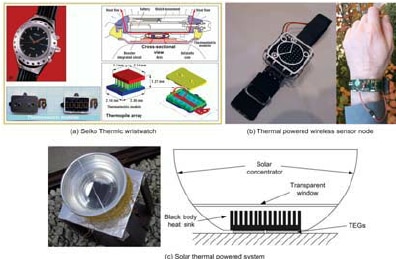

Thermal energy harvesting system examples. (Image Credit: ResearchGate)

Sheetak manufactures thermoelectric generator (TEG) modules and energy harvesters designed to convert waste heat from pipes, exhaust vents, and other industrial sources into electricity for autonomous or wireless sensors. These have a TEG placed between a hot surface (pipe or exhaust vent) and a cold-side heat sink, producing a voltage proportional to the temperature gradient. A boost converter or energy-harvesting PMIC stabilizes the voltage before charging a capacitor or battery cell. Self-powered nodes like these power vibration, flow, or pressure sensors continuously in areas with impractical wiring or battery maintenance.

Vibration and Motion Harvesting

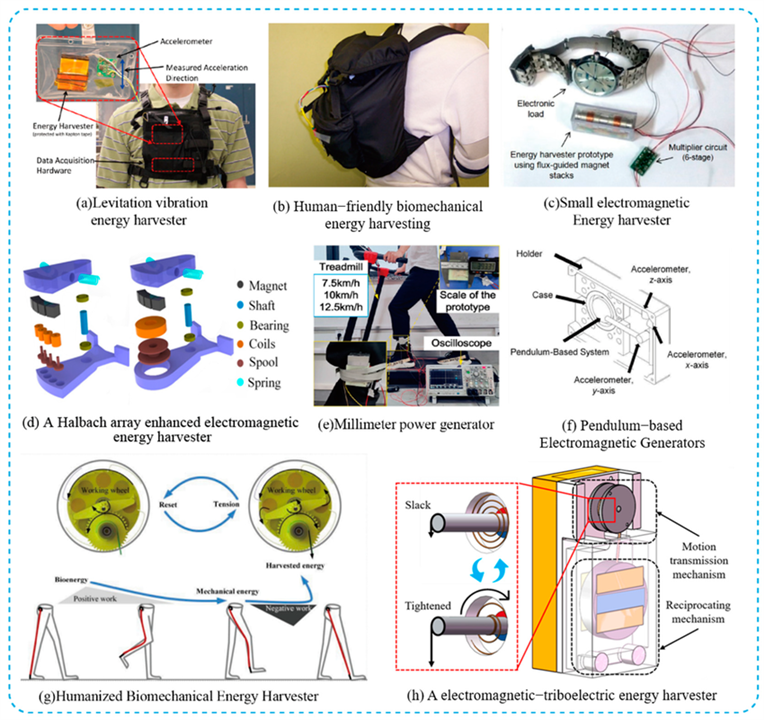

Example of an energy harvesting device based on human motion. (Image Credit: ResearchGate)

Piezoelectric or electromagnetic transducers turn mechanical vibration into electricity. Typically, these systems produce voltage from exposure to motion or strain for infrastructure applications like railways, bridges, or industrial machinery. An interface circuit then rectifies and regulates the harvested energy before it charges a capacitor. In 2025, projects involved integrating LoRaWAN sensor nodes into steel structures, collecting tiny vibrations for year-round monitoring. It features a low-leakage capacitor, bridge rectifier, piezoelectric element, and an energy-harvesting PMIC optimized for sub-milliwatt inputs. The system monitors stress, displacement, and load cycles without relying on wired power.

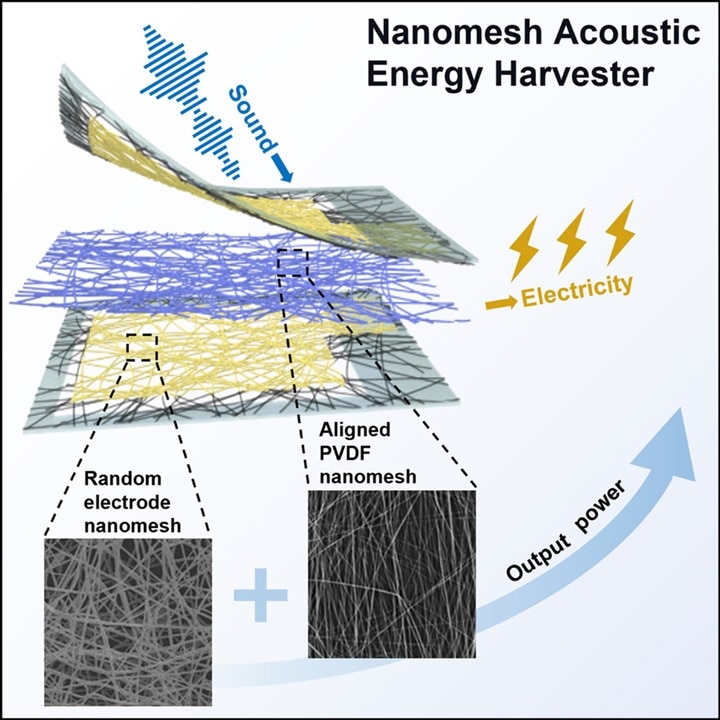

Acoustic and Ultrasonic Harvesting

Acoustic energy harvesting system. (Image Credit: Cell)

There's also acoustic energy harvesting, which involves tapping into sound and ultrasonic waves to generate small, useful energy for distributed sensors. Research recently unveiled flexible, wearable acoustic energy harvesters made of piezoelectric polymers like PVDF and nanocomposites. They typically harvest energy from sound frequencies ranging from 50 to 1000 Hz. Commercial labs have installed acoustic transducers in smart buildings, factories, and airports that generate significant noise. Systems include a MEMS acoustic transducer or piezoelectric diaphragm to convert pressure fluctuations into alternating voltage. All the energy is stored in a capacitor or microbattery—achieved via a rectifier and charge management circuit. Although these systems don't produce much electricity (tens of microwatts), they power leak monitors, occupancy detectors, and other low-duty-cycle sensors in noisy industrial settings.

Wearable and Biomedical Devices

Wireless power transmission from CSEM. (Image Credit: CSEM)

Wearables and biomedical devices are relying more on ambient energy to extend battery life or function without a battery. Typically, approaches involve thermoelectric harvesting, piezoelectric transducers, and flexible photovoltaic films. They feature low-voltage converters that harvest minute energy outputs, charging microcapacitors that power transmitters or sensors. This year, CSEM advanced research and development in self-powered wearable sensors via multi-source harvesting technology, such as thermal, photovoltaics, and wireless power transfer. CSEM also works with Swiss institutes for miniaturized and more efficient IoT and wearable devices.

Have a story tip? Message me here at element14.