Self-Intro:

I am Karthik Rajagopal, pursuing my UG course on Electronic Engineering. I am currently working as a Hardware Engineer in a Start-up company as a part of my Internship. I have come across a lot of designs and design constraints in electronics which has led me to learn further and expand my knowledge in Circuit designing. Keeping up with the present-day technology is one of the key aspects that has helped me progress.

My experience with Thermal Switches:

Though my field of work does not involve much of power electronics, I have found many situations which needed the application of Thermistors and Thermal switches. One such application I have worked with is a battery charger. The popular use of Thermistors for soft starting was needed in that circuit. Another application was to have 3 stages of controlled heating in a water heater which was accomplished by Thermal Switches. Since they have a fixed cut off temperature and can directly be wired up to mains voltage, the whole design cost drastically reduced. A simple network of 5 to 6 thermal switches were used to create heating stages with two thresholds.

Problem in current technology:

I recently came across a post about the evolution of LED technology from just being an indicator light to the wide spectrum of applications it is currently used in. Among those, using them as lighting solution has a good impact on our environment compared to the conventional CFL and Tungsten based lighting.

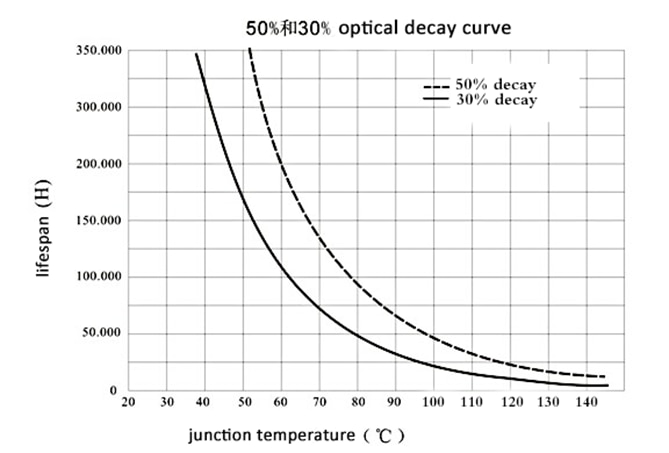

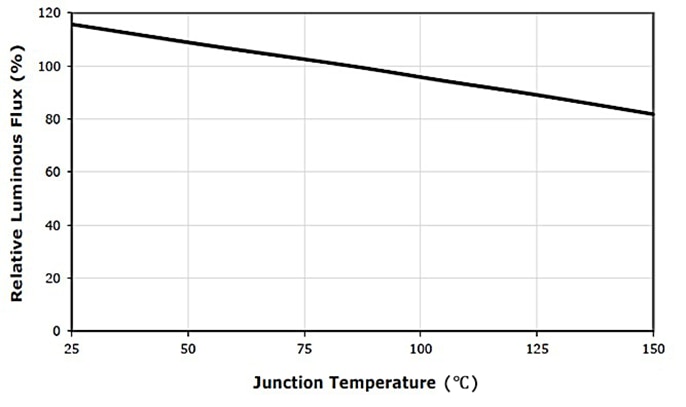

While having a better luminous flux to current ratio, the life of those LEDs is limited by a few factors. One such factor is heat. With time, the heat in the LED lamps we use reach a temperature which when operated in the same condition affects the life of the LED bulb.

Source: https://www.agcled.com/blog/the-application-of-outdoor-led-lights-in-cold-places.html

My Solution and Test Procedure:

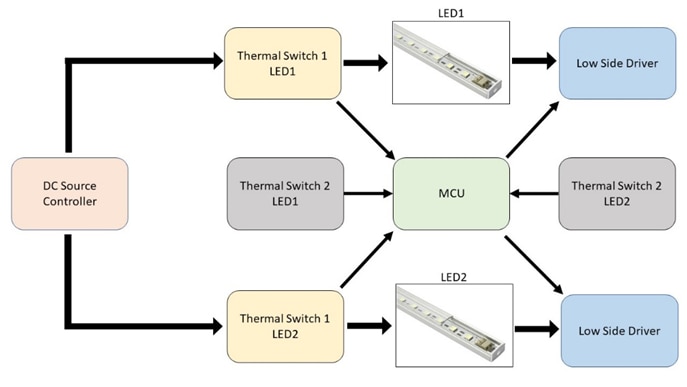

My solution to the above problem is to switch between two sets of lighting panel inside the same unit based on heat. This will ensure a better LED life while also maintaining the brightness after switching. The switching will be done by the Thermal switches provided by KEMET.

The threshold temperature will be identified and an appropriate switch will be attached to the heat sink of the LED panels.

The circuit will be utilizing a pair of Thermal Switches for each LED strip. This is done to ensure a smooth transition from LED1 to LED2 after reaching the threshold.

The Microcontroller (An Arduino in my case) will take care of the timing aspects in switching.

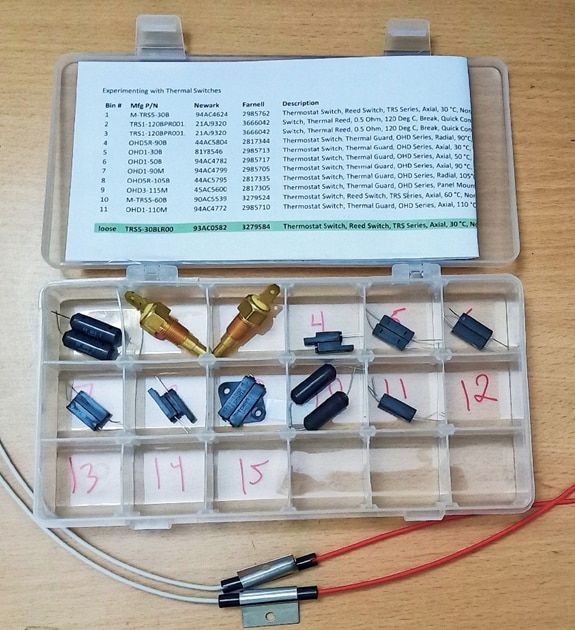

KEMET Switches:

The kit of 11 Thermal Switches was very well packed and labelled. I will be testing out the thermal switches with Curie temperature from 30°C to 90°C. Based on hysteresis of the switches, the cut off temperature and timing will be decided.

Top Comments