IoT devices like a smart watch are powered by a battery or a supercapacitor. (Image Credit: fancycrave1/pixabay)

IoT devices typically use batteries as their primary source of power. But the type they use often depends on the application, environment, and energy requirements. For example, IoT devices rely on rechargeable (secondary) and non-rechargeable (primary) batteries. The non-rechargeable types, like Lithium Thionyl Chloride, are practical for difficult-to-replace or maintain applications like smart meters, remote sensors, and industrial asset tracking. They have a high energy density, a long lifespan (10+ years), and operate in wide temperature ranges.

On the other hand, more power-hungry IoT devices use rechargeable batteries, such as Lithium-Ion and Lithium Polymer. These types are ideal for communication and data processing in wearables, healthcare sensors, smart home devices, etc. Nickel-Metal Hydride batteries are sufficient for IoT devices requiring moderate power, as they have decent energy density and rechargeability.

Smart home devices use rechargeables for security cameras, thermostats, and other smart home devices. They also have nonrechargeable batteries for smart locks and other low-activity devices. Non-rechargeable batteries are commonly used for industrial IoT sensors for continuous operation in environments with vibrations and harsh temperatures. Rechargeables are perfect for wearables and healthcare devices as they can provide constant monitoring in a portable system.

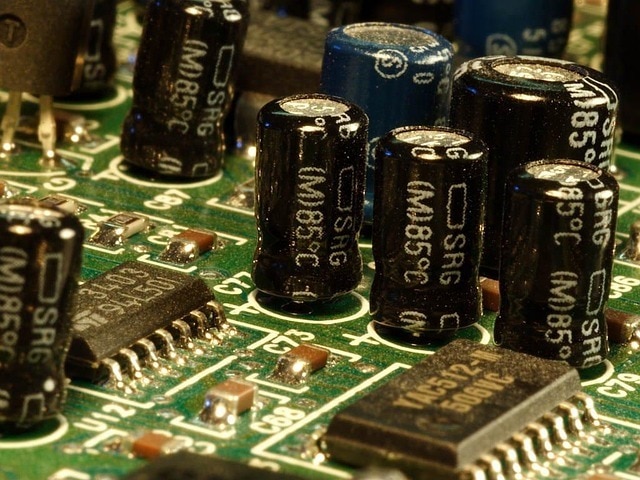

Capacitors integrated on a circuit. (Image Credit: PDPhotos/pixabay)

Supercapacitors are designed to store and rapidly release short, high-energy bursts in IoT devices for powering displays, sensing, and communication applications. This capability is achieved with minimal voltage drops and rapid recharging. They also collect energy from solar, RF energy, or other sources, effectively maximizing uptime.

Supercapacitors can supply backup power to IoT devices for data preservation if the power goes out or during peak loads. Due to their high energy density, long cycle life, and rapid charge, these are more suitable for applications like wearables, smart sensors, and devices in remote regions that require consistent power.

Lithium battery cells. (Image Credit: Alexei_other/pixabay)

Depending on device type, use conditions, and performance needs, batteries rely on different methods for charging. We often use wired charging for safe power delivery when an IoT device is connected to a charger. Lithium-ion and lithium-polymer batteries feature smart charging technology to control current and voltage to extend the battery life and make it safe for the user.

Charging starts with a constant current (CC) phase, which involves distributing a fixed current to the battery despite the voltage. While this occurs, the battery voltage slowly increases during the storage of energy via chemicals. This CC phase ensures rapid and efficient charging of the battery. Afterward, it switches to a constant voltage (CV) phase when the voltage reaches a threshold (approximately 4.2V for lithium-ion cells). While nearing a full charge, the voltage remains constant as the charging current decreases. This technique is safer for battery health since overcharging and lithium plating are less likely to occur.

Smart Battery Management Systems (BMS) monitor the charging state, temperature, and health of the battery. It also adjusts charging behavior for charging speed, safety, and longevity based on the device conditions. BMS controls the switching from CC to CV and stops charging when necessary.

IoT devices may also feature wireless charging capabilities. These typically involve inductive charging pads or sophisticated radio frequency power delivery. Inductive charging uses tightly-coupled electromagnetic fields between a device's receiver coil and a charging pad's transmitter coil. The device and charger must be correctly aligned and close to each other to charge. Loosely-coupled resonant charging and long-range wireless RF charging ensure a longer range and device position flexibility.

With long-range wireless charging, devices can be powered via energy delivery through the air without alignment or physical contact, significantly enhancing convenience in areas where it's impractical to plug in a device. The healthcare, industrial, and logistics fields benefit from wireless charging as it enables constant device functionality with very little human intervention.

Solar cells charge supercapacitors. (Image Credit: mb-bn/pixabay)

Low-voltage DC power supplies or energy harvesters like solar cells gradually charge the supercapacitors to power the IoT device during high demand. An energy management system efficiently transforms the collected energy into the voltage level a supercapacitor requires. Usually, a dedicated low-voltage DC-DC converter (charge-pump or buck-boost converter) manages the small, fluctuating voltage generated by energy sources. Charging then starts from 0V, maintaining a consistent current flow into the supercapacitor.

In this context, it is important to understand that supercapacitors serve as high-energy storage units with low equivalent series resistance (ESR). This allows them to efficiently store energy from low-power harvesters and deliver short, high-current bursts for IoT tasks like data transmission.

The charging circuit keeps the supercapacitor safe from overvoltage and blocks reverse current flow into the energy source. Since supercapacitors are like a short circuit at low voltages, charging circuits must handle high inrush currents effectively while maintaining efficiency.

We also use wireless power transfer to replenish supercapacitors. This method uses electromagnetic fields to deliver power to the supercapacitor’s receiving coil via a wireless charging unit. Placing the receiving coil within the magnetic field induces an alternating current according to Faraday's law of electromagnetic induction.

Then, the receiver circuit rectifies and regulates the induced current, supplying a stable DC charging voltage to the supercapacitor. This enables wireless power transfer to charge supercapacitors without physical contact, which is ideal for compact IoT devices requiring recharging.

People expect long-term reliability for batteries or supercapacitors powering IoT devices like a stopwatch. (Nik/Unsplash)

Consumers using batteries to power their IoT devices expect reliability, low maintenance, and longevity. Most are installed in hard-to-reach places or remote areas, which means owners want to use batteries for years without needing a replacement. People benefit from this as it ensures lower maintenance costs and downtime, essential for large-scale IoT networks.

When it comes to batteries, people also want optimal energy efficiency. The IoT device's power management system should function with batteries, ensuring it uses less power. This is ideal as IoT devices usually run in low-power sleep mode, activating for a short time for sensing or data transmission.

We try to look for and use batteries featuring high capacity and a good form factor. After all, they must fit inside compact IoT devices without sacrificing energy storage capacity, which balances size and functionality. Rechargeable batteries or those that can work with energy harvesting technologies are often preferred for sustainability and low maintenance.

People also have expectations for supercapacitors and their durability. In this case, their ultra-long cycle life enables them to survive millions of charge/discharge cycles, outlasting batteries that degrade after thousands of cycles. This means IoT devices last longer as they don't need regular replacements or maintenance.

In addition, supercapacitors deliver power bursts for sensor activation or data transmission. That rapid power delivery is what makes supercapacitors more unique compared to standard batteries, allowing them to reach peak power demands with zero delay.

Supercapacitors are more robust, too. They remain operational while maintaining stable performance in harsh temperatures (-40°F to 185°F). IoT devices can last longer in those environments, whereas batteries would usually fail or degrade rapidly. Not only that, but supercapacitors are safer as they don't rely on chemical reactions for energy storage, preventing thermal runaway and other risks.

Personally, I like the idea of using supercaps in IoT or remote sensor based projects. The charge cycle time is faster and they theoretically have a longer service life. If the devise footprint is no issue, go caps. If it is, batts.

Have a story tip? Message me here at element14.