As part of a Design Challenge titled Experimenting with Extreme Environments, sponsored by Hammond Manufacturing, I submitted this blog as the final results blog. This is the last blog in a series of extra credit blogs that cover topics of major steps taken to get to my final results for the challenge. This project is a thorough revamp of my earlier "Just Encase" challenge Blog Series submitted to the Element14 community. The project was sponsored by Hammond Manufacturing and utilized two Arduino MKR WAN 1300 MCUs.as IoT devices. The knowledge and experimentation gained during the Design Challenge will be valuable in the current "Experimenting with Extreme Environments" challenge.

The Challenge Objective

The main objective of this challenge is to test the durability of electronic placed in a HAMMOND enclosure in extreme environments. In a Harsh environment, IoT devices are being exposed to conditions that can shorten their lifespans, such as extreme temperatures, moisture, humidity, vibrations, chemicals, impacts, and dust.

Participants of this challenge are tasked with the following:

- Use an electronic parts kit, including an IP68-rated enclosure.

- Design and build an electronic system using the electronic parts and house it in the enclosure.

- Develop experiments to test the enclosure's durability under various extreme environmental conditions.

- Determine additional sensors needed to construct the testing systems.

Parts Kit

Description

- Electronic components

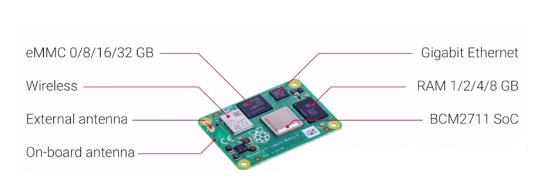

- Pi4 Compute Module

- Pi4 Compute Module I/O Board

- Display, Alphanumeric, 20X4 (not used)

- Antenna, WiFi, BLE, Thread, Wireless Hart, Zigbee

- HAMMOND Enclosure

- Circular Connector, Cable Mount Receptacle, 4 Contacts

- Circular Connector, Cable Mount Plug, 4 Contacts

- Circular Connector, Panel Mount Receptacle, 4 Contacts

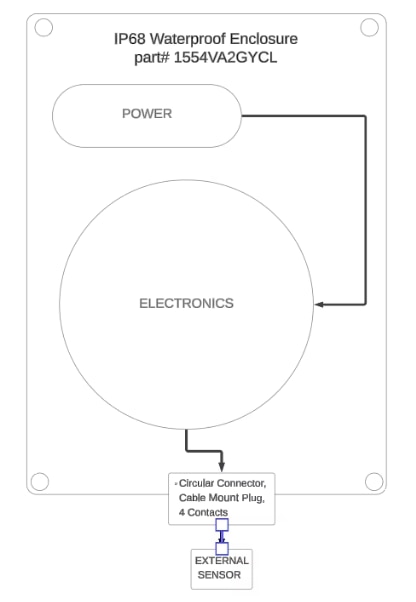

- IP68 waterproof Enclosure part# 1554VA2GYCL

- Attached to the Enclosure through a pre-drilled hole

Please note that the challenge kit lacks certain components required for the competition idea. Participants must possess the necessary resources, equipment, and minor parts to construct their testing systems. To enhance the sensing capabilities of the Pi4 electronics, I incorporated sensors from my previous IoT project.

Unboxing

The package arrived April 2,2024

The package included the following items

1.Pi4 Compute Module

First up, we have the Pi4 Compute Module. This is the brains of our project. It's a quad-core 64-bit processor. It Features wireless connectivity, 4GB RAM, 0GB(Lite) eMMC storage

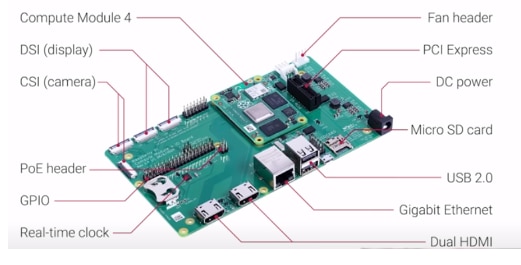

2. Pi4 Compute Module I/O Board

Next, we have the Pi4 Compute Module I/O Board. This board provides the necessary connections for the Pi4 Compute Module, including HDMI, USB, and Ethernet.

3. Display, Alphanumeric, 20X4

This is a 20-character by 4-line alphanumeric display. It's perfect for displaying information like temperature, humidity, and other sensor data.

4. Antenna, WiFi, BLE, Thread, Wireless Hart, Zigbee

This antenna will allow the Pi4 Compute Module to connect to the internet and other devices wirelessly.

5. Enviro - Indoor Monitor (Pi-Mor-O-ni)

This did not come with the kit But I might use it. This indoor monitor is a great way to track temperature, humidity, and air quality. It is a Pi Hat that could be attached to the PoE header of the CM4IO carrier card.

HAMMOND Enclosure

- IP68 waterproof Enclosure part# 1554VA2GYCL

- Circular Connector, Cable Mount Receptacle, 4 Contacts

- Circular Connector, Cable Mount Plug, 4 Contacts

UNBOXING VIDEOS

- This video Describes the Unboxing of the Parts kit used in the element 14 Experimenting with Extreme Environments challenge

Unboxing Video Part 1 https://youtu.be/XGrGdNGZAL0

- In this video, I will be describing the Parts that I unboxed In part 1

Unboxing Video Part 2 https://youtu.be/FX33W9fRaVQ

My Idea

Leveraging the provided components, I envisioned a monitoring dashboard that would furnish reports on the compliance status of the supplied Case IP68 ratings over time. Additionally, it would analyze the impact of the IP68 rating on the electronics housed within the enclosure when subjected to extreme environmental conditions.

The idea is to conduct a number of tests to determine if the Ingress Properties Ratings of the supplied enclosure is met. This project involves developing a monitoring system to assess the compliance status of IP68-rated enclosures over time. The system will analyze the impact of extreme environmental conditions on the electronics within the enclosure using sensors and a microcontroller. Data will be transmitted to a dashboard for analysis, reporting, and real-time monitoring. The system's benefits include providing insights into enclosure performance and reliability, with potential applications in outdoor electronics, marine equipment, and industrial machinery.

Implementation of my Idea

VIDEO DEMONSTRATION

If you want to follow through and learn how I came up with the implementation of my idea, you can refer to the following Extra credit Blogs in the next 5 sections. These blogs cover Topics of major steps taken to get to the implementation video shown in the above “Implementation” Section.

Blog#1 Design

The goal of this blog to describe my design of my initial idea, for an element14 Design Challenge. It will describe the functionality and the technical aspects of my idea. My idea is to conduct a number of tests to determine the Ingress Properties Ratings of a Hammond enclosure.

Blog#2 Deep Dive into the Electronic IoT Parts

The goal of this blog is to take a deep dive into the electronic parts supplied by Hammond for the challenge. Before I can use the parts for my project, I need to understand how the parts fit together.

Blog#3 Deep Dive into the Hammond Enclosure

In this blog post, I will delve into the IP68 Waterproof Enclosure offered by Hammond. The IP68 rating signifies that the enclosure is dust-tight and can withstand prolonged immersion in water at a depth of 1.5 meters for up to 30 minutes.

The Enclosure is crafted from high-quality polycarbonate, a lightweight and durable material that offers excellent impact resistance. The enclosure's seamless gasket and locking system create an airtight seal, ensuring that no moisture or dust can penetrate the interior. Additionally, the enclosure is UV-resistant, making it suitable for outdoor applications where exposure to sunlight is a concern.

In summary, the IP68 Waterproof Enclosure by Hammond is a versatile and dependable solution for applications that demand protection from moisture, dust, and other environmental hazards. Its rugged construction, airtight seal, and UV resistance make it an ideal choice for a wide range of industries, including marine, outdoor electronics, and industrial automation. Whether it's protecting sensitive electronics in harsh environments or enabling underwater exploration, the IP68 Waterproof Enclosure continues to impress with its exceptional performance and reliability.

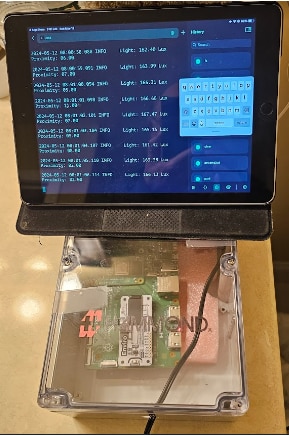

Blog#4 Implementation of Electronic Parts

This blog describes the construction of the electronics that will be housed within the enclosure. The purpose of this is to test the effects of the environment on the electronics.

In this blog post, I will delve into the intricacies of constructing the electronic components that will be safely housed within the enclosure. The primary objective of this endeavor is to examine the potential impacts of various environmental factors on the functionality and performance of these electronic systems. The electronics are subjected to various electrical, thermal, and mechanical stresses to assess their robustness and durability.

The assembled electronics are then integrated into the enclosure, which provides a protective barrier against external elements. The enclosure is designed to safeguard the electronics from moisture, dust, vibrations, and other environmental hazards.

I aim to create a controlled environment that enables the systematic study of environmental effects on electronic systems. The data collected from these experiments will contribute to a better understanding of how various environmental factors, such as temperature, humidity, and electromagnetic interference, can impact the performance and reliability of electronics

Blog#5 Testing the Environment within the Waterproof Enclosure

The purpose of this blog is to assess the compliance status of IP68-rated enclosures over time by conducting a series of tests. The tests will analyze the impact of extreme environmental conditions on the electronics within the enclosure using electronics described in this blog series.. Data will be reported/transmitted for analysis, reporting, and real-time monitoring, providing insights into enclosure performance and reliability, with potential applications in outdoor electronics, marine equipment, and industrial machinery.

CONCLUSIONS

Give some conclusions as to what I have gained from this Design Challenge. Answer some questions: Did everything work as designed? What were the biggest hurdles you had to overcome?

This document summarizes a project testing the durability of electronic devices in harsh environments. The project used a kit provided by Hammond Manufacturing, including an IP68-rated enclosure and various electronic components. The main objective was to test the enclosure's durability in extreme conditions like temperature fluctuations, moisture, and vibrations. I conducted several tests to assess the enclosure's Ingress Protection (IP) ratings and monitor its performance over time. The project involved developing a monitoring system to track the enclosure's condition and the impact of environmental factors on the electronics inside. Data from the tests would be transmitted to a dashboard for analysis and reporting.

The document outlines the project's steps, including unboxing the kit, describing the components, and explaining the experimental setup. It also mentions extra credit blogs that provide more details on the design, implementation, and testing processes. The author concludes by reflecting on the lessons learned and suggesting potential enhancements for future work.

FUTURE ENHANCEMENTS

I present a list of possible enhancements that can be added to make the system more useful.

- Integrate with existing monitoring systems or platforms using standard communication protocols such as MQTT or HTTP. This would allow for the data collected by the system to be easily shared with other systems, providing a more comprehensive view of the environment. Additionally, the use of cloud-based platforms could allow for easier data storage, analysis, and visualization. This would enable users to access the data from anywhere and gain insights into the long-term performance of the enclosure and the electronics within it.

- Improved sensor diversity: Incorporate a wider range of sensors to monitor additional environmental factors such as air quality, light intensity, or specific gasses. This would provide a more comprehensive understanding of the enclosure's operating conditions.

- Predictive maintenance: Utilize machine learning algorithms to analyze the collected data and predict potential failures or maintenance needs. This would allow for proactive intervention, reducing downtime and repair costs.

- Remote management and control: Implement a web-based interface or mobile app to enable users to remotely monitor the system, configure settings, and receive alerts. This would provide greater flexibility and convenience for users who may not have physical access to the enclosure.

- Edge computing capabilities: Process data locally within the enclosure using edge computing devices. This would reduce latency, improve responsiveness, and enable real-time decision-making in critical situations.

- Enhanced security features: Implement encryption, authentication, and authorization mechanisms to protect the system from unauthorized access and data breaches. This is especially important for systems that handle sensitive information or operate in critical environments.