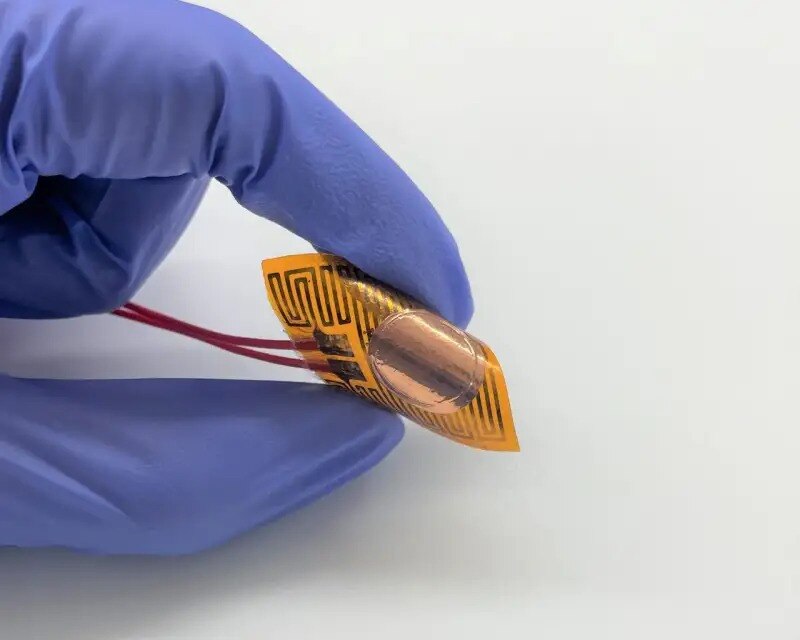

The flexible material improves thermal transport within a device. (Image Credit: Carnegie Mellon University, College of Engineering)

Smaller and more powerful devices have a greater risk of overheating and burning out. Although cooling solution technologies have progressed, thermal transport between the chip and cooling system remains a barrier because of the materials' roughness. Carnegie Mellon University researchers created a flexible, powerful, and extremely reliable material to address that issue.

"At first glance, our solution looks like any ordinary copper film, but under a microscope, the novelty of our material becomes clear," explained Lin Jing, Ph.D. student.

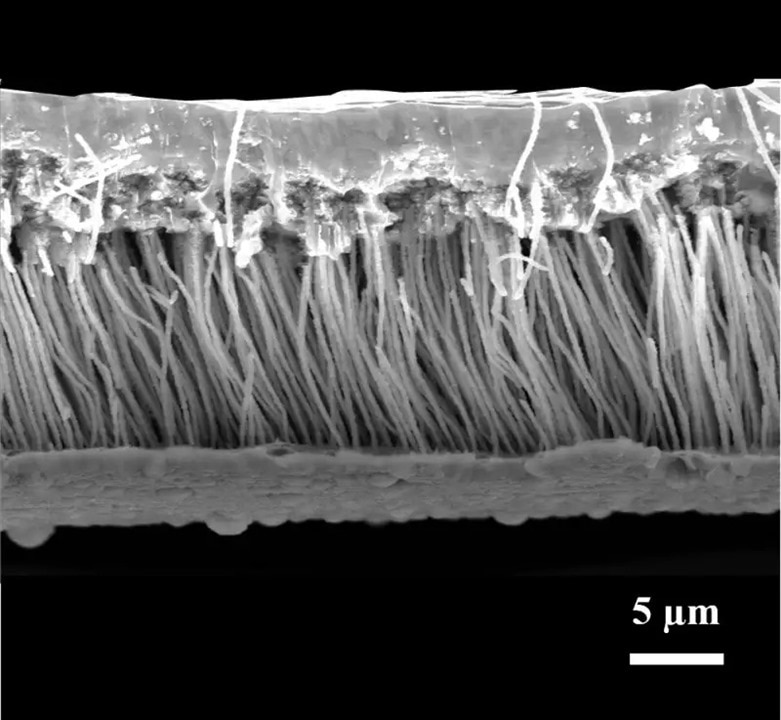

The team's material is user-friendly and made of two thin copper films featuring a graphene-coated copper nanowire array in the middle. "Other nanowires need to be in-situ grown where the heat is designed to be dissipated so that their application threshold and cost is high," said Rui Cheng, a postdoctoral researcher. "Our film isn't dependent on any substrate; it is a free-standing film that can be cut to any size or shape to fill the gap between various electrical components."

This sandwich builds off the supersolder created by Sheng Shen, a Professor in the Department of Mechanical Engineering at Carnegie Mellon University. The supersolder is a thermal interface material (TIM) that has double the thermal conductance of advanced TIMs.

The team boosted the supersolder's thermal transport by coating it with graphene, which also prevents oxidization risks and increases longevity. Compared to the thermal adhesive on the market, the sandwich decreases thermal resistance by over 90% with a similar thickness.

A scanning electron microscope captured this cross-section image of the material. (Image Credit: Carnegie Mellon University, College of Engineering)

Due to its high mechanical flexibility, the sandwich can work in flexible electronics and microelectronics, such as flexible LEDs and lasers for display and lighting, wearable sensors, soft robotics, and implantable electronics for monitoring health. Next, the researchers plan to explore how they can make the material perform better, be more affordable, and scale it at an industrial level.

"We are very excited about this material's potential," Shen said. "We believe that a wide variety of electronic systems can benefit from it by allowing them to operate at a lower temperature with higher performance."

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell