Note: See here for a project that resulted from this discussion: BLE EasyTempProbe

Hi,

Since thermocouple measurement ICs are getting expensive/hard to find, I wished to use a single channel ADC, for thermocouple measurements (actually, I want to use a dual channel ADC for two thermocouples, but it's likely the same problem just doubled!).

The trouble is, the cold end of the thermocouple needs measuring too, and I was thinking of using a thermistor for that because that's easier to obtain (and cheaper) than an IC sensor. In summary, I wished to multiplex a thermistor and a thermocouple.

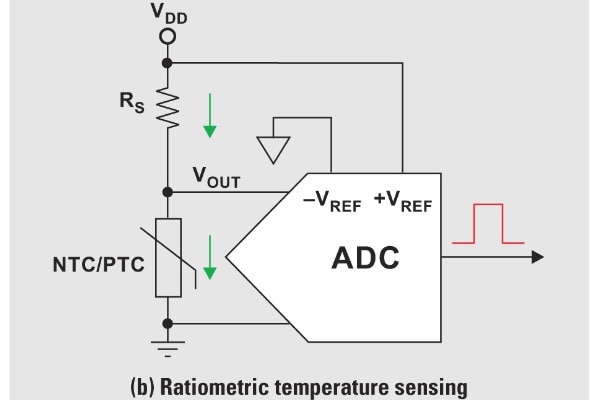

I've come up with the diagram below so far and wish to use it in an environment where the cold junction might be in the range of -40 to +50 deg C, and the thermocouple might be in the range of -40 to +400 deg C (maybe a Type J thermocouple). I think it will have an error of a few deg C. The ADC is 16-bit, and I likely won't be using the whole range of it. The ADC has a PGA of up to 8X, so it will be set to 8X when measuring the thermocouple.

The main benefit of the proposal below is that it is cheap since it just needs a couple of transistors and a few resistors. I could think of more complex circuits for a more accurate measurement, but it would be nice to see if this is good enough, or if it could be tweaked to be good enough unless anyone has other suggestions.

If it works, this would be a cheap way (under $5, ADC included) to have two thermocouples each with their own compensation, with the drawbacks that accuracy might be a few degrees at best, and no isolation either, unfortunately.

Any ideas would be gratefully appreciated, since I'm sure I may be missing some great techniques, missing the wood for the trees, etc! Has anyone come across any low-cost methods to do such a thing? Any mistakes I'm making?