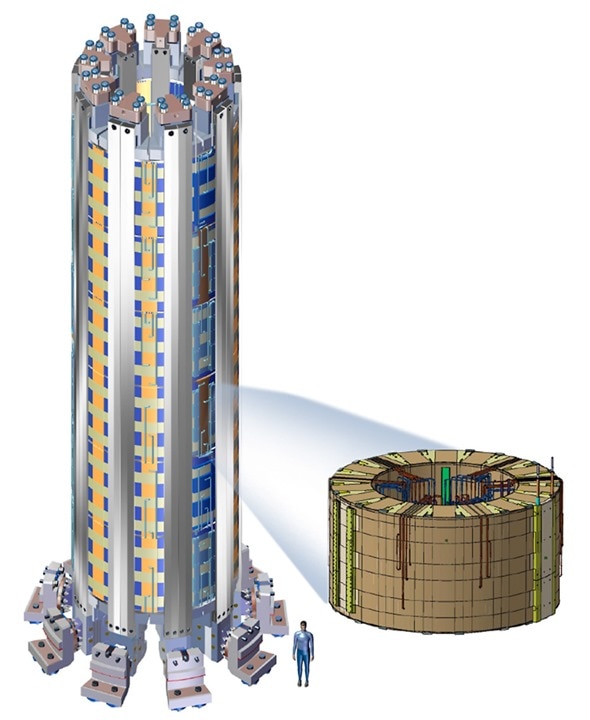

The US recently delivered the central solenoid to the ITER site in France. (Image Credit: General Atomics)

The ITER project, an international partnership, is getting closer to achieving nuclear fusion, an effort that involves the replication of the power of the sun. The US recently transported the central solenoid, a 59-foot superconducting magnet, to the ITER project site in France. This massive component is designed to initiate and sustain the plasma for nuclear fusion processes.

The central solenoid’s origins are traced back to the history of the ITER project, which started in the late 1980s to drive fusion energy. In 1986, the United States collaborated with Japan, the European Union, and the Soviet Union to design a large fusion. With this partnership, the ITER conceptual design began in 1988, which set the stage for the development of the central solenoid.

Designing and manufacturing this crucial component began with a multi-year partnership between engineers at General Atomics and US ITER experts. General Atomics developed the special tools and processes for the superconducting magnet. In 2015, fabrication of the modules began at General Atomics’ Magnet Technologies Center in California.

Individual modules feature approximately 3.6 miles of niobium-tin superconducting cable, and each module requires more than two years of precision manufacturing. These modules underwent rigorous testing, including exposure to cryogenic temperatures, to ensure they can function in the harsh environment of a fusion reactor.

In 2019, General Atomic completed the first module, which underwent testing before being sent to France in 2021. Its journey started by road to the port of Houston, shipment across the Atlantic before reaching its destination at the ITER site in southern France.

One of the six modules for the central solenoid. (Image Credit: General Atomics)

The central solenoid contains six individual magnetic modules, and each one weighs approximately 266,800 pounds. It comes with a rigid support structure called the magnetic exoskeleton that keeps the solenoid intact while generating intense forces during nuclear fusion. Principal engineer at Oak Ridge National Laboratory David Vandergriff says the solenoid would not be able to function without the support structure.

Eight US companies were involved in constructing the central solenoid’s support structure. Superbolt helped develop the technology to ensure the assembly stays intact under extreme forces. Designing the 27 vertical connectors (tie plates), which serve as the cage’s central core, proved challenging. The connectors join the upper and lower foundation blocks together, forming a rigid framework housing the solenoid.

According to Freudenberg, an engineer who worked on the project, creating the tie plates in an individual piece was a difficult task. The bars, measuring 49 feet long, had to comply with exacting tolerance specifications and remain straight. To attain that precision, the team collaborated with specialized forges, reflecting the drive behind the ITER project.

So far, four out of the six modules have already been integrated at the ITER site. The other two will be complete by the end of this year. Installing the central solenoid is a big step forward in the ITER project and brings humanity closer to an operational fusion reactor by 2040. Completing this step enables more systems and components to be installed.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell