Hello everyone. Today I completed something small but great at once. I first time successfully soldered extremely small sensor - Maxim Integrated MAX31875 I2C temperature sensor. This is sensor is provided as part of MAXESSENTIAL01 Sample Kit which you can receive with corporate or scholar email as a free sample totally for free from Maxim. I did not consider using this sensor in project because I realistically thought that it is impossible to solder in hand and all my projects are soldered in hand. But for fun I designed small breakout PCB, order it at OSHPark for 0.55 USD and tried to solder it.

This sensor has only 4 pins (2 power wires GND and VCC and 2 I2C wires SDA and SCL). It is packed in WLP4 which is kind of package with balls at the bottom. WLP stands for Wafer Level Package and as you guess, chips on wafer are small, so this package is also very small. Package size is only 0.837mm × 0.837mm which is less than milimeter.

And really, chip is extremely small. Reading package marking is totally impossible even when using magnifying glass. All following photos are taken by iPhone magnifier tool at maximum possible zoom.

Breakout

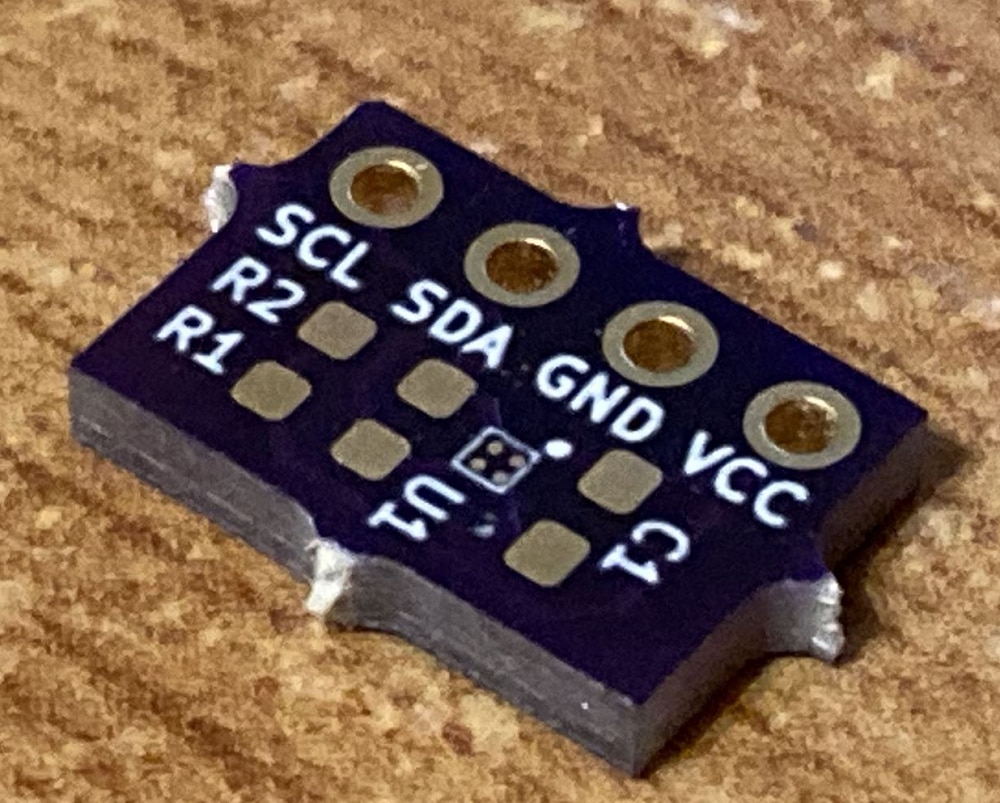

This is breakout board to which I attempted to solder sensor:

Now you see it extremely zoomed. For reference I recommend taking one 0603 resistor or capacitor to the hand and compare. At the middle you can see highlighted place for MAX31875. As you can see whole temperature sensor is as large as (only) one pad of 0603 footprint! It is smaller than it’s own decoupling capacitor.

Applying Solder Paste

As a next step I applied solder paste. I had no stencil, so I attempted to cover chip area by thin layer of solder paste. Area is very hard to see by eye, so I had to use iPhone magnifier at maximum zoom to check paste application and attempt to clean paste from outside of sensor footprint and reduce thickness of layer. At end it looked as follows:

Then I placed a chip to the area. But…

Where is the pin 1 marker?

Find marker of pin number 1 is usually easy, but on chip with sizes less than millimetre it definitely is not. According to documentation pin marking should be in the corner and four letter marking should be at center. But even at maximum zoom of my iPhone camera (aka hobby grade microscope) I see only following glyphs:

As you can see there is no glyph in the corner. But there is something which looks like Q od D letter and some mark at next to this letter. I had no idea if this is pin 1 marker or pin 1 marker is at the corner, and it is too small for capturing with this camera. But I guessed that symbol near letter is pin 1 marker and assumed that pin 1 is at nearest corner:

I placed chip on the board, but unluckily I rotated it when manipulating, so I had to rotate it by 90 deg on the board. Because of small layer of solder paste applied before it was possible to rotate it, but definitely I must say that is not easy to rotate this kind of chips by 90 deg.

After placement I started hot air gun and start heating the board and the sensor. Of course, when doing this I violated absolute maximum rating about temperature and possibly I affected reliability and accuracy of sensor. When soldering at some moment solder paste became bright which I noticed by eye. I also noticed that sensor fit and changed a location a little. At this moment I stopped heating it and wait until temperature of board decrease. Then I tested ESD diodes on pins by multimeter. Diodes between GND and VCC and GND and SDA looked working. I also tested short circuits, but I was unable to sense any connectivity between SCL pin and other wires. I also noticed that after soldering sensor is askew and most probably SCL pin is flaying, and it is not connected to the board .

For resolving this issue, I started hot air gun again, heated the sensor again and I tried to push corner containing SCL pin to the board. Of course, my hands are not as precise as required so I moved the senor more than I want and had to reposition it again, but after few attempts it looked good, so I stopped heating and try procedure with ESD diodes test again. Luckily, I sensed ESD diodes on all pins including SCL and I did not measured any short circuit between pins.

I2C Scan

Before I soldered remaining components (decoupling capacitor C1 and I2C pullups R1 and R2) I connected pull-ups on breadboard and touched wires from Raspberry Pi to the board. I started i2cdetect and I successfully detect MAX31875 on the bus! It works!!!!

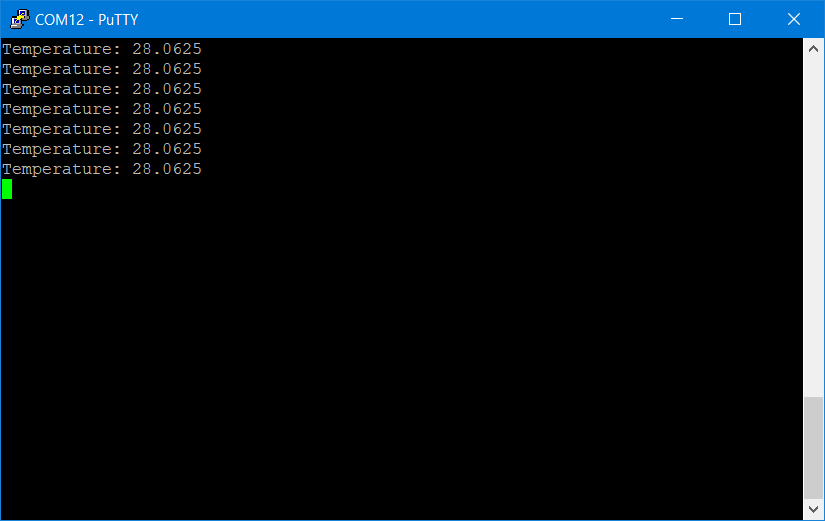

After this success I soldered remaining components and pinhead, connected sensor to Cypress PSoC 62 board which is not utilized by any project at this time, wrote simple library and simple program for printing temperature measured by this sensor:

Temperature looks correct, but as I have said above. I don’t know if my double-attempt soldering with violating absolute maximum ratings duration affected sensor accuracy. Later I improved my library and tested advanced features like over-temperature detection and hysteresis. All features of this simple chip works well.

Top Comments