Very bad and shaky video quality, but I've decided to upload this 2-minute video anyway, in case it helps anyone, because I struggled for years with hot air tools, and it only slowly dawned on me the issues I'd had were related to things like no pre-heating and severely underpowered (300W from memory) hot-air tool.

Any tips will be gratefully appreciated! Nothing in this video is best practice; I'm just a beginner. It's definitely not normal to apply paste on a pre-heated board for instance, but it seems to prevent the paste from drying up rapidly (and I am using several-year-expired paste).

The video shows capacitors being soldered using the hot-air tool, to a thick copper 4-layer PCB. The soldering iron struggled with it, so I decided to use the hot air tool instead. The video doesn't actually show the placement of the capacitors, but that was just done with tweezers, placed on top and lightly tapped to make sure they were sitting in the solder. I needed two hands for that, and I was shooting video handheld.

Whether the capacitors work or not I have no idea! : ) That's yet to be seen. I was trying to heat evenly, because they can very easily crack and go open- or short-circuit.

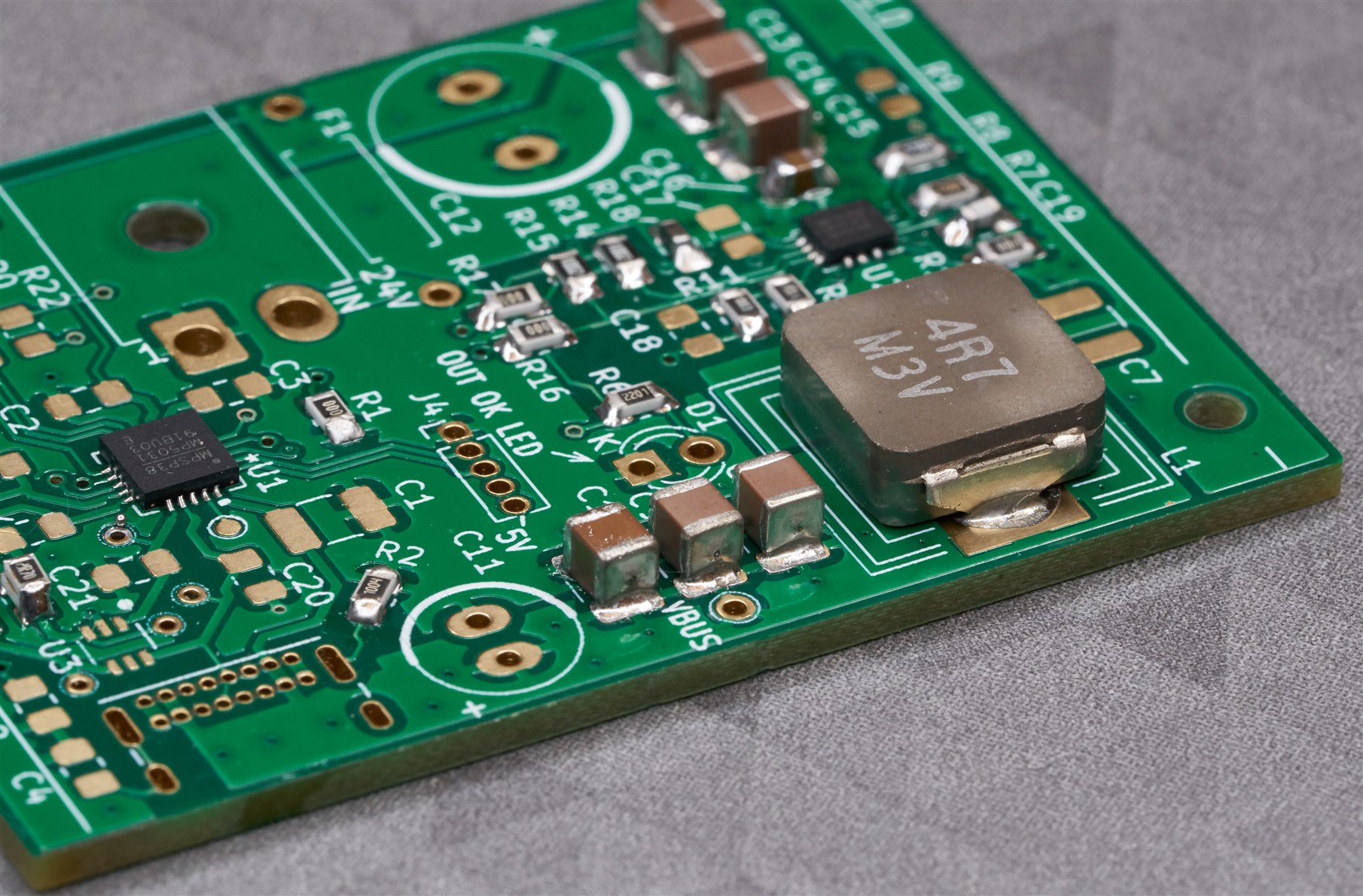

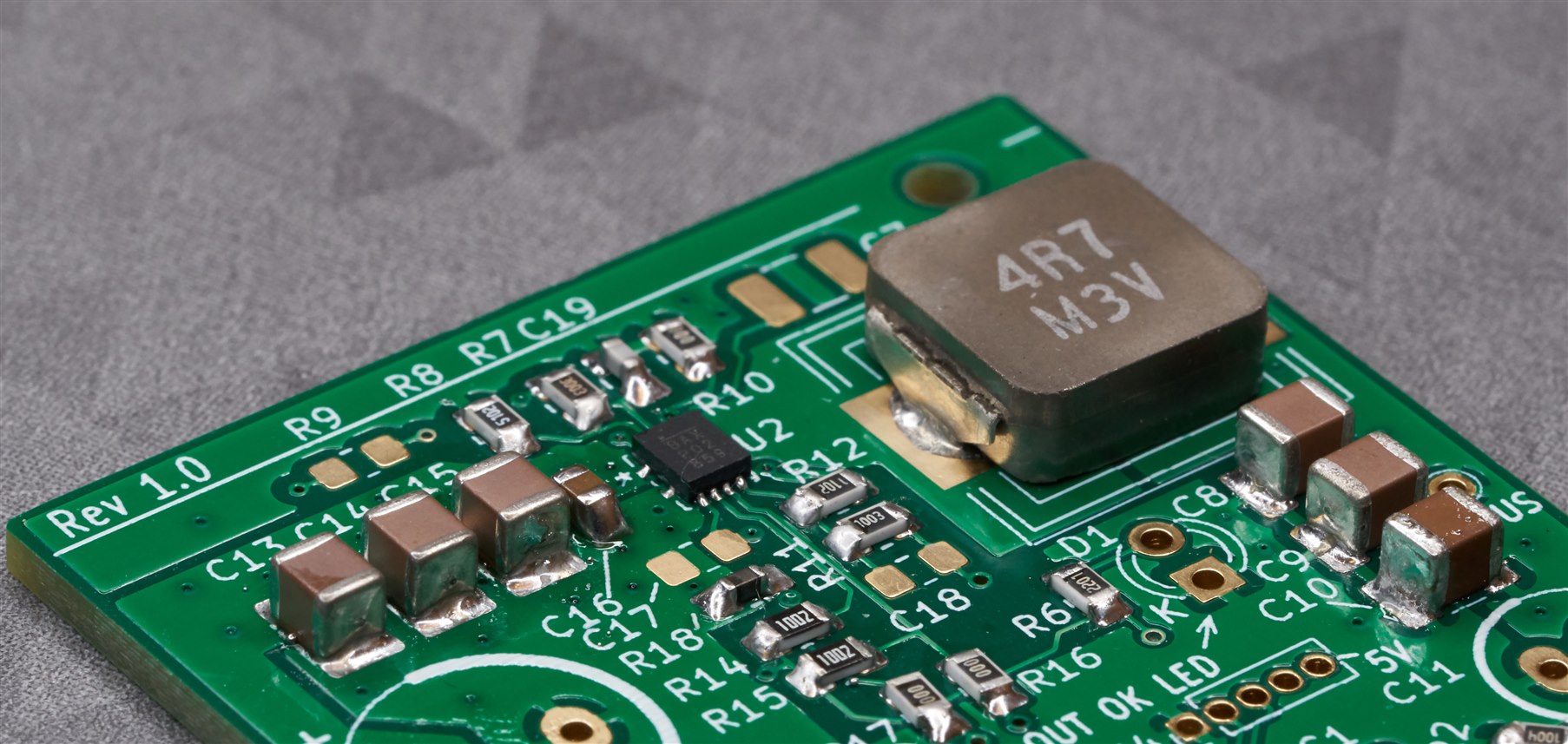

Photos of the board:

View from a different angle; the board is still a work-in-progress, still things to solder, but the rest can mostly be done with a soldering iron.

Top Comments