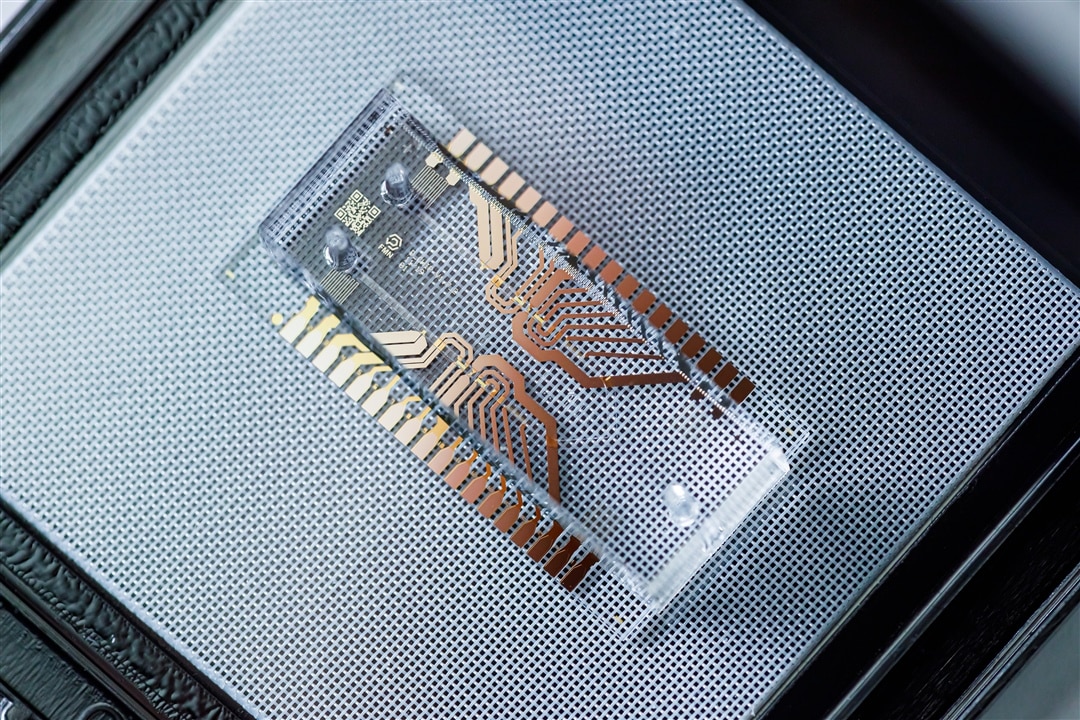

The microfluidic chip is a lab-on-a-chip device that can be used to detect diseases or check the patient’s compatibility with drugs. Image credit: Wikipedia)

Lab on a Chip (LOC) is described as a microfluidic device that integrates one or more laboratory functions on a single IC that ranges in size from a few millimeters to several centimeters based on the application. Think of them as fluidic integrated circuits, where tiny liquid samples (less than picolitres) flow through microchannels etched into the device that allows for mixing and separating fluids, performing chemical reactions and analyzing substances. These tiny LOCs make it possible to perform those screenings in the field without the need for a full-blown lab.

LOCs can be traced back to the MEMS (Microelectromechanical Systems) era in the mid-1980s, but they weren’t fully realized until the 1990s when advancements in microfabrication and microfluidics were made. The integration of microchannels, pumps and sensors on silicon or polymer substrates allowed researchers to manipulate fluid on microscopic scales. Early types of LOCs were designed for analytical chemistry and DNA applications, but they would eventually rise to become an integral part of the medical industry over the next two decades.

By the late 1990s, LOC research gained an economic boost from the US military and DARPA, who saw interest in portable systems to detect chemical and biological warfare. A decade later saw the rise of LOCs in the medical field, with breakthroughs in point-of-care (POC) devices that could test for diabetes, cardiovascular issues and infectious diseases. For example, glucose monitoring for people with diabetes became more accurate and less painful, allowing for better health management. By the mid-2000s, interest and innovations in LOCs skyrocketed with a growing interest from companies and research groups looking to use the technology for environmental monitoring, chemical analysis and synthetic chemistry applications.

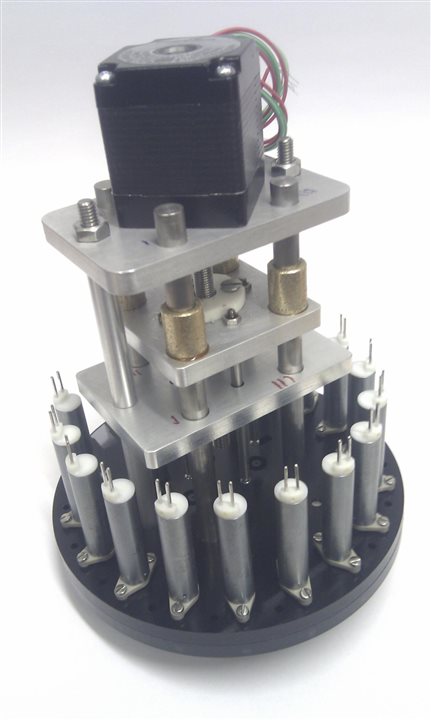

NOC engineers designed the LOC nutrient sensor to take measurements of nutrient concentrations in the Southampton Water Estuary. (Image credit: National Oceanography Centre)

Today, LOCs can be found in a myriad of industries, including oceanography, where researchers from the National Oceanography Centre (NOC) are using the devices to get a better understanding of the planet’s changing seas. Engineers at NOC have more than 10 years of innovation when it comes to designing LOCs for chemical oceanography. In 2011, they designed the first successful LOC nutrient sensor deployed in the Southampton Water estuary in 2011 and 2012. The LOC was equipped with nitrate and nitrite sensors, which used microfluidics and chemical analysis techniques to make high-quality in situ measurements of nutrient concentrations.

The NOC engineers would continue to develop their LOC sensor for additional aquatic applications, upgrading the sensors for deep sea deployments while equipped on a Kongsberg Seaglider to collect nitrate profiles in the Celtic Sea. Their LOC sensor would find its way to the US, where the engineers took part in a high-profile international competition to develop pH sensors to measure changes in acidity, and eventually to the Arctic for a year-long deployment.

The LoCKBath LOC device can produce lab-quality results in just a few minutes. (Image credit: University of Bath via NIH)

The pandemic saw the rise of mobile virus detection devices, with some testing breath samples while others being equipped with image sensors to detect heat elevations in an effort to keep the virus from spreading. LOCs were designed for COVID-19 detection as well, along with other pathogens and even cancer.

Engineers at the University of Bath developed what they termed “The world’s fastest COVID test” that’s capable of detecting the virus within 3 minutes and producing lab-quality results. Known as LoCKAmp, the LOC device functions by rapidly releasing and amplifying genetic material taken from a nasal swab sample, then subjecting it to a chemical reaction to produce a result, which can then be viewed on a smartphone app. Unlike lateral flow assay tests used in traditional COVID tests, LoCKAmp takes advantage of genetic-based testing techniques normally reserved for lab-based PCR (Polymerase Chain Reaction) tests.

What makes the LoCKAmp unique from other LOCs is that it was designed using off-the-shelf parts and factory-produced PCBs rather than silicon or polymer substrates. Choosing the PCB material would allow the LOC device to be mass-produced in much the same fashion as any electronic circuit board and with lowered costs. What’s more, the engineers state the LoCKAmp could be deployed at the community level by monitoring wastewater to detect viruses, allowing medical professionals to track infection rates.

These are just a few examples of the latest innovations of LOC technology since its inception in modern form, making these devices more accessible and cost-effective. Research into paper-based microfluidics and 3D printing will further reduce those costs, while engineers are looking at ways to develop wearable LOCs for active health monitoring. As the technology continues to evolve, its impact on science and society will eventually make them an indispensable part of our daily lives.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell