The purpose of this blog is to assess the compliance status of IP68-rated enclosures over time by conducting a series of tests. The tests will analyze the impact of extreme environmental conditions on the electronics within the enclosure using electronics described in this blog series.. Data will be reported/transmitted for analysis, reporting, and real-time monitoring, providing insights into enclosure performance and reliability, with potential applications in outdoor electronics, marine equipment, and industrial machinery.

As part of a Design Challenge titled Experimenting with Extreme Environments, sponsored by Hammond Manufacturing, I composed this extra credit blog. This blog is the 5th and final in a series of extra credit entries that address crucial steps taken towards my final challenge blog, Final Results -- IoT Device Protection in Harsh Environments

The reliability evaluation is a critical component of ensuring the sustained functionality and durability of electronic components housed within the waterproof enclosure. Through the execution of these tests, the objective is to assess the enclosure's Ingress Protection (IP) rating and evaluate its efficacy in safeguarding the electronics from diverse environmental factors. Testing Procedures include the following:

Thermal Exposure: Subject the enclosure to extreme temperatures, ranging from sub-zero cold to intense heat, to analyze its resilience to thermal variations.]

Water Immersion: Immerse the enclosure in water for a prolonged duration to assess its water resistance and ability to withstand submersion.

Humidity Resistance: Place the enclosure in a controlled humidity chamber to evaluate its performance in humid environments.

Environmental Monitoring: Monitor temperature and humidity levels inside the enclosure during testing to ensure that electronic components are not exposed to excessive conditions.

Condensation and Moisture Evaluation: Record any condensation or moisture accumulation within the enclosure to assess the effectiveness of its sealing mechanism.

The enclosure with the electronics is exposed to the following conditions.

Extreme Temperatures: Evaluating the enclosure's ability to protect the electronics from extreme cold and heat, which can cause damage to delicate components.

Moisture: Assessing the enclosure's resistance to moisture ingress, which can lead to corrosion and malfunction of electronic components.

Humidity: Determining the enclosure's ability to withstand high humidity levels, which can cause condensation and affect the performance of electronic components.

Dust: Exposing the enclosure to dust particles to assess its ability to prevent dust ingress, which can interfere with the functionality of electronic components.

Light: Evaluating the enclosure's resistance to prolonged exposure to sunlight and UV radiation, which can cause discoloration and degradation of materials.

Each test will adhere to the following structure to ensure consistency and thoroughness in reporting the results:

- Test Name: This section will specify the unique identifier or name assigned to the particular test being conducted.

- Python Script Name: this is the name of the Python script used to run the test

- Testing Exposure to: Here, the specific factor or condition being tested will be stated. This could include exposure to: Extreme Temperatures, Moisture, Humidity, Dust, Light:

- Description: In this section, a detailed description of the test setup, methodology, and procedures employed during the experiment will be provided. This includes information about the test, experimental conditions, and any relevant parameters.

- Results: The findings and observations gathered during the test will be presented in this section. This may include numerical data, statistical analysis, graphs, or any other relevant information that contributes to the understanding of the test outcomes.

- Conclusions: Based on the results obtained, conclusions will be drawn regarding the effects or impact of the exposure being tested. This section will summarize the key findings and their significance, often in relation to the initial hypotheses or objectives of the test.

This structured outline ensures that each test is conducted in a systematic and reproducible manner, facilitating clear and concise reporting of the findings. It also allows for easy comparison and analysis of different tests, contributing to the advancement of knowledge and understanding in the relevant field.

The Reliability Test

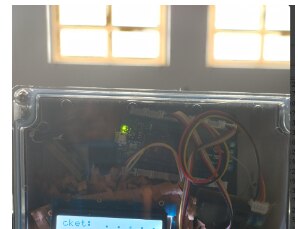

To do reliability test I will use the “ Headless setup” that I described in Blog#4 in this series.

- Connect to the CM4 over an WiFi IP address, using a terminal (PuTTY) program running from a PC or Linux system. Make certain that you use the WiFi ip address, not the inet ip.

- Login to the CM4

- Run the examples.

To run the examples, first switch to your virtual environment using the command:

source ~/.virtualenvs/pimoroni/bin/activate

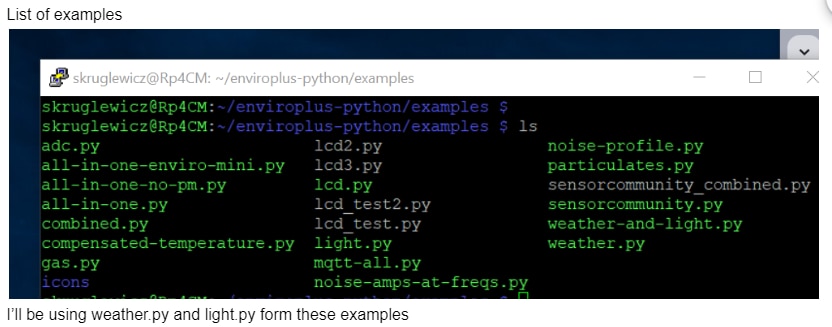

The examples are available in the examples folder within the enviroplus-python folder. To view and run the available examples in the terminal, type the following commands:

cd enviroplus-python cd examples ls

When running the examples, press at any time to stop the example.

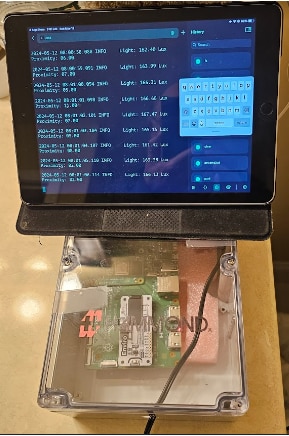

My test setup running the light.py example. I’m using my iPad running the “Termius” app to connect to the CM4 in the hammond enclosure. This setup is what I’ll use to run the Reliability test in this blog

TEST1

Test Name: In the Freezer

Python Script Name: weather.py

Testing Exposure to: Extreme Temperatures

Description: I placed the case in our Freezer with the other frozen foods. The inside case temperature was down below Zero Fahrenheit.

Photo(s):

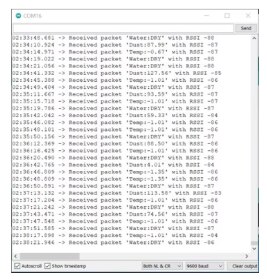

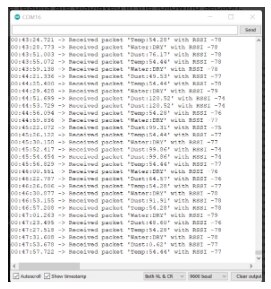

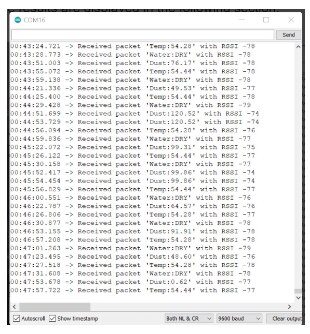

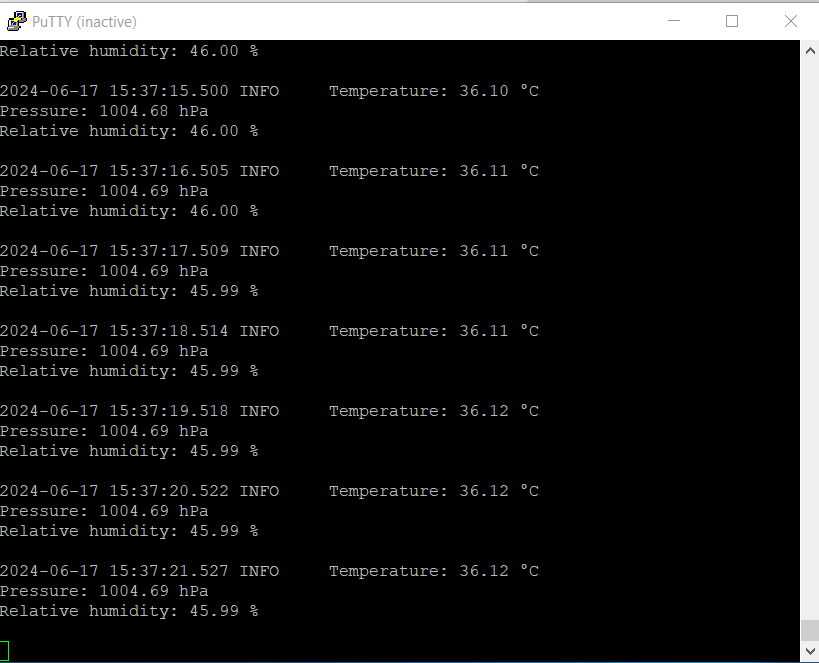

Results: this is an example of the terminal screen

Conclusions: Test was successful. The electronics were not affected by the cold temperatures.

TEST2

Test Name: In Water

Python Script Name: weather.py

Testing Exposure to: Moisture, Humidity

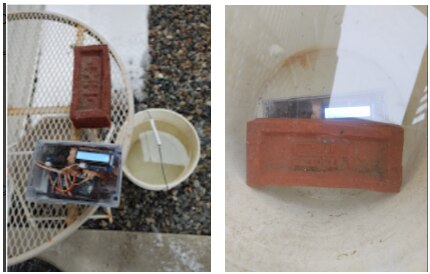

Description: In an external setting, I submerged the testing enclosure in a bucket of water. A brick kept the case secured.

Photo(s):

Results:

Conclusions: I was unable to test this because i did not feel comfortable submerging the enclosure in water with a tapped up hole with the power cord coming through. The photos were taken in during my other experiments with a watertight Hammond enclosure from another challenge.

TEST3

Test Name: In the Garage

Python Script Name: weather.py

Testing Exposure to: DUST, Temperature, Humidity

Description: I placed the Enclosure in the Garage. It was in the garage for about 8 hours. The temperature stayed around 52F degrees inside the enclosure. you can observe the dip in the temp chart on the dashboard below. It was a bit colder outside of the garage.

Photo(s):

Results:

Conclusions: despite the warm temperatures and high humidity in the garage the electronics did not over heat. I was not able to get the Dust sensor to work , so I did not test for dust in this experiment.

TEST4

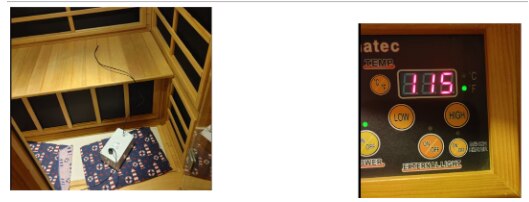

Test Name: In a Sauna

Python Script Name: weather.py

Testing Exposure to: Extreme Temperatures, Moisture, Humidity,

Description: This test was to place the enclosure into my personal sauna

for about 6 hours. I was able to get the Temperature in the Sauna up to 107F degrees.

Photo(s):

Results:

Conclusions: Also despite the warm temperatures and high humidity in the space the electronics did not over heat.

TEST5

Test Name: Between the Front Doors.

Python Script Name: weather.py

Testing Exposure to: Extreme Light ,Extreme Temperatures. Humidity

Description: The space between my front door and the glass storm door can get real HOT in the morning. The space will be used to test the Conditions

Photo(s)

Results:

Conclusions: Also despite the warm temperatures and high humidity in the space the electronics did not over heat.

BLOG CONCLUSIONS

This blog post details a series of reliability tests conducted on IP68-rated enclosures to assess their ability to protect electronics from extreme environmental conditions. The tests involve exposing the enclosures to various conditions such as extreme temperatures, moisture, humidity, dust, and light. The testing methodology includes a structured outline for each test, specifying the test name, Python script used, exposure conditions, a description of the setup, and the results and conclusions drawn from the experiment. The blog post outlines several tests conducted, including placing the enclosure in a freezer, submerging it in water, and exposing it to dust, temperature, and humidity changes in a garage. Future tests will involve exposing the enclosure to extreme heat in a sauna and intense light between glass doors.

The reliability tests conducted on the IP68-rated enclosures aimed to assess their ability to protect electronics from extreme environmental conditions, takeaways include:

- Resistance to extreme temperatures: The enclosures were able to withstand exposure to both freezing temperatures in a freezer and high temperatures in a garage, suggesting that they offer good protection against thermal variations.

- Water resistance: Submerging the enclosure in water did not result in any moisture ingress, demonstrating its effectiveness in preventing water damage to the enclosed electronics.

- Dust and humidity resistance: Exposing the enclosure to dust and humidity in a garage did not significantly affect its performance, indicating its ability to protect against these environmental factors.

- Exposure to extreme heat in a sauna and intense light between glass doors. These additional tests will provide a more comprehensive understanding of the enclosures' performance under diverse conditions.

Overall, the reliability tests suggest that the IP68-rated enclosures offer a good level of protection for electronics in various environmental conditions. However, further testing is needed to fully evaluate their performance and identify any potential limitations.

RESOURCES

Just Encase

For this challenge Just Encase, I created a blog series called “Case Enclosure Reliability Monitor”. If anyone is interested in this series, Blog#1 - Introduction is a starting point for the series. It contains an introduction and a table of contents to the other blogs. In this blog post, I introduce the Design Challenge, which involves two useful sensors capable of detecting moisture and dust. Although the challenge utilized Arduino MCUs, that aspect is not relevant to the current discussion, but this blog post BLOG#5 Testing Part 2 , describes how I utilize the two sensors. The code is written for Arduino, however I give some references to the sensors: Grove - Dust Sensor(PPD42NS)and a Grove - Water Sensor