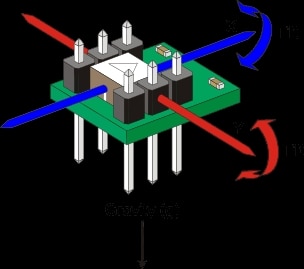

An IMU-MEMS sensor. (Image Credit: Gladiator Technologies)

The research and development of MEMS (Micro-Electro-Mechanical Systems) technology started in the 1960s. It has seen commercial adoption and industry growth since the 1980s, accelerating in the 1990s and beyond. They've changed how sensors work in the real world. These tiny devices feature a combination of mechanical and electronic components on a tiny chip—achieved through semiconductor manufacturing techniques.

Sensors used to be much larger, fragile, and more expensive, and were only practical for aerospace, defense, or certain other industries. Gyroscopes were the size of a soda can and cost thousands of dollars, making them impractical for consumer devices. All of that changed with the introduction of MEMS, which made sensors more affordable, smaller, and less power-intensive. This occurs because MEMS utilizes the same semiconductor processes (etching, thin films, sacrificial layers) as microchips, enabling the fabrication of mechanical structures, such as beams, diaphragms, and proof masses, on silicon wafers. These structures are often integrated with monolithic or tightly coupled ASICs for readout. This meant pressure sensors, accelerometers, and gyroscopes can be miniaturized to chip-scale form factors and manufactured at scale for a few dollars. Sensors were made smaller and more accessible. With those qualities, MEMS is now integrated into all sorts of products, including fitness trackers, medical implants, smartphones, appliances, and other devices.

Three-axis accelerometer. (Image Credit: GlobalSpec)

MEMS then went from expensive to mass-produced. Custom-built sensors had a higher cost and were fabricated in low volumes, usually with low yields. Refining processes and investing in MEMS labs increased yields to a similar level as advanced ICs.

Thanks to semiconductor-style batch manufacturing (millions of identical dies fabricated on single wafers), wafer-level testing, and conventional lithography and etching processes, prices were significantly reduced. This meant fabricating millions of sensors—ideal for installing multiple in one device. Scaling up sensor production transformed sensing from a luxury into a commodity, which drove the growth of consumer electronics, automotive safety systems, and smart devices relying on multiple integrated sensors.

Sensing evolved from single-purpose to multi-modal. Usually, sensors would measure one parameter, like pressure or acceleration. Now, they measure physical activity, orientation, air quality, presence, occupancy, fluid flow, and micro-gestures.

MEMS enabled the integration of multiple sensing modalities in one package—combined with built-in signal processing capabilities. In this case, gyroscopes, magnetometers, and accelerometers work together with inertial measurement units (IMUs), capturing complete movement and orientation. Similarly, environmental modules integrate pressure, temperature, and humidity sensing in a device. That means one sensor placement provides richer data and better context, making designs simpler while expanding the range of measurable conditions.

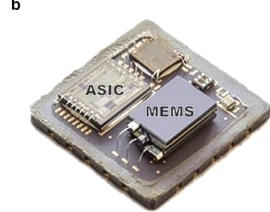

MEMS integrated with ASCI. (Image Credit: Microsystems & Nanoengineering)

Co-integrating MEMS mechanical structures with ASICs adds analog-to-digital converters (ADCs), low-noise analog front ends, calibration tables, and digital signal processing (DSP). Error sources are also reduced thanks to firmware-based real-time sensor fusion, package-level co-location, and mechanical-electrical coupling.

MEMS also enabled sensors to operate from passive to always-on. Sensors consumed lots of power and required host system intervention for activation or data processing. In comparison, MEMS sensors don't need as much energy, allowing constant monitoring and real-time event detection without constant active processing.

They feature built-in event detection and threshold interrupts, ensuring less reliance on the host processor. MEMS designs are used in earbuds that pause when removed, wearables that monitor our sleep, and phones that wake when picked up. Sensors can be installed in battery-powered or remote regions, which require constant observation under limited power.

Always-on is possible as mechanical MEMS structures have high signal-to-noise ratios combined with extremely low-power ASICs supporting advanced power management methods like duty-cycling, wake-on-motion, and threshold-triggered interrupts.

Lastly, the final shift involved moving from isolated to connected ecosystems. Sensors would operate as an independent instrument that provided data when prompted. With MEMS technology, small networks of low-cost, low-power sensors can connect through standardized interfaces and be paired with edge processing. Rather than one measurement point, sensing is now transmitted across entire environments. This ranges from smart buildings and factories to cities and natural landscapes.

It leads to a wider spatial and temporal coverage—continuously sampling many sensing points. On-sensor preprocessing reduces data bandwidth and extends battery life. Meanwhile, standard digital interfaces (such as I²C and SPI) and edge microcontrollers enable a simpler design and connectivity. Additionally, MEMS sensors can interpret data, improving system efficiency, thanks to embedded AI and machine learning advancements.

Applications of MEMS sensors.

MEMS isn't a new technology. It's already incorporated in many devices, including smartphones, medical wearables, and vehicles. Nowadays, there's a lot about it changing, like the scale and depth of their use. In the next-gen of MEMS adoption, we will see MEMS expanding into more widespread, high-impact deployment—a shift from early-stage applications.

In the health industry, MEMS is powering various devices, such as fitness trackers and glucose monitors. Now, we're seeing scaling opportunities for implants and clinical systems. MEMS network sensors can be used to monitor cardiac activity (implantable pressure sensors) or track medication delivery via smart pills. Although the technology exists, the next step involves introducing it to broader populations, shifting healthcare delivery and monitoring. AI and IoT network integration enables real-time data analysis, early disease detection, and patient engagement.

In addition to tire pressure monitoring and stability control, the airbags in cars also use MEMS. They’re expanding in this field for autonomous driving and advanced driver assistance systems (ADAS) for vehicle safety and navigation. If GPS signals become unavailable, MEMS accelerometers and gyroscopes take over as a backup navigation system. Those instruments also behave like stability inputs in automated safety decisions, including collision avoidance, lane keeping, and emergency braking. MEMS' small size, high precision, and low power consumption allow their integration in vehicles, supporting sensor fusion and real-time control demands.

Air quality, water quality, and even building vibrations are being measured with MEMS systems. We're deploying citywide networks of MEMS sensors at scale to input real-time data to municipal systems. Cities will then be able to manage pollution levels, optimize traffic, improve energy efficiency, and prioritize infrastructure maintenance based on sensor data. This is all thanks to MEMS systems featuring a combination of durability, compactness, and low-cost qualities, which are required for deploying thousands of sensors across an urban environment. Sensor sensitivity and selectivity advancements enable MEMS devices to detect trace pollutants and slight structural changes for early warning and smart city initiatives.

Wearables, tablets, and smartphones feature MEMS accelerometers and gyroscopes. Now, the focus is on making interfaces more immersive and interactive, driven by improvements in MEMS miniaturization, precision, and low power consumption. AR/VR headsets use MEMS technology for precise head and motion tracking, leading to more realistic and responsive virtual experiences. While the technologies evolve, MEMS will increasingly power gesture recognition, spatial computing, and smart home ecosystems to support user interfaces and context-aware environments.

Have a story tip? Message me here at element14.

-

DAB

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

DAB

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children