Introduction

When measuring low-noise circuits, it can become necessary to shield the circuit boards! Otherwise, nearby electric fields or electromagnetic radiation could affect the measurements.

A cheap way that many engineers use is to repurpose any old biscuit/cookie tin! After having done this a few times in the past, I wanted to share some suggestions.

Choosing a Box

Ideally the box should be large, since it is very easy to run out of space with boards and cabling inside there.

The photo above shows two boxes; the one at the bottom is a better size.

Choosing Connectors

BNC and SMA connectors can be convenient to use. It’s personal preference mainly. I have a lot more SMA cables than BNC, so I tend to use more SMA connectors! They can be cheaper too.

The photo above shows some example chassis-mount SMA and BNC connectors. The one on the right is isolated from the chassis which may be occasionally required. The one more likely to be used is shown in the center of the photos. You could also use chassis-mount back-to-back SMA or BNC adapters if desired.

For power entry, a very decent way is to use a component called a ‘Feed-Thru’, which is a cylindrical capacitor with one conductor being the cylinder, and the other conductor egressing axially from both ends.

(Image source: cpc.farnell.com)

(Image source: cpc.farnell.com)

Preparing the Enclosure

Holes

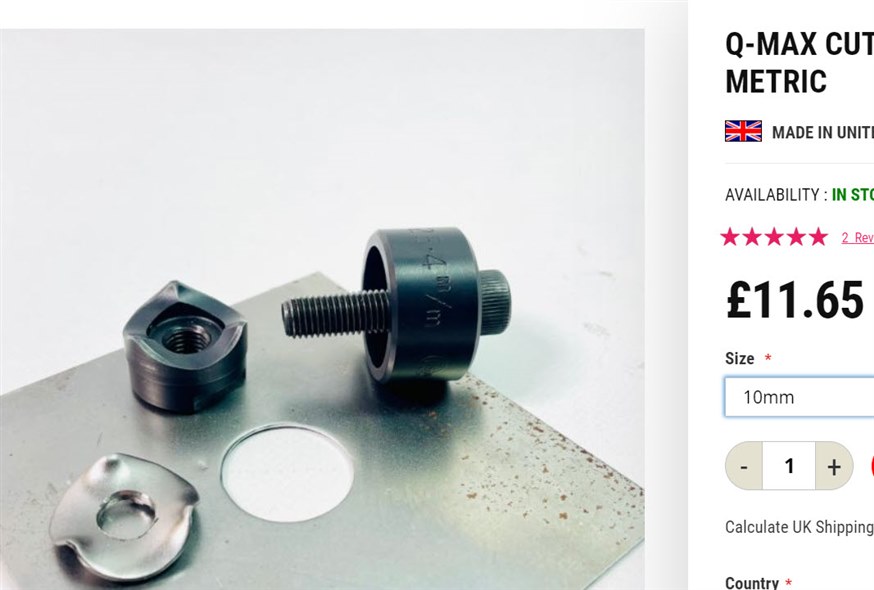

One technique is to use small quick-clamps to place a block of wood on the inside of the box, carefully of course while avoiding damaging to the lip of the box in the process. Then, a drill can be used without deforming the enclosure too much. The large box in the photo above used that technique. For the smaller box in the photo, I used hole punches. For standard chassis-mount BNC connectors, a Q-Max 10mm Hole Punch works great.

(Image source: stakesys.co.uk)

(Image source: stakesys.co.uk)

For most standard SMA chassis-mount connectors, a 6.4 mm punch is desired. The hand punch kit in the photo below works fine; it comes with a range of punches, and there is a 6.35 mm one which is suitable.

(Image source: zoro.co.uk)

(Image source: zoro.co.uk)

An advantage of the punches is that you can rapidly make a 'hole' load of shielded test boxes for all your work colleagues.

Dealing with Coatings

Metal biscuit/cookie tins usually have paint on the outside, and also a thin non-conductive coating on the inside. That means that the lid won’t be electrically connected to the box, and connectors won’t be electrically connected to the box either : (

The technique which worked well for me was the following. Using a high-speed tool (e.g. Dremel) and a wire brush on the end, it is possible to easily remove paint. You’ll definitely need eyewear and a mask, because of all the dust. The photo here shows where the paint was required to be removed, in order for the lid to make electrical contact.

Similarly, the coating on the inside of the box needs removing too, in the areas where the holes were made.

The lid needs a bit of work too on the inner part of the lip. The wire brush method was difficult here. Sandpaper is easier for this part.

That is it pretty much..You’ll need 12mm and 8mm spanner/wrench for tightening the BNC and SMA connectors. I used a dab of glue as well to prevent them from rotating.

Using It

Here’s a photo of it in use. Although the base has a thin insulated coating, this is clearly insufficient, so a piece of card or other material is required.

Although not ideal, I used the BNC connector for power entry in this case. Ferrite cores are handy to have around as well (either like the ones in the photo below, or the clip-on variety [known as ‘Split Core’]), since they will help reduce high-frequency noise entering the enclosure. Twisted wiring is also extremely useful, so that any noise that does get picked up from the environment is common-mode (i.e. near-identical on both wires).

Useful Parts

BNC chassis socket MP-13-25-12 TGN

SMA chassis socket 132291

Steel brush attachment Dremel 530

Ferrite cores: 2631665702 and 742701703

Ferrite Split Core: 431164951.

Feed-Thru: 2499-003-X5U0-102PLF

Feedback!

It would be great to see other people’s test enclosures since it is possible to glean many ideas from them. If you don’t mind taking a photo, it would be awesome if you could show it!

Thanks for reading!

-

Andrew J

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to Andrew J

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

Andrew J

in reply to shabaz

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

beacon_dave

in reply to Andrew J

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

shabaz

in reply to Andrew J

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

shabaz

in reply to Andrew J

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children