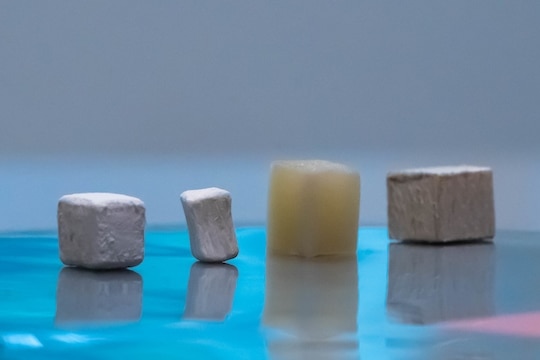

Wood pieces at different stages of modification, from natural (far right) to delignified (second from right) to dried, bleached, and delignified (second from left) and MOF-infused functional wood (first on the left). (Image Credit: Gustavo Raskosky/Rice University)

Structural materials such as cement and steel are costly and produce carbon dioxide emissions. An estimated 40% of emissions come from its use and building construction. Replacing those standard materials with sustainable alternatives could reduce carbon emissions. Rice University scientists created functional wood that pulls carbon dioxide from the air.

"Wood is a sustainable, renewable structural material that we already use extensively,"

Muhammad Rehman, an assistant research professor in materials science and nanoengineering at Rice University, said. "Our engineered wood did exhibit greater strength than normal, untreated wood."

The team delignified the wood, a process that involves extracting lignin and cellulose fibers, to provide a porous structure. "Wood is made up of three essential components: cellulose, hemicellulose and lignin," Rahman said. "Lignin is what gives wood its color, so when you take lignin out, the wood becomes colorless. Removing the lignin is a fairly simple process that involves a two-step chemical treatment using environmentally benign substances. After removing the lignin, we use bleach or hydrogen peroxide to remove the hemicellulose."

Natural wood (left) compared to delignified wood (right). (Image Credit: Gustavo Raskosky/Rice University)

They then soaked the porous structure into a solution containing Metal-Organic Framework (MOF) particles, a highly absorptive material. The chosen Calgary framework 20 (CALF-20) MOF has a higher performance and versatility in different environments compared to its counterparts. "The MOF particles easily fit into the cellulose channels and get attached to them through favorable surface interactions," said Soumyabrata Roy, a Rice research scientist, and lead author of the study.

Using the top-down method made it possible for the team to produce a structure closely resembling wood and easily infuse the whole structure with the material. Their end product is a wood structure capable of collecting and storing carbon dioxide with high selectivity over water vapor and nitrogen.

"Right now, there is no biodegradable, sustainable substrate for deploying carbon dioxide-sorbent materials," Rahman said. "Our MOF-enhanced wood is an adaptable support platform for deploying sorbent in different carbon dioxide applications."

The wood structure can be developed with today's technology and has many applications, including construction, furniture manufacturing, and an environmentally friendly option substituting conventional materials. Next, the researchers expect to perform an economic analysis to understand the material's commercial viability and scalability.

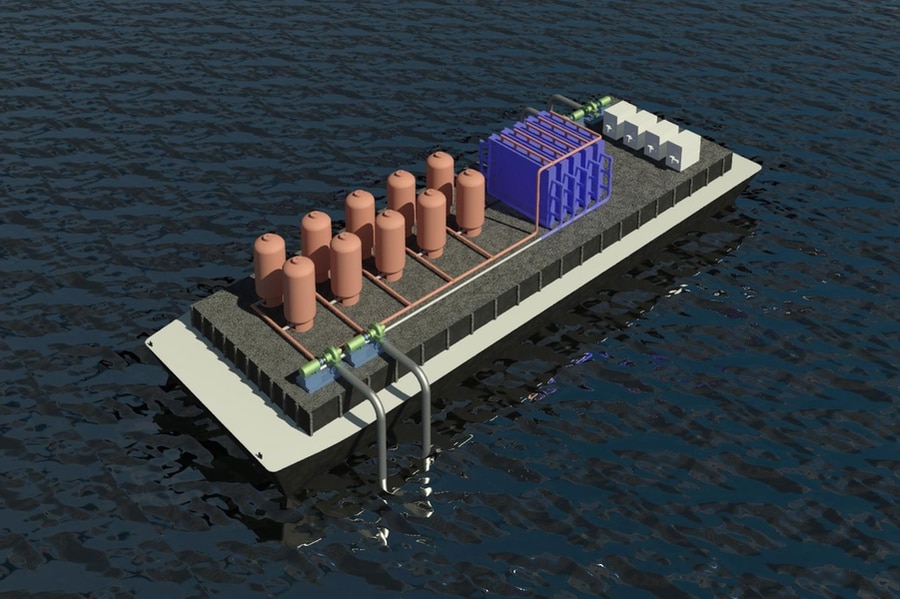

MIT researchers developed a system that pulls out carbon dioxide from the oceans. (Image Credit: MIT)

MIT researchers developed a new energy-efficient system that captures and releases the ocean's carbon dioxide. This solution is more affordable and efficient than traditional direct air capture systems.

The team's system involves a reversible process with two membrane-free electrochemical cells. First, reactive electrodes release protons into the seawater, converting inorganic bicarbonates into molecular carbon dioxide that gets harvested with a vacuum. The water then moves through another set of cells that have a reversed voltage, which recovers the protons and converts the acidic water into alkaline before releasing it into the sea. Both cells' roles reverse when one set of electrodes no longer has protons, and the other regenerates during alkalization.

Carbon dioxide still needs to be disposed of after removal. It can either be transformed into a transportation fuel like ethanol or buried in deep formations under the sea floor. "You can certainly consider using the captured CO2 as a feedstock for chemicals or materials production, but you're not going to be able to use all of it as a feedstock," says MIT professor T. Alan Hatton. "You’ll run out of markets for all the products you produce, so no matter what, a significant amount of the captured CO2 will need to be buried underground.”

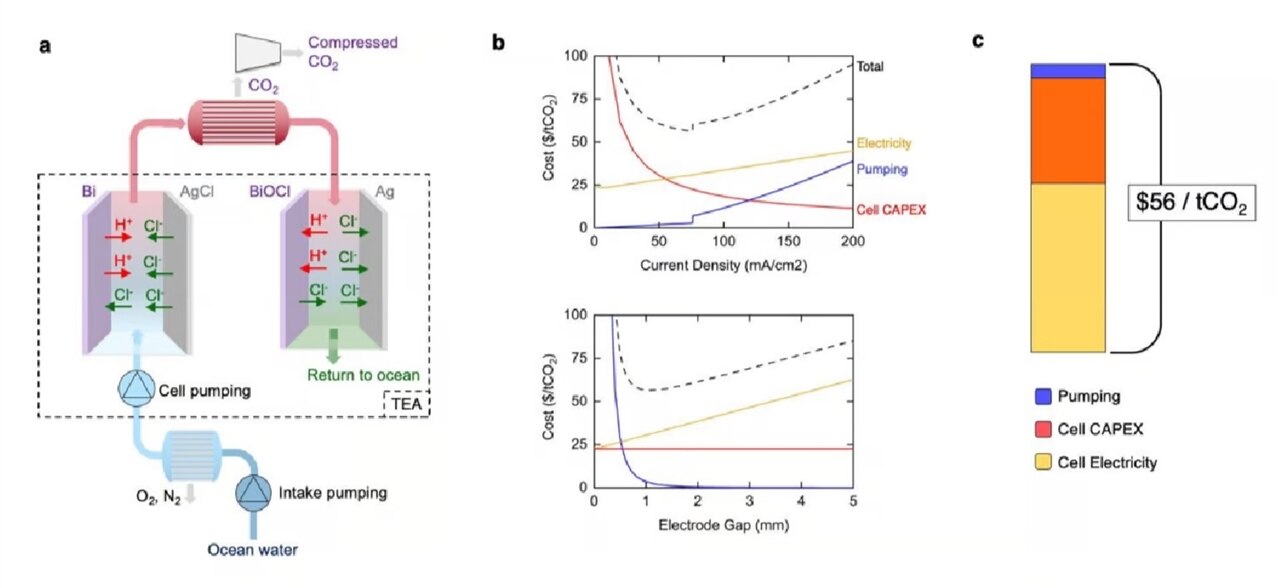

Device schematic (left), current density and electrode gap optimization (center), and cost efficiency of the carbon capture system (right). (Image Credit: MIT)

Offshore drilling platforms or aquaculture farms could also use the system. Additionally, the device could be integrated into ships, helping reduce emissions from ship travel. International mandates are in place to help reduce emissions, and “this could help shipping companies offset some of their emissions and turn ships into ocean scrubbers,” MIT professor Kripa Varanasi says.

The researchers say the system could have an optimized cost of $56 per ton of carbon dioxide captured. However, this does not consider vacuum degassing, filtration, and auxiliary costs outside the electrochemical system. Those can be mitigated by Installing this carbon capture system in desalination plants and other facilities.

In addition, it could help solve the acidification problem occurring in the ocean due to carbon accumulation that also impacts coral reefs. The team plans to demonstrate this technology within two years but notes it still needs improvements. They want the system to separate the gas without a vacuum.

Have a story tip? Message me at: http://twitter.com/Cabe_Atwell