(Image Credit: ScienceDirect)

Battery technology is advancing, and a new type, solid-state batteries (SSBs), is expected to emerge in the upcoming years. Researchers at the University of California, Riverside, published a review highlighting the potential and drawbacks of solid-state batteries.

A solid-state battery is a rechargeable battery made of solid electrolyte (like ceramics, sulfide-based compounds, or polymers) rather than a liquid or gel electrolyte in lithium-ion types. SSBs function similarly—the electrolyte passes ions between the cathodes and anodes for a quick recharge, taking only minutes compared to an hour for lithium-ion batteries. Thanks to those solid materials, the anode can be made of pure lithium metal, an extremely thin layer holding more energy per gram than graphite anodes. This results in a longer lifespan, higher energy density, and a lighter build.

Lithium-ion batteries degrade after 1,000 charge cycles, while SSBs retain 90%+ after 5,000 cycles. Batteries may last 15-20 years in this scenario, giving EVs more than double the lifespan.

When charged, SSBs hold two to ten times more capacity than lithium-ion batteries. This design prevents thermal runaway and leakage from occurring, while addressing other safety hazards associated with liquid electrolytes.

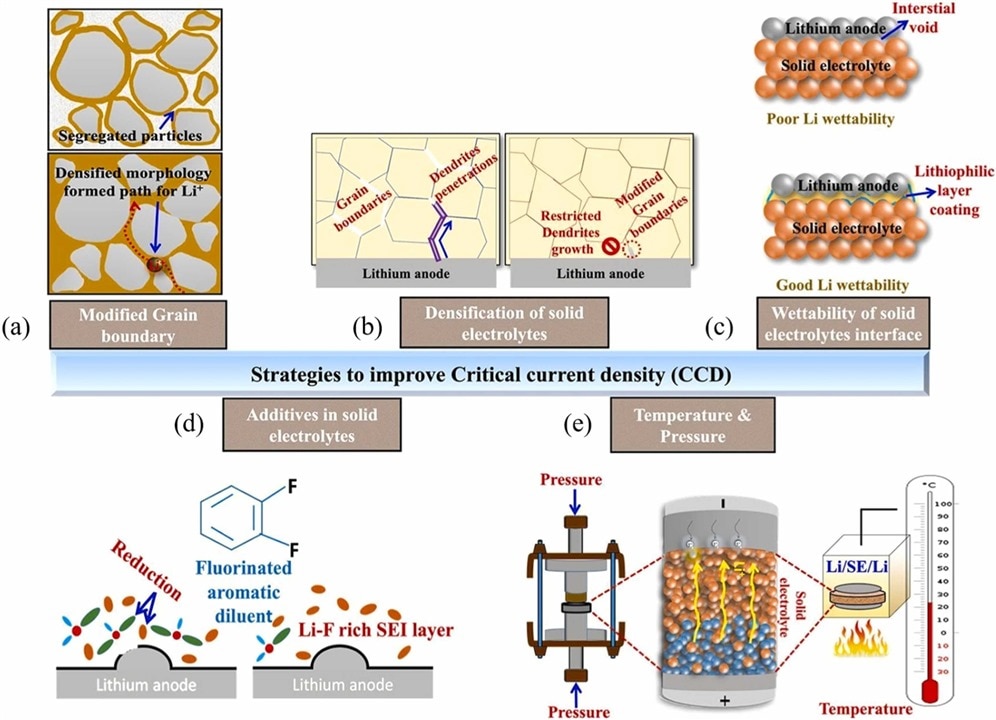

SSBs also excel at charging times, taking only 3 or 12 minutes to reach 80% charge. That's a big boost compared to the 30-45 minutes it takes for the lithium-ion batteries. Additionally, battery performance and safety are constrained by its critical current density (CCD), which represents the maximum rate at which the battery can safely accept charge. Solid-state batteries are behind in CCD compared to lithium-ion, as they have lower ionic conductivity and interfacial resistance. Technological advancements are addressing it.

Methods to improve CCD in SSBs. (Image Credit: ScienceDirect)

For instance, sulfide-based solid electrolytes have emerged, offering ion delivery speeds comparable to liquid electrolytes. According to the paper, compounds such as LGPS feature conductivities reaching 12 mS/cm. Solid-state cells operate at lower temperatures, enabling installation without a large cooling system. This means they'll be lighter and use up less space, which is advantageous for EV and aerospace applications.

Now that solid-state battery technology is advancing, the future looks promising for energy storage across many industries, including consumer electronics and electric vehicles. Within the next few years, SSBs could enter commercial applications. Between 2027 and 2030, mass production is expected to begin. By 2030, SSBs could become more mainstream, powering a projected 10-15% of new electric vehicles and 20-30% of consumer electronics.

Companies such as QuantumScape, Solid Power, Samsung SDI, Nissan, Volkswagen, Toyota, and Hyundai are driving advancements in solid-state battery technology. Toyota plans to launch an SSB-powered EV by 2027, while Nissan targets a 2028 release. Samsung SDI will start mass-producing solid-state batteries in 2027. Qing Tao Energy reports current production at 100 MWh/year, with plans to scale to 10GWh. The UC researchers developed a roadmap to accelerate commercialization, emphasizing manufacturing improvements, interface optimization, and the use of advanced diagnostics to better understand material behaviors.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell