Detailed review of the current shunt circuit of the Programmable Electronic Load.

The circuit and measurements are discussed here. |

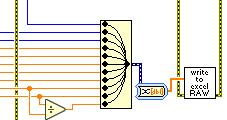

Circuit

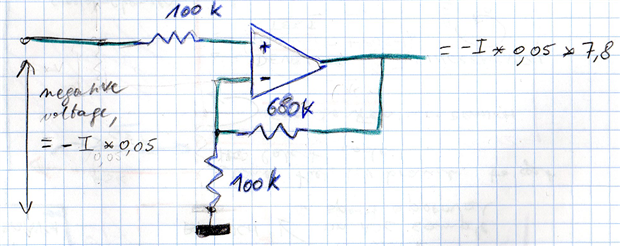

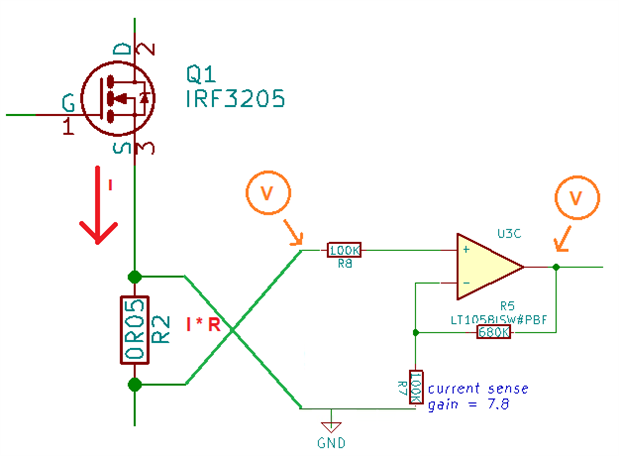

The current measurement circuit reads the voltage over a 50 mΩ shunt resistor that's in series with the load circuit.

That voltage (always negative, because the resistor is "below" the circuit's analog ground) is amplified by a non-inverting OpAmp circuit, with gain 7.8.

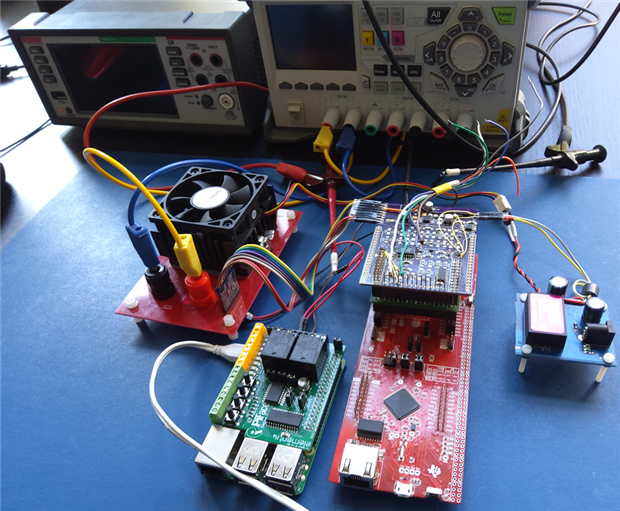

Test Setup

A DMM measures the voltage of the shunt and the output of the OpAmp. Both relative to that analog ground.

The measurement is automated.

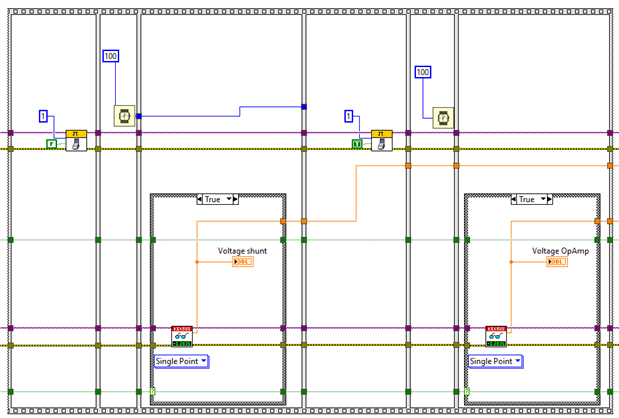

At every iteration, the shunt voltage and the output of the OpAmp are logged.

A relay switches the DMM probe between the two measurement points.

Automated flow detail: switch DMM probe, then take a sample.

I've also added a gain calculation.

Gain is calculated as the ratio between output and input. Then logged.

Measurement Results

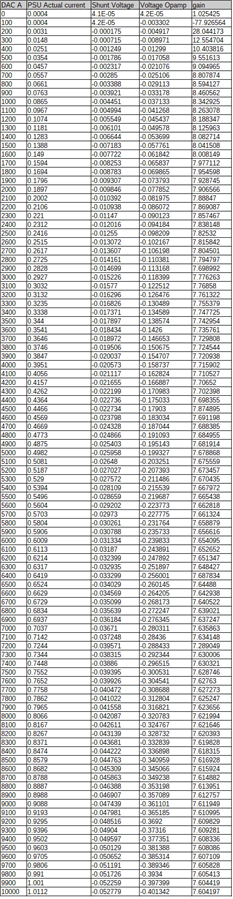

All data is written to the attached spreadsheet.

The extract below shows 101 measurements.

The DAC that controls the eLoad is set to 0.

A first measurement of current (I take that from the PSU), shunt and OpAmp output voltage are written.

Then, the DAC is 100 times increased, each time with 100. ANd the measurements are repeated.

The attached version (9.xlsx) has more measurements (All eLoad ADCs, and some more stats from the PSU).

101 samples. PSU = 5 V, DAC initial = 0, steps 100, step 100

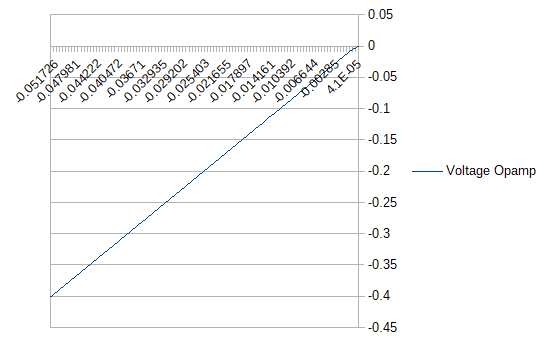

Here's a graph of the output vs input. The line represents the gain.

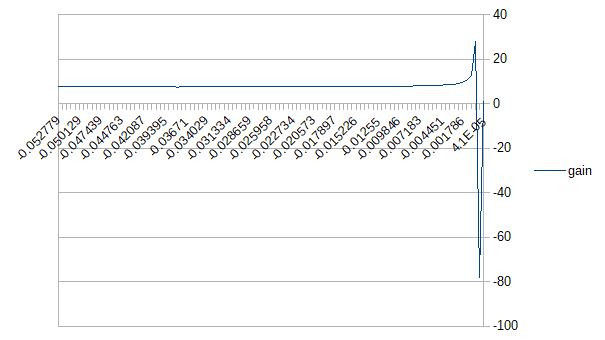

And a graph of the OpAmps gain, with as axis the shunt voltage.

Top Comments

-

Jan Cumps

-

Cancel

-

Vote Up

+3

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

Andrew J

in reply to Jan Cumps

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

Jan Cumps

in reply to Andrew J

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

Andrew J

in reply to Jan Cumps

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

Jan Cumps

in reply to Andrew J

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

Jan Cumps

in reply to Andrew J

-

Cancel

-

Vote Up

+1

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

-

jc2048

in reply to Andrew J

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

jc2048

in reply to Andrew J

-

Cancel

-

Vote Up

+2

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children